Recovery and Purification - BioProcess International Conference & Exposition 2015

September 18, 2015

BIOGEN IDEC (WWW.BIOGENIDEC.CO.UK)

During the past decade, biomanufacturers have faced increasing bottlenecks, process times, and operation costs in their downstream processing. That has led many companies to reevaluate their traditional methods and technologies and consider replacing or supplementing them with strategies for reducing the number of purification steps and leveraging more efficient, less expensive, and well- understood approaches.

Some strategies to enhance efficiency have focused on optimizing recovery and initial clarification processes, especially when removing host-cell proteins (HCPs). Although HCPs are an essential component of the growth and survival of normal cellular processes, the presence of residual HCPs can pose safety risks for drug products. Part of the problem manufacturers are having with clearing HCPs is the difficulty in identifying them. This year’s BPI Conference and Exhibition will feature some presentations dedicated to handling that task, including the use of mass spectrometry techniques, as discussed below.

Other downstream efficiency strategies have focused on nonchromatographic protein purification approaches, non– protein A steps, and high-throughput process development. However, the challenges of each continue to be scalability and process understanding.

Other discussions in recovery and purification focus on familiar concepts such as continuous processing, particularly in harmonizing upstream and downstream operations. Complicating this task is the increasing number of high cell-density materials coming from advanced upstream process systems. In general, however, the bioindustry is still in the “evaluation phase”: weighing the potential benefits offered by continuous downstream operations compared with traditional (and well-known) batch-mode processing.

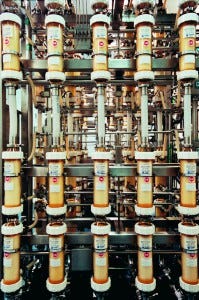

The industry also continues to discuss the expanded implementation of single-use systems and technologies in downstream processing. Biomanufacturers are keeping a close eye on single-use chromatographies and the concept of a “totally single-use” facility, all while discovering how these advancements fit into the need for greater process understanding and how that understanding ultimately connects with the quality of finished products.

BioProcess International spoke with selected conference presenters who will address some of the major issues in recovery and purification. Please visit the website listed at the end of the article for their complete podcasts.

Lin Zang (Biogen)

Lin Zang, PhD (senior scientist of analytical development at Biogen) will be joining us for the “Advances in Host-Cell Protein Identification, Understanding, and Clearance” session on Wednesday afternoon, 28 October 2015. Her presentation is titled “Characterization of Host-Cell Proteins Using Mass Spectrometry Enables Effective Purification Optimization.”

Abstract: Host-cell proteins are in-process impurities of that pose challenges to development of an optimized downstream purification process. Identification and quantitation of HCPs using mass spectrometry (MS) have enhanced understanding in terms of their physical properties and potential interaction with biopharmaceutical proteins, thereby providing valuable information for optimization of purification processes.

Would you briefly describe the MS– based workflow that you’ll be presenting for HCP identification? The MS–based workflow for HCP identification mainly includes a nano liquid chromatography (LC) separation followed by an MS sequencing of HCP peptides. It’s a typical proteomics workflow for protein identification. This has been presented and applied by many biotechnology companies for HCP identification.

How does a deeper understanding of HCP characteristics help in optimizing your downstream process? HCPs as process-related impurities could be very diverse in their properties, especially biological functions. Some HCPs have enzymatic functions associated with them that could potentially affect the efficacy and stability of a drug.

So it is important to identify and understand the HCPs that are present in biopharmaceuticals and to have a more effective risk assessment of those HCPs. It is useful to know their identities and their potential biological functions as well as the levels of individual HCPs present in biopharmaceuticals to have a comprehensive risk assessment of this important process-related impurity.

One specific example comes from an article that Biogen published about a trace level of HCP that was identified and copurified with an antibody biopharmaceutical. When the antibody was put into stability testing, this HCP had such a protease function that it actually affected the stability of the drug. That is important information for downstream process optimization. Eventually the process had to be changed to lower the level of that enzyme impurity as part of the HCP. That is one good example of making necessary process changes related to an HCP to meet a certain quality profile of a biopharmaceutical.

