Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

Sponsored by Sartorius

An estimated 300 million people worldwide live with rare diseases, and over 70% of such disorders are caused by genetic mutations (1, 2). Cell and gene therapies offer hope and potential cures for many previously untreatable diseases. Accordingly, the global gene therapy market is expected to be worth USD 5.02 billion by 2028, a significant growth from USD 1.46 billion in 2020 (3).

Manufacturing gene therapies will be a key challenge over the next two decades. But just a few decades ago, the industry was in a similar position for recombinant protein production. The lessons learned from generating high-performing Chinese hamster ovary (CHO) cell lines can be used to accelerate progress toward a gene therapy process platform.

Viral vectors are ideal vehicles for gene transfer because of their high transduction efficiency, effective gene delivery, and stable gene expression. Immortalized human embryonic kidney (HEK) 293 cells are the optimal host cells for virus production. Together, HEK293 cells and viral vectors represent the basis of many new biologic modalities.

As demand for viral vectors has continued to rise, many gene therapy developers struggle to scale up their production capacity sufficiently. The traditional scale-up path taken by small-molecule and/or recombinant-protein manufacturers does not translate to new modalities and processes. Moreover, viral-vector manufacturing is a newer field, with fewer years of process optimization and experience to rely on.

Thankfully, the gene therapy field is evolving quickly. Key cell-culture advances can benefit therapeutic development at multiple stages throughout a manufacturing pipeline. Herein, we discuss how such developments can help manufacturers maximize the benefits of HEK cell lines by resolving past challenges and unlocking their full potential for performance and growth.

Supporting the Unique Characteristics of HEK Cells

Superior Viral-Vector Production: HEK293 cell lines play a foundational role in the development of many major gene therapy classes. They are recognized as excellent hosts for adenoassociated virus (AAV) production in particular because the cells already carry adenovirus sequences (E1A and E1B-55k), which provide helper functions (4). Additionally, the human origin of HEK cells can lower the risk of immunogenic side effects when administered to patients. Although viral-vector production processes have been tested in more well-established CHO cells to mitigate regulatory issues, HEK cell lines remain the best hosts in terms of both titer and product quality.

Transition to Serum-Free Suspension Culture: Traditional HEK cell-line processes are carried out in adherent cultures. To make bioprocesses scalable and fulfill current demand, cell lines ideally should be transitioned to suspension culture (5). That transition offers benefits beyond scalability; adherent processes typically rely on the use of animal-derived, protein-rich serum, which introduces confounding variables into a final product. Serum culture is associated with a risk of transmissible spongiform encephalopathy (TSE), higher costs, and ethical concerns. Additionally, poorly defined serum components contribute to batch variability, creating significant regulatory obstacles for products destined for human use. Serum-free suspension culture promotes greater robustness and process control.

Transient Transfection: Recombinant protein production usually is carried out by stable transfection of CHO cell lines in a well-defined process. By contrast, viral-vector production in HEK cells relies on transient transfection, which is more complex and variable, introducing more challenges into a manufacturing process.

Cellular Characteristics: HEK cells also have distinct membrane characteristics. The unique lipid composition and fluidity of their membranes make them straightforward to transfect and suitable for transient transfection, but they also are sensitive to shear stress and prone to aggregation. Optimized media formulations with a careful balance of well-defined components help minimize the effects of shear stress while supporting transient transfection. Building a better understanding of HEK cell metabolism and its impact on AAV production will support more efficient and high-yielding gene therapy production processes.

Finding the Right Partner

The top priorities for selecting a media provider are performance, supply security, and capacity. A media provider that acts as a partner rather than a supplier can be an excellent way to navigate your media journey.

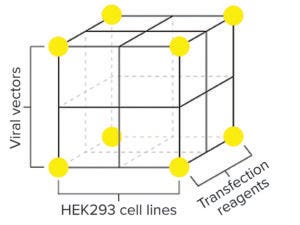

Figure 1: Interactions of a number of viral‑vector process parameters unlock previously concealed insights about HEK media performance.

Performance: Production processes for gene therapy have yet to reach maturity. Product knowledge, testing, and optimization help prevent some common pitfalls faced by gene therapy developers, including low titers, poor process efficiency, and scale-up difficulties. Fully developed and tested media are more likely to generate good results. It is important that your supplier has performed sufficient characterization work within the HEK media design space, including testing across a number of cell lines, transfection reagents, process parameters, AAV serotypes, and culture conditions. Such work facilitates, accelerates, and increases the chance of selecting high-performing media, relieving some of the pressures of upstream process development. For example, Sartorius’s new media portfolio already has been tested and verified using a panel of commercially available HEK cell lines and diverse process parameters (Figure 1). The HEK media panel addresses the unique characteristics of different cell lines and process requirements, simplifying users’ search for the optimal media.

