Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

Sponsored by Sartorius

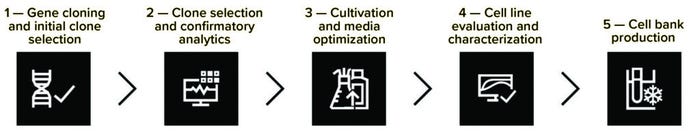

Cell-line development (CLD) involves screening thousands of clones to identify the most stable and productive candidate for an upstream manufacturing process (Figure 1). Such assessment requires considerable time and resources for preparation and execution of multiple cultivations and analytical assays. In March 2022, Lukas Klein and Dirk Müller (scientist and manager of media and process development, respectively, at Sartorius) delivered a BPI Ask the Expert webinar about integrating their company’s Ambr 15 Cell Culture bioreactor and Octet label-free biolayer interferometry (BLI) technology to accelerate CLD studies. The presenters highlighted applications for media screening and platform optimization.

Figure 1: Cell-line development (CLD) comprises several activities that require extensive time, resources, and analytical capabilities. The BPI Ask the Expert presentation summarized in this article focused on technologies for streamlining studies in steps two, three, and four of the CLD process, as outlined below.

Critical Capabilities

The Ambr 15 Cell Culture bioreactor comprises a workstation that can be installed in a biosafety cabinet, with single-use reactors and process-control software. Four culture stations operate up to 48 cultures in parallel, each with a working volume of 10–15 mL. A liquid-handling robot takes culture samples automatically for on- or off-line analysis of pH, metabolites, dissolved oxygen (DO), viable cell count (VCC), viable cell density (VCD), and other important parameters. The system provides standard controls for reactor temperature and stirring speed along with advanced controls for adjustment of each reaction vessel’s pH and DO levels.

Such controls, Klein explained, enable the microbioreactors to simulate the culture dynamics of benchtop systems, giving analysts insights into how clones might grow at laboratory scales. The system can perform batch, fed-batch, and even perfusion-mimic processes using adherent or suspension-adapted cells from mammalian and insect lines.

The Octet system performs label-free, real-time characterization of biomolecular interactions using BLI. Instrument sensors are coated in a ligand (e.g., protein A) to immobilize a desired analyte (e.g., a monoclonal antibody, MAb). That enables the system to measure its concentration and binding characteristics. The Octet system analyzes multiple samples per run and that its sensors can be regenerated for additional applications.

Combined with the instrument’s “dip and read” method, such capabilities enable high-throughput evaluation of CLD preparations. That could reduce analytical costs and experimental effort, Klein explained. In terms of labor costs, high-performance liquid chromatography (HPLC) and enzyme-linked immunosorbent assays (ELISAs) are, respectively, three and 15 times more expensive to run than an Octet workflow.

Case Studies

Media Screening: Müller explained that integrating the two technologies could streamline measurement of MAb titers during CLD. Both presenters provided examples of such integration. In one case, Sartorius scientists evaluated how two CHO-DG44 clones performed in five culture media, including formulations from vendors and variants developed internally. Because media screening can be time and labor intensive, Klein explained, the team needed a method that could generate data reliably, quickly, and at multiple time points — but with minimal labor and hands-on time. The team used the Ambr 15 Cell Culture bioreactor to cultivate clones in candidate media, programming the instrument to collect and analyze samples daily throughout the culture process. Those materials were transferred to the Octet platform for titer analysis.

Using those insights and results from other experiments, the team calculated the clones’ time-resolved cell-specific productivity (qP) in each medium. The first clone exhibited similar VCDs and stable qP values across most of the media, although the option with the lowest viability was excluded from further evaluation. For the second clone, two media generated high cell counts, whereas the other three candidates showed decreases in viability around day eight of the culture process. Ultimately, the integrated workflow guided media selection by highlighting potential limitations to titer and productivity.

Integrating the Ambr 15 Cell Culture bioreactor and Octet technology also accelerated screening activities considerably. Klein pointed out that operators usually need two hours to prepare 48 samples for HPLC analysis and three hours for 72 samples. Run times average 4.6 hours and 7 hours, respectively, and related buffer preparation takes three hours regardless of sample number. By contrast, operators need 30 minutes and 40 minutes to prepare 48 and 72 samples for Octet system analysis. Those values represent time savings of 75% and 80%. The Octet system can process up to 72 samples in 20–30 minutes — a time savings of 92–94%. The platform also eliminates need for buffer preparation, and consumables are reduced significantly.

Process Optimization: Optimizing a platform process for CLD entails extensive screening of multiple clones and conditions. Klein described how his team used the Ambr 15 Cell Culture bioreactor and Octet technology to streamline process optimization.

The team needed to establish a new process with a focus on high qP as the most important target value. Parameters with significant bearing on qP scalability included stirring speed, ballast gassing rate, and starting volume. Thus, Klein and his colleagues focused on optimizing those conditions. Modde software was used to define a design-of-experiments (DoE) workspace for those parameters. The program identified 12 conditions for testing, and clones were cultured in duplicates accordingly in an Ambr 15 system, which drew and analyzed culture samples automatically. Then, the team transferred those materials to the Octet platform for titer determination. All data, including subsequent qP calculations, were fed back into the Modde program to identify the optimal conditions.

The software showed that increases to starting volume tended to diminish qP. Meanwhile, increases in stirring speed had positive impacts on qP up to a certain value, after which productivity diminished. Multiparameter analyses revealed that increasing ballast gassing rates improved qP values when stirring speeds were kept low, but those gains diminished and then reversed as stirring speed increased. The team also observed that cell viability diminished slightly at high stirring and ballast gassing rates, yet DO levels showed no corresponding declines. Thus, shear stress would be an important consideration for the clone in question, whereas oxygen limitation would not be a problem. Balancing all of those concerns, the team decided to perform low-volume cultures at moderately high stirring speeds and with minimal ballast gassing.

Significant Gains: Müller reiterated that leveraging the Ambr 15 Cell Culture bioreactor’s automation capability with the high-throughput analyses of the Octet platform could streamline execution of CLD studies significantly. Adding Modde software to a workflow could help to optimize microculture parameters further.

Questions and Answers

Can the Ambr 15 Cell Culture bioreactor serve as a good scale-down model for process characterization? It can serve that purpose, although it is used primarily to screen and optimize process parameters. Sartorius recommends using the Ambr 250 cell culture system for process characterization because it features advanced process controls and performs in ways that represent how cultures will perform at pilot scales.

What advantages come with the Octet system’s sensor-regeneration capability? Sartorius leverages that feature to process 72 samples simultaneously. The regeneration capability also diminishes analytical and consumables costs significantly.

Find More Online

Watch the full presentation at https://bioprocessintl.com/sponsored-content/improve-your-cell-line-development-workflows-with-analytical-tools.

Brian Gazaille, PhD, is associate editor at BioProcess International, part of Informa Connect; [email protected].

You May Also Like