What other tools or software are used in downstream process development in regard to HCPs and process-related impurities? For HCPs, bioassays are a common tool that people use. When certain interesting HCPs or problematic HCPs are identified by liquid chromatography (LC)–MS workflow, there could be a targeted bioassay or ELISA [enzyme linked immunosorbent assay] developed for target monitoring of those problematic HCPs. For analysis of other process- related impurities (such as residual DNA or residual protein A) in antibody-type biopharmaceuticals, people typically use an ELISA method.

What else from your talk would downstream processing scientists find interesting? The work will present is related to the application of the LC– MS workflow for identification of HCPs present in antibody programs. There will be some discussion around the protein and HCP interaction that potentially can cause a challenge in purification processes.

Aside from speaking, why are you attending the BPI Conference? I’m interested in learning new technologies and innovations that the biotechnology industry is bringing up this year. I think it is a good place to be to find out about those innovations. So I’m excited to attend this conference this year.

>> Listen to the full interview

Min Zhu (MediMMune LLC)

Min Zhu, PhD (principal scientist in purification process sciences at MedImmune LLC) will also be joining us for the “Advances in Host-Cell Protein Identification, Understanding, and Clearance” session on Wednesday afternoon, 28 October 2015. Her presentation is titled “A Novel Approach to Monitor Clearance of Host-Cell Proteins Associated with Monoclonal Antibodies” (MAbs).

Abstract: This presentation will cover the development of a novel approach to profile HCP–MAb interactions and identification of HCPs copurified with MAb during protein A affinity chromatography by MS as well as evaluation of approaches breaking HCP–MAb interactions. Monitoring HCP levels will be discussed as well as species rational design to maximize removal of HCPs and development of targeted control strategies toward a more scientific paradigm for HCP control.

Would you briefly describe the novel approach for HCP–MAb interaction you’ll be presenting? This presentation is for people who are interested in knowing the identity of HCPs, especially those that copurify with MAb using a typical MAbs platform purification process. The big challenge encountered by many people is that the amount of the HCPs in a purified product is so low that the interference from a MAb is significant and prevents any technology from being used to identify the those HCPs from a highly purified product.

The novelty of our approach is that we immobilize HCPs to a MAb column. We flush through a condition medium (some people call it “cell culture fluid”) from the culture without MAb. By doing it this way, you can specifically capture the HCPs that interact with MAb without interfering with the MAbs. This approach is coupled with MS analysis through a sequence database search. That helps us to understand what HCP has been bound to the MAb. From there, we can effectively develop a process that breaks HCP–MAb interactions. This technique can assist in process development effectively.

What types of approaches for breaking HCP–MAb interactions will be discussed? We have observed that HCPs can interact with MAbs through several interactions (e.g., hydrophobic interaction, electrostatic interaction, and hydrogen bonds). For each type, a modifier can be designed to break that interaction. For example, sodium chloride can be used to break electrostatic interactions. In my presentation, I will provide additional examples and a list of different modifiers that were used to break different types of interactions.

How can a rational design help process development for HCP removal? By understanding the molecular properties of a MAb through identification of an HCP, we can predict a potential interaction with those HCPs. Then we can select more effective wash modifiers for a protein A chromatography column. Again, I will provide examples of three or four different MAbs and demonstrate the common HCPs that bound with them and what the specific HCPs are for each MAb. Then from there, based on some literation data and the molecular structure of the HCP and the MAb, we can predict the interaction mode and suggest a breaking strategy.

Other than mass spectrometry, are there other tools or software that help in this work? MS is really the main tool in this work. There is a huge amount of MS data that I will present. In addition, I will probably mention two other techniques that are also used in this work.

One is not really a technique, but a highly valuable database. The Chinese hamster ovary (CHO) protein sequence database was just completed and published at right timing for this work, and it effectively supports this work. Without that database, we can’t identify HCPs, especially for those relevant to industry applications. It is really highly valuable information on the use of this work.

