Content Spotlight

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

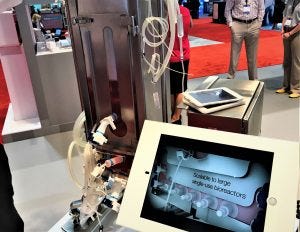

There is increasing demand for large-scale single-use bioreactors says Thermo Fisher as it prepares to launch disposable systems up to 5,000 L in volume.

Thermo Fisher Scientific showcased its latest bioprocess offerings at Biotech Week Boston earlier this month. This included an update to its HyPerforma DynaDrive single-use bioreactor (SUB) range, which will see the firm offer biomanufacturers disposable bioreactors with volumes more than doubling its current volume limit.

Single-use technologies have been fully adopted by the industry, but most manufacturers rely on systems with an upper limit of 2,000 L due to pressure challenges from the increased weight of liquid, infrastructure issues and costs. For large commercial production volumes, therefore, manufacturers opting to use single-use instead of stainless-steel can overcome the scale limitations by using a perfusion process or by running several bioreactors in unison.

Thermo Fisher going beyond 2,000 L SUB at Biotech Week Boston

But according to Kevin Mullen, senior product manager at Thermo Fisher Scientific, customers are now wanting larger sized single-use bioreactors, especially for cell cultures that do not work well in perfusion.

Therefore, the bioprocess vendor is launching a 3,000 L bioreactor in the first quarter 2020, Mullen told Bioprocess Insider. The bioreactor, made from Thermo Scientific Aegis 5-14 film, has been designed to fit in facilities made to house 2,000 L systems allowing biomanufacturers to install them without having to redesign their plants.

And in 2021, Thermo Fisher aims to go even bigger, launching a 5,000 L single-use bioreactor system.

Only one other bioprocessing vendor has a range of single-use systems above 2,000 L. ABEC launched a 4,300 L bioreactor (with 3,500 L of working volume) in 2015 and a 4,900 L system with a 4,000 L working volume in 2017.

And also at Biotech Week Boston, ABEC went even higher, announcing a single-use bioreactor system with a working volume of 6,000 L telling this publication it was a response from customers wanting greater economies of scale for cell culture production using disposable equipment.

Whether other vendors will follow suit and move into the super-sized single-use system space remains to be seen, but according to Mullen Thermo Fisher can be competitive with its full scale-up offering.

The firm has SUB systems within the DynaDrive portfolio at the 50 L and 500 L scale, and systems within its single-use HyPerforma ranging from benchtop to 2,000 L, meaning customers can use Thermo Fisher systems as they scale-up their products through the clinic all the way to commercial.

UPDATE 10/24: The article has been changed to reflect that Mullen’s comments stating that Thermo Fisher’s full-scale offering gives it a competitive advantage was in relation to the industry as a whole, and not in relation to ABEC. And, ABEC US headquarters are located in Bethlehem, PA.

ABEC has told us that they offer scalable single use bioreactors with available working volumes less than 50 L up to 6000 L, with the advantage that customers can choose any volume in that range (rather than just discreet 50 L, 500 L, 2000 L volumes), in order to accommodate their specific production needs and cost of goods targets. ABEC has also demonstrated the industry’s best bioreactor mixing and mass transfer performance, while other suppliers’ planned performance improvements won’t be available for many months.

You May Also Like