September 2018 Featured Report

Cell line development engineers in the biopharmaceutical industry juggle several, sometimes contradictory priorities. They must present their bioprocessing colleagues with a master cell line that can express a reproducibly high-quality protein product at titers and growth concentrations that will be high enough for manufacturing efficiency — and without those parameters degrading over time. Performing the first step in every bioprocess, these scientists must consider their own budgetary concerns and efficiencies while facing regulatory scrutiny under the 21st-century risk-management paradigm. In turn, they make demands on technology suppliers, asking, “Can we engineer our cell lines to obtain good productivity and genetic stability without screening so many clones? How do we best manage those screenings? What properties can we screen for? And how important is clonality, anyway?” The answers must come from biology enabled by improved instrumentation.

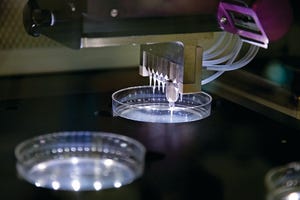

This laboratory at cell-therapy company Cellectis is one...

HTTPS://STOCK.ADOBE.COM

Health authorities are requesting substantial details from sponsors regarding practices used to generate production cell lines for recombinant DNA–(rDNA) derived biopharmaceuticals. Authorities also are asking for information about the clonality of master cell banks (MCBs) and control strategies to minimize genetic heterogeneity. Such requests are prompted by recent reports indicating “nonclonality” for certain production cell lines. To address these and related issues, the CASSS CMC Strategy Forum on “Production Cell Line Development and Control of Product Consistency During Cell Cultivation: Myths, Risks and Best Practices,” was held 23 January 2017 in Washington, DC. The overarching objective of this forum was to define myths about and risks to cell line development and product quality associated with cell cultivation. Forum participants identified current best practices to ensure that sponsors meet regulatory expectations when assessing and assuring the appropriateness of cell ...

Figure 1: A disposable sorting cartridge (LEFT) for the Cyto-Mine cell sorter and droplet dispenser; zoomed-in image of a cartridge in use (RIGHT); the red arrow denotes a single picodroplet.

Sales of monoclonal antibodies (MAbs) are predicted to be over US$125 billion by 2020 (

1

). Such revenue potential puts significant pressure on the biopharmaceutical industry to reduce timelines, especially to first-in-human trials. Cell-line development represents a large and critical portion of the early development timeline.

Whether a developer is using random or targeted integration for introducing genes into a host-cell genome, the regulatory requirement for addressing monoclonality introduces a time and resource-intensive step in this process. Many different techniques are used routinely in biopharmaceutical discovery and development workflows: single-cell analysis, sorting, imaging, and dispensing into individual wells of microplates (

2

). In addition, a productivity screening method such as minipool titerin...