Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

August 1, 2011

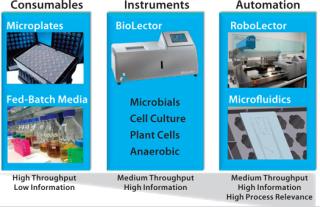

Continously new bioprocesses are evolving, and bioprocessors are searching for the easiest way to process samples in R&D. Currently, a huge trend towards disposable production systems is notable. For these purposes plastic bags, stirred-tank reactors, and storage tanks established on the market. Unfortunately, these reactor types are not suitable to perform sophisticated bioprocess development. In bioprocess R&D, throughputs of 50 to 1,000 fermentations are needed. Therefore, m2p-labs developed intelligent new tools at microscale to fulfill the needs in bioprocess development. The combination of high-throughput experimentation, online monitoring, scalability, and automation made it possible to provide unique and very efficient bioprocessing tools at microscale. Our mission is to bring bioprocesses as fast as possible from microreactor to process — m2p.

BioLector® Technology

The Biolector is a unique high-throughput fermentation system. In 48 parallel cultures, the most important fermentation parameters such as biomass concentration, pH, and Do — as well as fluorescent proteins or substrates — can be all monitored online. Most important, the system is very easy to handle. The disposable and precalibrated microplates can be immediately installed in the Biolector after medium inoculation. The incubation chamber allows for control of temperature, humidity, and specific gas concentrations (O2, Co2, anaerobic, microaerophilic, syngas). The device is approved for microbial, mammalian, plant, human, and anaerobic cells.

Flowerplate®

The Flowerplate was designed to provide high oxygen mass transfer (OTR > 0.150 mol/L/h). This is achieved by a patented flower shape of the wells on a standard microplate footprint. Microbial cells can be operated in microscale under oxygenunlimited culture conditions in 48 parallel microbioreactors. Good mass transfer conditions are the prerequisite for scale-up to stirred-tank bioreactors, which is a must when working at microscale. The standard microplate format allows for automation in standard liquid handling systems and for even higher parallelization on common laboratory shakers.

Feed in Time™: Fed-batch Media

Fed-batch processing is the most abundant technology in bioproduction processes. Nevertheless, clone screening and bioprocess development are still conducted in batch mode due to limited technology availability at small scale. The “Feed in Time” fed-batch media series resolve this fundament problem. Now it is possible to apply also in small and microscale glucose-limited growth in fed-batch mode. m2plabs offers synthetic and complex ready-to-use media for Escherichia coli, Bacillus subtilis, Pichia pastoris, and Hansenula polymorpha. Further media are in development and can be customized on request.

RoboLector™

The RoboLector is a combination of a (pipetting-) robot and the Biolector. It can be integrated into standard liquid handling systems such as those from Tecan, Hamilton Robotics, Perkin Elmer, Beckman, and others. Hence, it is possible to automate upstream bioprocessing completely. The system can be used for media preparation, automated sampling, induction, and fed-batch processing. The RoboLector brings reproducibility and reliability into any biological experiment and is ideally suited to incorporate DoE plans. The systematic use of this system provides detailed process understanding and is a very useful tool for QbD and PAT.

About the Author

Author Details

Dr.-Ing. Frank Kensy is managing director at m2p-labs GmbH, Arnold-Sommerfeld-Ring 2, 52499 Baesweiler/Aachen, Germany; +49-2401-805330; [email protected]www.m2p-labs.com.

You May Also Like