Using Optical Sensors for Bioprocess Monitoring: A Measurement Technique for Bioprocessors

March 14, 2016

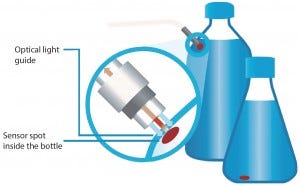

Figure 1: Contact-free measurement with chemical optical sensors

Over the past decade, the application of chemical optical sensors for bioprocess monitoring has gradually taken roots. Constant further development of this measurement technology and the possibility to manufacture such sensors in various designs (even for single-use applications) have led to new state-of-the-art devices for the biotechnology sector. Chemical optical sensors enable in situ, real-time monitoring of important culture parameters without sampling and therefore without disturbing a culture. Implementing this technology can decrease workloads and deepen knowledge about bioprocesses.

In many culture environments and vessel formats, application of electrodes would be very cumbersome or impossible. Too many electrodes disturb the flow pattern of some vessels (especially at small scale) or are simply difficult to integrate because of a lack of space. Such difficulties can be overcome by miniaturized chemical optical sensors. Their small size allows application in small-scale stirred bioreactors without disturbing culture environments or liquid flow. In addition, these sensors require no reference cells and consume no analyte during measurement.

The greatest advantage of using optical sensors is that they can be applied for remote sensing. The sensing component (the actual sensor) and the electro-optical components for sensor read-out (the transmitter) do not have to be in direct contact. In this way, measurements can be performed through transparent or even slightly colored vessel walls and optical windows. Whereas a sensor is attached to the inner wall of a container, its signal is recorded from the outside with the respective meter. That reduces the risk of contamination in culture monitoring to a minimum. And without sampling measurement, errors by oxygen ingress or CO2 outgassing can be prevented.

These sensors are useful in other applications as well. Because of the many different sensor designs (from smallest sensor spots to robust dipping probes), they can be implemented in bioprocess monitoring from milliliter scales to those of several liters. Optical sensors can monitor culture parameters O2, pH, and CO2 online throughout an entire culture period. That allows timely intervention if limiting culture conditions develop and provides detailed information about the metabolic status of cells inside culture vessels (e.g., microtiter plates, cultivation tubes, and shake flasks) up to liter-scale bioreactors.

The Measurement Principle

The term fiber chemical optical may sound a little complicated, but the measurement principle can be easily explained. At the core of this technique is the indicator: a fluorescent analyte-sensitive dye. That dye is embedded in a polymer matrix so that it does not leach into a culture medium or sample. The indicator is excited with light of a certain wavelength and emits fluorescence in response. According to the amount of analyte molecules present, dye changes its fluorescence signal. That change in signal is measured by a respective electro-optical reading device and can be translated into concentration values. Optical fibers are used to transfer excitation light to the indicator dye and sensor response back to the reading device (Figure 1). The indicator inside its polymer matrix can be coated on a carrier material or directly onto the distal end of an optical fiber so that different sensor designs can be achieved.

Figure 2: (A) chemical optical sensor spots for oxygen measurement (SP-PSt3 units), (B) disposable and reusable shake flask and multidish with integrated sensors (SFS and OxoDish units), (C) dipping probes (OIM and DP units), and (D) needle-type housed microsensor (NTH unit)

The Right Sensor for Each Application

The most versatile version of chemical optical sensors are so-called sensor spots. Here, a polymer matrix with an indicator dye is coated onto a small round foil layer, usually with a diameter of 5 mm (Figure 2A). Such sensor spots for either oxygen, pH, or carbon dioxide can be glued to the inner surface of a transparent culture vessel, where they come into contact with a culture medium. The data are then read from the outside with the respective reader. Contact-free readings also can be applied for measurements inside perfusion systems because flow-through cells with integrated sensors also are available.

Separation of sensing component and reading device makes optical sensors ideal for single-use applications. Disposable culture vessels with installed single-use sensor spots are commercially available (Figure 2B). Single-use optical sensors are applicable especially for cell cultures in polymer bags. The sensors come irradiated and already integrated into the bags, so there is no need for probe sterilization or integration.

Fiber-optical dipping probes have similar design to the sensor spots. A sensor is attached to the distal end of a steel tube that encloses the optical fiber (Figure 2C). These probes are available with exchangeable sensor caps, with port adapters for bioreactors, and in multiple autoclavable versions.

In microsensor designs, the sensor dye is coated to the end of optical fibers (with tip sizes as small as 50 µm in diameter), which are then connected to a reading device. These sensors are available as bare fiber microsensors, which are ideal for customized applications. And needle-type housed microsensors are integrated in a syringe cannula (Figure 2D). Because the optical fiber is thin, it is susceptible to breaking; but integrated in the steel cannula, it can safely be pierced through septum rubber or packaging material. Although the devices are not applicable for remote sensing like the sensor spots, the fiber optical designs are minimally invasive and provide high spatial resolutions and fast response times. These sensors can be applied with micromanipulators for precise localization of the sensor tip inside the sample or for profiling.

Figure 3: (A) Microx 4 trace, portable oxygen meter for read out of chemical optical sensors, (B) SFR shake flask reader for parallel read out of up to nine culture vessels with integrated sensors, (C) SDR SensorDish reader here used with a 24–deep-well plate with integrated sensors

Meters, Readers and Culture Vessels

Optical sensors can be combined with different types of meters and readers. Portable meters can be used with spots, dipping probes, and microsensors for laboratory and research applications (Figure 3A). Other reader units can be installed directly inside shaking incubators or come as separate multianalysis and control devices from benchtop format to industrial scale. Such reader units are designed especially for bioprocess development and control.

Multichannel readers for oxygen and pH monitoring inside multiwell (six- or 24-well formats) or microtiterplates (48- or 96-well formats) are ideal for small-scale, high-throughput screenings (Figure 3C). With this unit, culture control in even such small volumes can be achieved.

A special shake-flask reader enables culture monitoring for up to nine flasks simultaneously from 250 mL to 2 L volume. Disposable and reusable flasks with integrated sensors are available. Those flask readers also can be used for oxygen and pH monitoring in culture tubes or T-flasks (Figure 3B). Special workstations make it possible to control multiple stirred bioreactors of 100–250-mL volumes. Designed connection ports allow easy gas, liquid, and sensors information transfer.

For application of single-use sensors in cell culture bags, sensor ports are used to attach the optical fiber from the outside to a bag. A special oxygen and pH meter then translates the signal of a chemical optical sensors inside the bag so it can be transferred to a conventional controller.

The Sensor Solution

Use of electrodes for determining important culture parameters and for culture control is still the most common practice in research and manufacturing. In the past, culture monitoring and control applications often were neglected because they were conducted in formats in which electrodes were not applicable. Chemical optical sensors now offer a measurement solution for online data acquisition. They can be used in a wide range of applications. Compared with sampling or end-point analyses of bioprocesses, online monitoring with chemical optical sensors is a major step toward more economical work flows while allowing for more control. For bioprocess development operations and upscaling processes, information about metabolic statuses and the possibility of simultaneous monitoring of various cultures are great advantages.

Gernot T. John is the director of marketing and innovation at PreSens Precision Sensing GmbH, Regensburg, Germany; [email protected].

You May Also Like