In addition to regular MS, we also develop a two-dimensional high- performance liquid chromatography (HPLC) separation method. It significantly enhances the separation and eventually improves the accuracy of MS and database searches for the identification of HCPs.

Aside from speaking, why are you attending the BPI Conference? I have attended the BPI Conference several times and have really enjoyed the time there. I think it is a great place to see friends and previous coworkers and (more important) the people working on the same problems as myself in daily life. Also, this is a place to share information and bounce ideas, and it’s a great opportunity for social networking.

It’s a good conference with a lot of attendance from industry. People there are looking for more information, industrial trends, and new technologies.

>> Listen to the full interview

Matthew Traylor (Shire)

Matthew Traylor (analytical scientist at Shire) will be joining us for the Analytical, Formulation, and Quality track. The session “Linking Analytics with Critical Quality Attributes and Multiattribute Monitoring and Control” will take place on Tuesday morning, 27 October 2014. His presentation is titled “Implementing Multiattribute LC–MS Methods for More Informed Process Development.”

Abstract: Multiattribute LC–MS peptide mapping provides comprehensive characterization and quantitation of protein posttranslational modifications and impurities. Recent software advances have facilitated the routine application of this technology, enabling more informed decision making throughout process development. Case studies will demonstrate the implementation of multiattribute LC–MS during different stages of development.

In your abstract you share that recent software advances have enabled routine use of LC–MS peptide mapping. How was the technology used before and how is it applied now? Previously, MS software analyses had really focused on proteomic type workflows or MRM [multiple reaction monitoring] quantitative workflows. What I need to do is a bit different. I’m looking for a deep characterization of one specific protein out of a mixture. So, the proteomic-type software packages were not quite suitable for my needs. During the past several years, many packages have become available to address my needs.

Every MS vendor has its own package, including PepFinder (from Thermo Fisher), which is based on the mass analyzer software that was developed at Amgen, and the software packages based around Byonic (from Protein Metrics). These packages search MS data for heterogeneity in one specific protein. They are very good at finding all quality attributes of a specific protein.

The benefit of this type of software is that it helps automate the very tedious manual task of identifying different dimensions of heterogeneity in a protein sample. Also, it can quickly scan for unexpected modifications that you wouldn’t be able to find yourself, such as sequence variants.

How might this technology be used in laboratory-scale development as compared with pilot, plant, and production scales? Starting at the beginning of development when quality attributes are not yet assigned, LC–MS peptide mapping is very important and useful for discovering the types of posttranslation modifications (PTMs) and dimensions of heterogeneity that are present in a sample. This discovery- type workflow can be used with stressed, stability, forced degradation, and other types of structure and function studies to identify the dimensions of heterogeneity in your sample so you can understand how important those are.

In later stages of development, LC–MS peptide mapping can be useful in a testing group. Once these attributes have been discovered, then LC–MS peptide mapping with the various software packages that are now available can be used for routine quantitation. So now you’re in a testing group rather than running multiple methods for all those multiple attributes, and the intent is for the multiattribute LC–MS peptide mapping method to measure all of those and to more efficiently use your personnel resources in a testing group.

A long-term goal would be to implement this type of workflow in a quality environment. There would need to be a lot of upfront investment to properly validate the instrumentation, the software, and the methods before that can happen.

Is there anything else about LC–MS peptide mapping that you think the BPI audience would be interested in learning about from your talk? I think one important part of my talk will be going over some case studies. When you hear about peptide maps or peptide map analysis software from vendors, those vendors make the case that their software can do everything. I think it can be useful to hear case studies in which someone has actually applied different software packages to solve real-world problems. It gives someone who is interested in this kind of work a useful place to start and a useful direction to move in.

Aside from speaking, why are you attending the BPI Conference? The BPI Conference is especially interesting for the other presenters that will be there. These types of conferences are very useful to meet other people doing the type of work that I’m doing and to get broader feedback on the direction that we’re going at Shire.

>> Listen to the full interview

These interviews have been edited from transcripts for space and style.

