EMD Millipore has developed a family of single-use bioprocess containers designed for mammalian cell growth and recombinant protein production. The Mobius® CellReady product offering includes bench-scale (3-L), small-scale (50-L) and pilot-scale (200-L) bioreactors spanning early process development through clinical batch production. To enable the successful scale-up of a biomanufacturing process, a number of factors critical to efficient cell growth, viability, and protein production were considered and used to develop an optimized design. These include mixing efficiency, gas transfer capability, and an operating range of power input that minimizes cell shear. In this study, several key design parameters such as oxygen mass transfer coefficient (kLa), power per unit volume, Reynolds number (Re), mixing time, and tip speed were characterized for the three different sized single-use bioreactor containers. Based on these data, CHO cells were cultured in each of these bioreactors by maintaining equivalent power per unit volume as the primary scaling parameter. The collective characterization and performance data provide evidence of cell culture scalability across the entire Mobius® CellReady bioreactor platform.

Volumetric Mass Transfer

One of the most critical parameters for scaling between bioreactors is their ability to deliver oxygen to the growing cells. The volumetric mass transfer coefficient for oxygen (kLa) was determined for various microsparger gas flow rates and impeller agitation rates using the static gassing out method with nitrogen and air. Results indicate that similar kLa values can be achieved in all three Mobius® CellReady bioreactors at the same power/volume by adjusting the gas flow rates, thereby demonstrating the scalability of the family of Mobius® bioreactors.

Mixing and Power Input

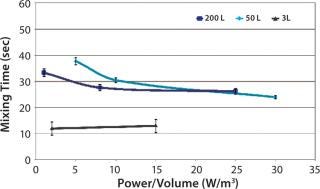

Mixing is a critical bioreactor performance characteristic because it is responsible for evenly distributing contents and maintaining control within the cell culture environment. Although no single scaling parameter can guarantee comparable process performance between stirred-tank bioreactor systems, choosing an agitation rate that matches energy dissipation or power/volume (W/m3) is a common first approach. As seen in Figure 1, mixing is rapid and efficient in all three Mobius® CellReady bioreactors.

Figure 1: ()

Cell Culture Performance

To demonstrate cell culture scalability, a batch CHO cell culture process was performed in 3-L, 50-L and 200-L bioreactors using power/volume as the primary scaling parameter. As Table 1 shows, cell culture scale-up was achieved by matching critical process parameters such as impeller speed (power/volume) and gas flow rates (kLa values).

Table 1: Impact of column diameter on column weight, bed volume, and slurry tank size

Table 1: Impact of column diameter on column weight, bed volume, and slurry tank size ()

About the Author

Author Details

A.K. Wood, K.T. Thiel, J.L. Simler, M.K. Thaker, and P.J. Rapiejko, EMD Millipore, 80 Ashby Road, Bedford, MA 01730; 1-800-MILLIPORE (1-645-5476), fax 1-781-533-3110. For complete details of this study, please visit www.millipore.com/mobius, reference DOC # PS3318EN00.