Assurance of Quality Supply: Assurance of supply has been a crucial business driver for companies across all industries, with the COVID-19 pandemic highlighting weaknesses in global supply chains (6). Media suppliers must have a resilient supply network with dual sourcing, redundancies, and multiple production sites to ensure reasonable lead times and rapid response to fluctuations. As gene therapy demand continues to rise, time-to-clinic and time-to-market will become even more critical than they are now.

Media suppliers also should demonstrate consistency and high quality of their raw materials. Those materials will contain contaminants, e.g., trace elements such as manganese, iron, zinc, and copper, which can compromise both cell culture processes and product quality. Careful raw material characterization and qualification procedures must verify that media suppliers source the highest-quality raw materials in compliance with compendial monographs.

It is vital to understand the raw materials that enter your manufacturing process and how trace elements will affect it. To minimize such variability, Sartorius has an extensive raw-material inspection program in which critical quality attributes of every lot of each material are tested using state-of-the-art analytical methods.

Capacity: As the demand for gene therapies continues to grow, progress is hampered by the lack of well-defined, scalable viral-vector production processes. Upstream processing efficiencies are likely to improve as our understanding of viral-vector production grows and processes mature. Such factors will have a dynamic effect on your media needs. Efficient manufacturing systems with cell-line, media, and process parameters working in harmony are needed to achieve high titers in reduced media volumes.

Although process development is likely to take place on a relatively small scale, you must consider future operations when designing cell culture processes and selecting a media product and provider. What volumes are expected at a commercial scale? Does your supplier have the capacity to meet those quantities currently? Is it undergoing capacity expansions to meet future scale-up needs? Choosing a reliable partner that shares your vision for the future of your gene therapy production process is essential to maintaining a consistent supply during scale-up.

Lessening Barriers to Adoption

Knowledge of HEK cell lines and AAV production is not as complete as our understanding of CHO metabolic and proteomic profiles. However, insights gained from optimization of CHO processes are contributing to a fast accumulation of expertise and a quickly advancing field. New products such as specialized HEK293 media and the progress toward creating gene therapy process platforms also significantly lessen barriers to adoption — especially when paired with scientific support and a robust manufacturing network from a reliable partner with expertise throughout the media pipeline.

References

1 Nguengang WS, et al. Estimating Cumulative Point Prevalence of Rare Diseases: Analysis of the Orphanet Database. Eur. J. Hum. Genet. 28(2) 2020:165–173.

2 New Scientific Paper Confirms 300 Million People Living with a Rare Disease Worldwide. Rare Diseases International: 15 October 2019; https://www.rarediseasesinternational.org/new-scientific-paper-confirms-300-million-people-living-with-a-rare-disease-worldwide.

3 Gene Therapy Market Size, Share. Global Industry Growth Report 2028. Polaris Market Research: 2021; https://www.polarismarketresearch.com/industry-analysis/gene-therapy-market.

4 Tan E, et al. HEK293 Cell Line As a Platform to Produce Recombinant Proteins and Viral Vectors. Front. Bioeng. Biotechnol. 9, 2021: 796991; https://doi.org/10.3389%2Ffbioe.2021.796991.

5 Cheung G. Adaptation of Mammalian Cell Lines to Serum-Free Suspension Culture. Xell: Bielefeld, Germany, 15 October 2020; https://www.xell.ag/adaptation-cell-lines-suspension/technical-notes.

6 Mirtsch M, et al. Quality Assurance in Supply Chains During The COVID-19 Pandemic: Empirical Evidence on Organisational Resilience of Conformity Assessment Bodies. Total Qual. Manag. Bus. Excell. June 2022; https://www.tandfonline.com/doi/full/10.1080/14783363.2022.2078189.

Catherine Buchere is a product manager in virus-based therapeutics at Sartorius; [email protected]. Sandra Klausing is a manager of media and process development at Sartorius; [email protected].

Learn more about Sartorius’s HEK293 media (www.sartorius.com/hek293-media) or scan to sign up for your free HEK293 media kit.

You May Also Like