Recovery and Purification Sessions

Tuesday, 27 October 2015 8:00–9:45 am Implementation of Continuous Processing 10:15–11:45 am Innovation at the Interfaces with R&D, the Harvest, and Formulations 1:25–3:00 pm Novel Approaches for Nonchromatographic Purification of Proteins 3:10–4:45 Keynote Presentations |

|---|

Wednesday, 28 October 2015 7:45–9:45 am Technology Workshop and Keynote Presentations 10:25 am–12:00 pm Improvements in Rapid, High-Throughput Process Development 1:40–3:15 pm Challenges and Impact of Emerging Modalities and Expression Systems on Downstream Processing 4:00–5:30 pm Advances in Host-Cell Protein Identification, Understanding, and Clearance |

Thursday, 29 October 2015 8:00–9:45 am Novel Chromatography Selectivities and Innovation in Materials Science for Next-Generation Purification 10:30 am–12:00 pm Improving Yield, Purity, Control, and Product Quality Attributes, in Downstream Processing 2:00–3:00 pm Innovation at the Interface with Formulations 3:30–5:00 pm Improving Process Performance in Clinical and Commercial Manufacturing |

Recovery and Purification Articles from the Archives Online at www.bioprocessintl.com

Han XJ, et al. Performance of a Salt- Tolerant Membrane Adsorber in Flow- Through Mode. February 2013.

Whitford W. Supporting Continuous Processing with Advanced Single-Use Technologies. April 2013.

Genest P, et al. Artifacts of Virus Filter Validation: Best Practices to Maintain the Scaled-Down Model. BioProcess Int. May 2013.

Müller-Späth T, et al. Purifying Common Light-Chain Bispecific Antibodies: A Twin- Column, Countercurrent Chromatography Platform Process. May 2013.

Champagne J, et al. A Salt-Tolerant Anion-Exchange Chromatography Sorbent for Flexible Process Development. June 2013

Gagnon P. Emerging Challenges to Protein A: Chromatin-Directed Clarification Enables New Purification Options. October 2013.

Langer ES. Industry Adoption of Membrane Adsorbers: Fastest-Growing Little Segment in Bioprocessing. October 2013.

Chollangi S, et al. Accelerating Purification Process Development of an Early Phase MAb with High-Throughput Automation: Part 1 of a Technical Report. March 2014.

Masser D. Enabling Greater Process Control and Higher Protein Titers: Advances in Downstream Single-Use Technologies. June 2014.

van der Meer T. Diatomaceous Earth Filtration Innovative Single-Use Concepts for Clarification of High-Density Mammalian Cell Cultures. September 2014.

Franzreb M, Müller E, Vajda J. Cost Estimation for Protein A Chromatography: An In Silico Approach to MAb Purification Strategy. October 2014.

Kling J. Upstream Efficients, Economic Forces, and Changing Technologies Complicate Separation and Purification. October 2014.

LeMerdy S. Evolving Clarification Strategies to Meet New Challenges. October 2014. Quinlan A. Advances in Chromatography Automation. January 2015.

Remington KM. Fundamental Strategies for Viral Clearance, Part 1: Exploring the Regulatory Implications. January 2015.

Holstein, M, Cotoni K, Bian N. Protein A Intermediate Wash Strategies. February 2015.

Metzger M, et al. Evaluating Adsorptive Filtration As a Unit Operation for Virus Removal. February 2015.

Ulmer N, et al. Affinity Capture of F(ab’)2 Fragments: Using Twin-Column Countercurrent Chromatography. February 2015.

Schreffler J, et al. Characterization of Postcapture Impurity Removal Across an Adsorptive Depth Filter. March 2015.

Chaudoreille S, et al. Optimization and Scale-Up of HCIC-Based MAb Purification Processes, Part 1. May 2015.

Chaudoreille S, et al. Optimization and Scale-Up of HCIC-Based MAb Purification Processes, Part 2. June 2015.

Remington KM. Fundamental Strategies for Viral Clearance, Part 2: Technical Approaches. May 2015.

Royce J. An Industrial Platform Solution for Antibody Fragment Purification. June 2015.

You May Also Like