Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

In the field of research and development into the production of bioactive compounds, there is incredible demand for small-scale cultivation systems that operate in the liter range (1, 2). Single-use bag bioreactors can close the gap between cell and media screening devices (at scales of up to several hundreds of milliliters) and pilot bioreactor systems at scales larger than several hundreds of liters (3). The incubator shaker Multitron Cell with ShakerBag Option, in particular, represents an easy and economical solution for increasing cultivation volumes beyond classical shake-flask scales without the need to purchase a bioreactor system. Besides the general advantages that arise from the single-use design of these bag bioreactors (4), they are also characterized by reduced foam formation and flotation due to the surface aeration (4, 5) that plays an important role in plant cell suspension-based processes.

In the field of research and development into the production of bioactive compounds, there is incredible demand for small-scale cultivation systems that operate in the liter range (1, 2). Single-use bag bioreactors can close the gap between cell and media screening devices (at scales of up to several hundreds of milliliters) and pilot bioreactor systems at scales larger than several hundreds of liters (3). The incubator shaker Multitron Cell with ShakerBag Option, in particular, represents an easy and economical solution for increasing cultivation volumes beyond classical shake-flask scales without the need to purchase a bioreactor system. Besides the general advantages that arise from the single-use design of these bag bioreactors (4), they are also characterized by reduced foam formation and flotation due to the surface aeration (4, 5) that plays an important role in plant cell suspension-based processes.

Identifying engineering parameters such as mixing time, oxygen mass transfer, and power input is important to define suitable operating parameters. However, these parameters are depend heavily on the viscosity of the liquid. Therefore, sodium carboxymethyl cellulose (Na-CMC) solutions were used as appropriate model systems for mimicking plant-cell suspensions because they exhibit almost identical rheological behavior. Engineering parameters were determined for three different cell growth stages, which represent optimal operating parameters for the orbitally shaken bags at scales of 2 L and 20 L. Depending on the growth stage, the shaking frequencies were set to values between 40 and 70 rpm and 30 and 65 rpm, respectively. It was found that an out-of-phase condition for orbitally shaken bags, such has been previously described (5), also can occur with fluids that have properties similar to those found in plant cell suspensions. This is particularly evident in 20-L bags operating with a maximal working volume of 10 L at shaking frequencies in a range between 70 and 90 rpm.

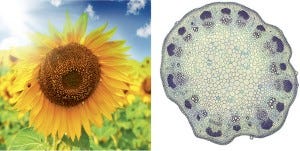

Sunflower in field and sunflower (Helianthus) stem cross section under a microscope

Cultivation experiments with Helianthus annuus plant cell suspensions (provided by the group of Prof. Dr. Thomas Bley from the Technical University Dresden, Germany) were conducted to verify scale-up from shake flasks to orbitally shaken bags. The successful scale-up of the plant cell suspension-based process is verified by almost identical cell growth behavior (packed cell volume, wet and dry cell concentration) and nutrient consumption (sugars, ammonia, nitrate) in shake flasks and orbitally shaken bags at scales of 2 L and 20 L. In fact, a peak-packed cell volume of approximately 75% was measured after 12 days.

These results reveal that orbitally shaken bags operated with the Multitron Cell incubator shaker and ShakerBag Option system represent an efficient and reliable option for plant cell suspension-based production processes. However, these findings demonstrate the importance of the preliminary engineering characterization to define appropriate operating conditions for cultivation processes.

References

1. Werner S. Innovative, Non-Stirred Bioreactors in Scales from Milliliters up to 1000 Liters for Suspension Cultures of Cells using Disposable Bags and Containers: A Swiss Contribution, Chim. Int. J. Chem.2010, 64: 819-823.

2. Eibl R, Lffelholz C, Eibl D. Animal Cell Biotechnology: Methods and Protocols Prtner R., Springer, Secaucus, NJ. 2013.

3.Eibl R, Werner S, Eibl D. Bag Bioreactor Based On Wave-Induced Motion: Characteristics and Applications Adv. Biochem. Eng. Biotechnol., 2010 (115): 55-87.

4. Eibl R, Werner S, Eibl D. Disposable Bioreactors for Plant Liquid Cultures at Litre Scale Eng. Life Sci. 2009(9): 156-164.

5. Werner S. An Approach for Scale-Up of Geometrically Dissimilar Orbitally Shaken Single-Use Bioreactors Chem. Ing. Tech. 2013(85): 112-118.

Sren Werner, Dipl. Ing., is senior scientific assistant at Zurich University of Applied Science School of Life Science and Facility Management, Institute of Biotechnology, Grental, CH-8820 Wdenswil, 41-58-934-5780; fax 41-58-935-5780; [email protected];

Johanna Olownia, Dipl. Ing., is product manager, cell culture, and Daniel Egger Dipl. Ing., MBE, is director of marketing at Infors AG, Rittergasse 27, CH-4103 Bottmingen, 41-61-425-7700; fax 41-61-425- 7701; [email protected]; www.infors-ht.com.

Dieter Eibl, Prof. Dr. Ing., is head of biochemical engineering and cell cultivation techniques at Zurich University of Applied Science.

You May Also Like