Content Spotlight

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

March 4, 2019

Adaptimmune says the only way an autologous T-Cell firm can control the evolution of production technologies is to have the process under its own roof.

Adaptimmune Therapeutics began working with contract development and manufacturing organization (CDMO) PCT – now known as Hitachi Chemical Advanced Therapeutics Solutions (HCATS) – in 2013 and entered into a five-year strategic partnership in 2016 for the manufacture of its autologous SPEAR (Specific Peptide Enhanced Affinity Receptor) T-cell cancer immunotherapies.

But the firm has also been building up its own inhouse capabilities, and in January 2018 opened a facility at the Navy Yard in Philadelphia, Pennsylvania. A year on, the firm says the facility is able to manufacture cells for up to 10 patients per month, similar to the capacity at HCATS, and adds it is scalable to 100 patients per month without significant capital expenditure.

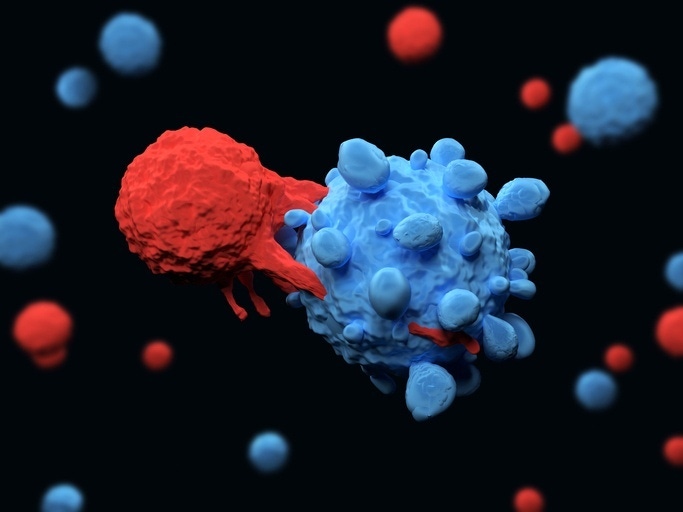

Image: iStock/Meletios-Verras

The firm’s CEO James Noble said the dual inhouse and outsourcing supply strategy – which Adaptimmune is replicating with its viral vector production – will both ensure control of the process and greater efficiency going forward.

“It is very difficult to end up at an advanced cost effective process if you are entirely reliant on a third party for that supply,” he told stakeholders during a 2018 Q4 financial call.

Furthermore, “I would go so far as to say that not having your own manufacturing is more catastrophic for an autologous T-cell company right now because the technology is still evolving and the only way you can control that evolution is to have the process under your own hands, under you own roof.”

Adaptimmune’s approach for its SPEAR products is based on making the harvested cells better at attaching to tumors through the modification of the genes that encode the cell surface proteins (T-cell receptors), which recognize and bind cancerous cells.

As these are autologous products, keeping the T-cell therapy as close to the starting material as possible avoids variations in cell count and according to Noble having your own manufacturing facility represents “an incredible advantage.”

You May Also Like