As the biopharmaceutical industry continues to mature and grow, so too does the need to educate a broader audience of biopharmaceutical professionals interested in hearing, understanding, and applying the latest science and technology trends that support and in many cases are transforming today’s bioprocesses. To reach this extended and engaged audience,

BioProcess International

created the BPI Theater Series: a live, interactive program that provides bioprocessing content to traditional, noncore biopharmaceutical conference programs. It provides attendees with the opportunity to interact with leading biopharmaceutical industry experts as they present, discuss, and debate the impact of the latest scientific and technology trends related to the three pillars of biopharmaceutical development: upstream processing, downstream processing, and manufacturing.

BioProcess International

originally partnered with BIO to launch the BPI Theater series in 2007. Attendance has grown every year, and today it has becom...

https://bioprocessintl.com/wp-content/uploads/2014/06/062014_MichaelDavis.mp3

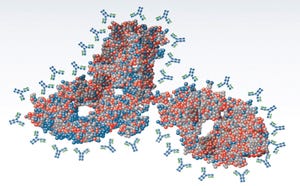

Great successes for monoclonal antibody (MAb)–based biologics over the past decade have provided many valuable options for patients combating some of the most serious diseases in the world, including cancer and autoimmune diseases. MAbs and antibody–drug conjugates (ADCs) are among the fastest growing biologic segments in development, with hundreds of candidates currently under clinical study.

Meanwhile, society is facing the challenge of increasingly higher costs in healthcare including the cost of pharmaceuticals. With an aging population in many parts of the world, striking a balance between providing an incentive for breakthrough medicine from innovator companies and controlling the high cost of medicines by means of national policy has motivated many governments to develop policies for approval of generic biologics. In 2012, the US Food and Drug Administration (FDA) released guidelines for development of biosimilars, paving...

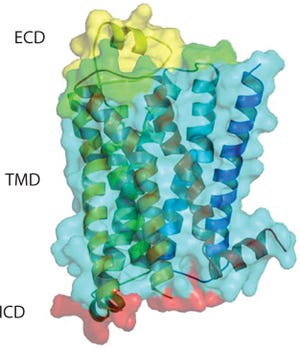

G -protein coupled receptors (GPCRs) represent a target superfamily linked to many disorders across all therapeutic areas. Although this target class has been historically treated by small molecules and peptides, antibodies can offer a number of advantages over such molecules by virtue of their specificity, dosing frequency, and restricted penetration. They also can provide other functional effects specifically mediated by the Fc region (ADCC and CDC) as well as different modalities such as those offered by bispecific and antibody drug conjugates.

&bgr;

1

AR Crystal structure depicting ECL2 in yellow

Similarly, a longer half-life in some instances (such as by FcRn-mediated recycling) can provide a therapeutic index that is more desirable than that of small molecules and peptides. In addition, antibodies can offer more diversity in pharmacological effects than provided by small molecules and peptides. This is because of the different nature of their extracellular interaction with a receptor compared with ...

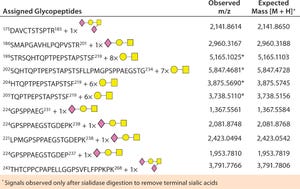

A large proportion of biotherapeutic products are glycoproteins. These include erythropoietin and other cytokines, antibodies, glycosyltransferases, and glycosidases, which together generate billions of dollars in sales worldwide. Such drugs are inherently complex. As new treatments emerge and biosimilars are evaluated, the need to better understand their molecular structures is more acute than ever.

Therapeutic glycoproteins are typically produced as recombinant products in cell culture systems. Glycosylation is of major importance during development of these drugs because their glycan chains markedly affect product stability, activity, antigenicity, and pharmacodynamics. A detailed description of the structural features for such carbohydrate-containing molecules is increasingly expected as part of their new drug applications (NDAs) or comparability protocols.

Product Focus:

Glycoproteins

Process Focus:

Manufacturing

Who Should Read:

QA/QC, product development, and analytical

Keywords:

Mass spectrome...

