Global Marketplace September 2009

September 1, 2009

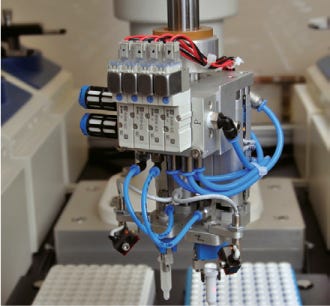

Automated Chromatography

Product: Tecan Freedom EVO liquid handling workstation

Applications: Resin and condition screening, bioreactor monitoring, sample preparation

Features: Atoll RoboColumns miniaturized columns are prepacked with a resin of choice in a 96-array SBS format and integrated on a liquid handling robotic workstation. Eight columns are processed together for highly reproducible chromatographic separations. Fraction volumes ≥25 µL can be collected, providing sufficient data points to construct a chromatogram. The entire process can be automated, from buffer preparation and column equilibration to column regeneration, providing results quickly with minimal sample consumption.

Contact: Tecan Group Ltd. www.tecan.com/parallel

Shake-Flask Reader

Product: SFR shake-flask reader

Application: Small-scale microbial cultivation and cell culture

Features: The shake-flask reader measures oxygen and pH in up to nine shake flasks simultaneously to ensure optimal growth conditions. This wireless system monitors on-line and noninvasively. Its software visualizes oxygen and pH in real-time during an entire cultivation. Monitoring helps to optimize cultivation parameters systematically and provides reliable comparison of screening results. With ready-to-use, calibration-free shake flasks, the reader is compatible with standard shakers. Flasks are available in a number of sizes.

Contact: PreSens Precision Sensing www.presens.de/SFR

High-Throughput Analysis

Product: Advanced 20G high-throughput osmometer

Application: Cell culture process development and optimization

Features: The Advanced 20G high-throughput osmometer combines state-of-the art osmometry technology and robotics within a parallel sample-processing scheme. With this system, samples can be analyzed in a 96-well format within 35 minutes, and it offers the same accuracy as stand-alone osmometers. The 20G system has been applied to support osmolality testing in even the most demanding cell culture process development schemes in the biopharmaceutical industry.

Contact: Advanced Instruments Inc.www.aicompanies.com

Harvest/Clarification

Product: CEPA high-speed, continous-flow centrifuges

Applications: Rapid separations of liquid– liquid or liquid–solid mixtures

Features: New Brunswick Scientific’s CEPA centrifuges come in bench-through production-scale, high-speed models with a maximum throughput of 3,000 L/h. Typically used for harvesting biomass from fermentation runs, as well as clarifying process liquids, separating liquid products, bioremediation, and more, these centrifuges can process many times their bowl volume with a flow-through method that retains solids and collects liquid components. Without costly disposable membranes they are faster than filtration, with no midrun degradation due to clogged filters.

Contact New Brunswick Scientific www.nbsc.com/bin

Water for Injection

Service: Prefilled WFI syringes

Application: Reconsituting lyophilized products for injection

Features: Vetter’s water-for-injection syringes combine the company’s expertise in providing aseptically prefilled solutions with the quality of West Pharmaceutical’s primary packaging components. Vetter works with a client’s team to provide a turn-key manufacturing solution that includes validation and stability data for all WFI applications. Stability data complies with US, Japanese, and European pharmacopoeial and ICH guidelines; registration documents are readily available in CTD format for Europe, Japan, and numerous other countries. A Drug Master File is also provided for US submissions.

Contact: Vetter Pharma International www.vetter-pharma.com

Plasmid Purification

Product: CIM HiP2 Plasmid Process Pack process development tool

Applications: Industrial plasmid DNA purification process development and production of pDNA for laboratory use

Features: This pack contains two 1-mL CIM monolithic columns (DEAE, High Ligand Density C4) and a complete and easy-to-follow pDNA purification method. Monoliths produce CGMP-quality pDNA; yields of >80%; and reduction of chromatographic steps, purification times, and buffer consumption in all stages of process development and production. The method is flexible and allows for adoption in full or in part.

Contact: BIA Separations GmbH www.monoliths.com

You May Also Like