Global Marketplace May 2009

May 1, 2009

Depth-Filtration Platform

Product: Stax disposable depth filter platform

Application: Downstream processing

Features: Simplicity, intuitive operation, safety, and speed improve the efficiency of depth filtration processes. A stack of single-use depth filter capsules are configured in an ergonomic, vertical design to enable a single operator to load, operate, and unload within a reduced footprint. Single-use capsules eliminate the need for cleaning and associated validation. Interlocking modules are interchangeable and scalable.

Contact Pall Life Sciences

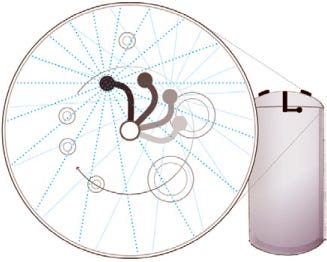

Clean-in-Place (CIP)

Product: RotaCIP cleaning equipment

Applications: Bioreactor cleaning in place

Features: Static spray balls create spray shadows that make for insufficient cleaning and are potential sources of contamination. Bioengineering’s RotaCIP lance with spray balls eliminates the problem with dynamic motion. Rotation of the lance around its axis is driven by the force of the CIP fluid. Plain bearings ensure low maintenance and safe performance. Modular, custom-made construction ensures good cleaning. Sensor monitoring is optional.

Contact Bioengineering AG

Prefilled Syringes

Service: Bubble-Free Filling process

Application: Fill and finish

Features: Bubble elimination in a prefilled syringe offers many advantages. After validated studies, an innovative, patented method is available to fill syringes without the air bubble. The key advantages of Hyaluron’s prefilled syringes are safety in administration, ease of use, reduced risk of contamination, less waste of costly or scarce active pharmaceutical ingredients (APIs), improved dosing accuracy, and improved sterility assurance. The Bubble-Free Filling process eliminates stopper movement when a syringe is exposed to reduced atmospheric pressure.

Contact Hyaluron

Contract Manufacturing

Fill–Finish Services

Service: Ultrahigh-speed packaging

Applications: Prefilled syringes of sterile liquid dosage forms

Features: A new packaging facility went online in January 2009, IDT Biologika’s response to increased demand for the company’s fully integrated services ranging from formulation development and clinical manufacturing through large-scale commercial production, packaging, quality control, and logistics. The highly automated facility can package up to 30,000,000 syringes/year. This packaging line represents a €3,500,000 investment and took 14 months to complete, test, and achieve regulatory compliance.

Contact IDT Biologika GmbH

Antibody Analysis

Product: Anti-Human IgG Fc Capture (AHC) biosensor

Applications: Characterization and screening of human IgG antibodies

Features: For use on the ForteBio Octet instrumentation platform, this biosensor enables kinetic profiling of human IgGs or other Fc-containing proteins against analyte in a microplate. The surface can also be used for expanding the variables measurable by ligand-inhibition assays, such as affinity, association/disassociation rates, and blocking/unblocking of analytes. These biosensors are configured in a standard 96-well format with a proprietary biocompatible matrix that is uniform, nondenaturing, and has minimal nonspecific binding.

Contact ForteBio, Inc.

Cell Line Development

Service: One-Step cell line construction

Applications: Mammalian cell culture

Features: Lonza scientists have developed a cell line construction process that delivers 5.5 g/L of CGMP material in 14 months from the receipt of a DNA sequence, test material from uncloned cell lines in 11 months, and proof-of-concept material in four months. The customer-tailored process uses chemically defined components of nonanimal origin and includes stability testing, stringent selection for high-yielding cell lines, procedures and data supporting monoclonality, and regulatory support. With the company’s proprietary GS gene expression system, the One-Step program can be further tailored to suit project and timeline requirements.

Contact Lonza Group Ltd.

Fluid Management Solutions

Product: FlexStation containers

Applications: Transport and shipping

Features: Part of the One-Touch single-use systems family, these rigid containers complement Meissner’s single-use biocontainers and fluid path assemblies for intrafacility transportation and interfacility shipping and fluid management. They come in standard sizes of 50 L, 100 L, 200 L, 500 L, and 1,000 L to fit TepoFlex 3D biocontainers. They are reusable and collapsible for storage/handling when not in use.

Contact Meissner Filtration Products, Inc.

Cell Culture, Fermentation

Product: BioFlo/CelliGen 115 fermentor–bioreactor (1.3–14 L)

Application: Benchtop, autoclavable fermentation and cell culture

Features: This 1.3- to 1.4-L fermentor–bioreactor is a versatile, entry-level system that takes the complexity out of equipment selection, set-up, and operation. It can be unpacked and set up in about half an hour. Its integrated control station includes a color touch-screen interface, pumps, configurable gas flow controllers, pH/DO measurement, and foam/level controllers. No external PC is needed. Intuitive control screens are capable of regulating up to three independent systems. Numerous options provide flexibility for a range of applications.

Contact New Brunswick Scientific

www.nbsc.com/B5F (ASM booth #525)

Aseptic Processing

Literature: Flexicon Filling Range catalog

Applications: Purification, fill and finish

Features: This catalog is a guide to the complete range of Flexicon peristaltic equipment from Watson-Marlowe. The technology offers a contamination-free, single-use flowpath to simplify cleaning/validation and enhance the integrity of high-purity upstream processes, purification, and fill–finish applications. Every pump listed here is an inherently metering pump with 99.5% repeatability. Many include integral digital drives. They accommodate flow rates of 0.1 µL to 350 gallons per minute and withstand pressures ≤232 psi. They can also run dry indefinitely without damage and are reversible for backflushing lines.

Contact Watson-Marlowe Pumps Group

Upstream Process Control

Product: Integration of ARS-M online autosamplers with the DASGIP parallel bioreactor system

Applications: Bioreactor monitoring and control

Features: DASGIP and Groton Biosystems are collaborating to offer a complete closed-loop solution for online bioreactor monitoring. The combined system provides multivessel autosampler support, online data integration, user-defined feedback control strategies, and real-time nutrient monitoring and control. Maintain optimum nutrient levels for up to eight bioreactors. A joint application note outlining the combined unit is available online.

Contact Groton Biosystems

www.grotonbiosystems.com and DASGIP AG www.dasgip.de

Oxygen Monitoring

Product: Visiferm DO sensor

Applications: Microbial fermentation and animal cell culture

Features: This optical dissolved oxygen sensor reduces measurement times with improved ease of use over classical Clark cell technology. Symmetrical, heat-resistant, dual-channel optics and a measurement amplifier are all self-contained in a standard 12-mm format. Polarization that takes up to eight hours with traditional sensors is complete in ≥15 minutes with this product. Designed with just one replacement part, the Visiferm sensor is flow independent and invulnerable to interference from acidic gases. Calibration is simplified because data are stored in the sensor.

Contact Hamilton Company

For Serum-Free Culture

Product: CellPrime rAlbumin AF-G supplement

Applications: Commercial and research-scale serum-free mammalian cell culture

Features: Manufactured by Novozymes, this recombinant human serum albumin product is specifically engineered to provide and animal-free alternative to serum-derived human or bovine albumin supplements. It offers all the benefits of native albumin without the regulatory challenges associated with animal-derived sources. Move beyond chemically defined media without compromising performance or safety.

Contact Millipore Corporation

You May Also Like