Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

August 11, 2016

Sponsored by Nordson Medical

During the fall of 2014, we received requests from a couple of large, single-use technology (SUT) system integrators asking whether we could develop a new tube clamp for their SUT assemblies and skids. There were several motivating factors behind these requests. As bioreactor skids became larger and larger (with thousand-liter and larger SUT containers), technicians had increasing difficulties assembling current clamps onto tubing. In some cases, technicians were lying on their stomachs and reaching under the bioreactors trying to install clamps. In other cases, they were standing on tall ladders or platforms reaching across the tank and container to access tubing.

During the fall of 2014, we received requests from a couple of large, single-use technology (SUT) system integrators asking whether we could develop a new tube clamp for their SUT assemblies and skids. There were several motivating factors behind these requests. As bioreactor skids became larger and larger (with thousand-liter and larger SUT containers), technicians had increasing difficulties assembling current clamps onto tubing. In some cases, technicians were lying on their stomachs and reaching under the bioreactors trying to install clamps. In other cases, they were standing on tall ladders or platforms reaching across the tank and container to access tubing.

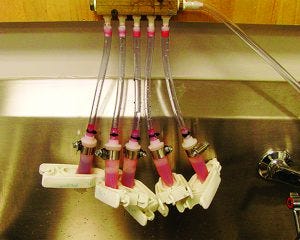

PharmaLok™ tube clamps during the long-duration pressure test

After discussing the technicians’ needs in more detail, we came away with a list of challenging requirements for a potential new product. The number-one desire was for a clamp that can be easily opened and closed using just one hand. This would simplify assembly while technicians reach into the center of skids to get to installation points. There were also numerous standard specifications, including the following:

The clamp should work with a wide range of common commercial-scale tubing dimensions from ½” up to 1” OD.

The clamp should shut off the product or process flow for both braided reinforced silicone and TPE tubing.

The clamp should be made of material that is commonly accepted among pharmaceutical system integrators and end users.

We then added a couple of additional requirements based upon our experience in the industry, including the following:

The clamp should be easy to use, replacing the repetitive motion involved with existing twist-to-close clamps.

The clamp should have a tamper-evident security feature to ensure that it remains in place during transportation. It should also maintain system integrity after system validation and pressure testing.

The clamp should not open during normal operating pressures.

The solution was to develop an easy-to-use, strong nylon clamp based upon Nordson MEDICAL’s PharmaLok™ platform. Our engineering team, lead by Toby Whitaker, developed testing protocols to make certain we met each of the requirements.

To address ease-of-use and one-handed operation, early prototypes were given to in-house staff and customers who participated in our Voice of the Customer (VOC) studies. Feedback was consistent across all genders, physical strength capabilities, and job descriptions that this product was effortless. Each participant was able to close the clamp with one hand.

To evaluate the shut-off feature, tubing was tested under 50 pounds of pressure for 30 minutes without any pressure drop using the traditional underwater bubble test. And as proof of concept, a long-duration send test was conducted at 25 psi for five days. Both pressure tests met all criteria and passed.

To demonstrate the strength of the clamp, an independent laboratory was engaged to perform high-pressure testing with water. Braided, reinforced silicone tubing was used because pressures went up to or above 200 psi. The PharmaLok™ tube clamp was never the failure point in any tests. A short video showing the collective results can be viewed at www.bioprocesscomponents.com/pharmalok-features.html.

To demonstrate the strength of the clamp, an independent laboratory was engaged to perform high-pressure testing with water. Braided, reinforced silicone tubing was used because pressures went up to or above 200 psi. The PharmaLok™ tube clamp was never the failure point in any tests. A short video showing the collective results can be viewed at www.bioprocesscomponents.com/pharmalok-features.html.

After considering the strong requirements from our industry partners and conducting specific tests, Nordson MEDICAL developed a glass-filled nylon tube clamp that is widely accepted across a broad range of companies using silicone and TPE tubing in their single-use applications.

Kenneth Davis is global market development manager, Biopharm; 805 West 71st Street, Loveland, CO, 80538; 1-970-226-8252; [email protected]; www.nordsonmedical.com.

You May Also Like