Qualification of Scale-Down Bioreactors: Validation of Process Changes in Commercial Production of Animal-Cell-Derived Products, Part 2 -- ApplicationQualification of Scale-Down Bioreactors: Validation of Process Changes in Commercial Production of Animal-Cell-Derived Products, Part 2 -- Application

https://bioprocessintl.com/wp-content/uploads/2014/06/Shimoni_Qualification-of-S-D_Bioreactors_May_2014.m4a

Here we apply our approach to validation of animal cell culture process changes using qualified, scale-down bioreactors. As described in

Part 1

(including Table 1, Figures 1 and 2, and References 1–23), the goal is to facilitate implementation for the benefit of both the patients and industry.

“Qualification of Scale-Down Bioreactors: Validation of Process Changes in Commercial Production of Animal-Cell–Derived Products, Part 1 — Concept”

appears on pages 38–45 of

BioProcess International’s

May 2014 issue.

Process changes often entail validation, but a common problem facing the industry is justifying the validation approach. Traditionally, process-development groups have performed validation at scale, in production, for the duration of a campaign. However, that entails dedicating production units of operation to the validation exercise and segregating commercial and validation materials from e...

https://bioprocessintl.com/wp-content/uploads/2014/06/062014-Masser-abstract.mp3

Downstream protein purification (the stage in which a protein is isolated and purified) is one of the last steps in biotherapeutic manufacturing. Single-use technologies are an increasingly popular choice for both upstream and downstream bioprocessing because they offer significant benefits over traditional multiuse manufacturing systems. Single-use technologies also provide an array of logistical benefits, including reduced costs, minimized risk of cross-contamination, and improved operational efficiency (

1

).

Challenges remain, however, in designing a complete, streamlined, single-use process for downstream protein purification. In-process sensor technologies, chromatography, and temperature control are all areas that have been traditionally underserved by single-use technologies and represent “weak points” in the downstream process flow. Exacerbating the problem, most proteins are heat labile and sensitive to a large numb...

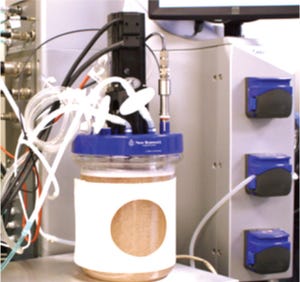

For BPI’s inaugural “Ask the Expert” webcast, Ma Sha (Eppendorf’s director of technical applications) fielded questions related to his upcoming poster presentation at IBC’s Single-Use Applications for Biopharmaceutical Manufacturing in Boston this month: “One Billion Mesenchymal Stem Cells in Eppendorf BioBLU 5c Single-Use Bioreactor 3.75-L Scale”. Eppendorf R&D Labs is formerly New Brunswick Scientific, which was acquired by Eppendorf in 2007.

Our focus recently had been large-scale stem-cell applications in bioreactors. We chose to work on mesenchymal stem cells because many are in clinical trials. At clinical scale, about a billion stem cells are needed per dose. Most current work is at a fairly smaller scale often using spinner flasks. So we developed a method to use microcarriers in shake flasks (instead of spinners). The Eppendorf S41i incubator shaker has a completely sealed chamber (like our CO

2

incubator).

We used fairly low-speed shaking (50–70 rpm) that doesn’t require clamps, so you can put ...

A newly launched independent, nonprofit organization — the National Biomarker Development Alliance (NBDA) — will broadly engage leaders in industry, academia, patient groups, and government from across the United States. It was announced on 13 January 2013 at the National Press Club by the Research Collaboratory (RCASU) at Arizona State University (ASU). The mission of the NBDA is to address the complex and urgent challenge of creating standards needed for end-to-end, systems-based biomarker research and development (R&D). The alliance is meant to advance molecularly based precision (personalized) medicines for the future.

The NBDA is the first independent, cross-sector organization that brings together all key stakeholders for the purpose of improving the currently dismal success rate of biomarker R&D. Creating the standards and systems for successful biomarker development is complex but achievable through networks of experts who can solve problems of this scale.

“We were pleased to enable development of...