BiomX has announced plans to construct a clinical facility in Israel capable of making host bacteria in a 20-40 liter bioreactor for the production of bacteriophages.

The facility in Ness Ziona, Israel will primarily be used to manufacture clinical supply of BiomX’s candidate BX002 as it enters the clinic as a potential treatment for inflammatory bowel disease (IBD).

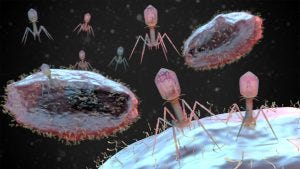

The candidate is a phage; a virus that infects and replicates within a bacterium. Such therapies were used extensively in the Soviet Union as an alternative to antibiotics, but there has been a surge of interest in phages due to the rise of multi-drug resistant bacteria. For example, AmpliPhi and C3J, which merged earlier this year, have GMP plants in Slovenia and California.

Image: iStock/Marcin Klapczynski

“The plant is planned to support manufacture and release of material for Phase 1 and Phase 2 clinical trials,” a BiomX spokesperson told this publication. Once complete, about 25 manufacturing campaigns will be performed per year, though the plant could be expanded for future needs.

“The process includes culture of producer host bacteria in a 20-40 liter bioreactor and infection with the specific bacteriophage to be produced.

“After infection, the resulting bacterial lysate containing the bacteriophage is harvested and purified by liquid chromatography and tangential flow filtration (TFF). The obtained purified bacteriophage is filtered in an aseptic environment and constitutes the drug substance (DS). Each bacteriophage in the cocktail is processed in a similar manner and compounded at the stage of drug product.”

While the investment level has not been disclosed, the firm told us the current manufacturing team includes 10 employees supporting the upstream production, downstream purification and associated analytical (QC) activities for the intended clinical trial with BX002, and will grow moving forward.

There are several contract development and manufacturing organizations (CDMOs) that offer GMP phage manufacturing services but BiomX chose to construct its own for competitive and flexibility reasons.

“Owning and operating our own manufacturing facility provides us with a competitive advantage by allowing close oversight and control, thus enhancing our ability to meet our manufacturing needs in a timely manner. Moreover, the ability to quickly and flexibly respond to new pre-clinical and clinical data allows us to modify our phage cocktails accordingly.”

CORRECTION: The original article stated CDMO Cobra Biologics offered phage manufacturing services but this is no longer the case.

About the Author

You May Also Like

schedl_b_and_w.jpg?width=100&auto=webp&quality=80&disable=upscale)

schedl_b_and_w.jpg?width=400&auto=webp&quality=80&disable=upscale)