August 2018 Featured Report

Yan Zhi

, program design technical lead, Fujifilm Diosynth Biotechnologies

Fujifilm Diosynth Biotechnologies (FDB) is a world-leading contract development and manufacturing organization (CDMO) with over 25 years of experience using biologicals and more than 310 projects including six licenses. Production sites are located in North Carolina and Texas. In Texas, the flexible biomanufacturing facility can handle production from preclinical to current good manufacturing practices (CGMP) commercial manufacturing. Facilities and capabilities include state-of-the-art process development; mobile cleanroom (MCR) technology with fully segregated and self-contained units that can be connected as needed for upstream, recovery, and downstream; nearly exclusive use of single-use technology; fully functional process and analytical development, including virology sections; an extensive quality system; and high-speed robotic viral product fill-in-place that will be up and running by late 2018. Texas FDB specializes in dev...

byYan Zhi

BioProcess Insider

brings the news as it breaks. At the BPI Theater @BIO, editor Dan Stanton conducted a series of interviews live on stage to report on the latest movements in the biomanufacturing industry to start each busy day of dealmaking in Boston. Below we summarize his

DAY ONE

conversations with a number of biopharmaceutical executives on Tuesday 5 June 2018. You can watch the full interviews online at www.bioprocessintl.com/BIO-Theater-2018.

Andy Topping, Chief Scientific Officer, Fujifilm Diosynth Biotechnologies

Gene therapies show great promise, and future demand is growing. Current manufacturing capabilities are not adequate to keep up with current demand. Contract manufacturing organizations (CMOs) such as FDB are running to keep up with new products. New companies are looking for early phase services. Early phase manufacturing isn’t really manufacturing per se; it entails laboratory processes performed in a different environment. The laboratory environment is challenging for making enoug...

Nina Bauer,

associate director of autologous cell therapy commercial development, Lonza Pharma and Biotech

Lonza Emerging Technologies is focusing on cell and gene therapies. Lonza now has expertise in different cell and vector types, constructs, process and assay development, and platform technologies for both clinical and commercial manufacturing. This includes taking a concept through commercial manufacturing.

Lonza just opened a site in Houston, TX, and another in the Netherlands, as well as partnering with Nikon in the Asian market. Cell and gene therapies have a market growth currently of 27% with more than 500 cell and gene therapy companies worldwide developing over 1,300 products. Although Lonza has been focused on large manufacturing of bulk drug substance, the company made a market assessment and came to realize that the market was moving toward patient-specific therapies, specifically with allogeneic and autologous therapies (48% of development pipeline), and has added those to its business.

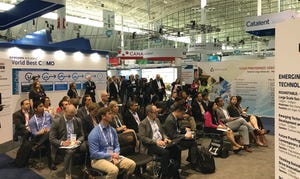

The 2018 BPI Theater at BIO

Richard Grant, chief product officer, FloDesign

FloDesign is experimenting with applications of acoustics to cell-therapy manufacturing. An electric transducer is attached to a closed-flow system and generates forward propagating waves that are reflected as backward propagating waves. This sets up three-dimensional standing waves within the cell (flow) chamber. When cells enter the flow channel, acoustic forces cause then to cluster within the nodes of those standing waves, ultimately settling out through enhanced gravitational means.

Acoustic cell processing is scalable and reduces cost of goods (CoGs), consolidates and simplifies manufacturing, and maintains the high quality of products.

FloDesign is developing equipment for automation within a closed system, which will use modular disposables and an acoustic “engine” with integrated, automated fluid handling. The first system that will be released is a concentration/wash. The system works with Infinity beads for cell selecti...

This roundtable took place on Tuesday, 5 June 2018, in the BioProcess Theater at the BIO International Convention in Boston, MA. (Left to Right)

Moderator:

Patricia Seymour, senior consultant at BioProcess Technology Consultants, Inc.

Panelists:

Jennifer Michaelson (vice president of preclinical research and early development at Cullinan Oncology), Weichang Zhou (senior vice president and chief technical officer at WuXi Biologics), Michael Kaufman, senior vice president, CMC, at Mersana Therapeutics), and John Lee (senior vice president of pharmaceutical development at Decibel Therapeutics)

Moderator Patricia Seymour, with John Lee, Michael Kaufman, Jennifer Michaelson, and Weichang Zhou

Following introductions of the panelists and their companies’ technologies, moderator Patricia Seymour began the discussion about challenges related to choosing different modalities and addressing related manufacturing concerns.

Targeting Modalities

Michaelson began by describing how Cullinan Oncology selects its targ...

This roundtable took place on Tuesday, 5 June 2018, in the BioProcess Theater at the BIO International Convention in Boston, MA. (Left to Right)

Moderator

: Dan Stanton, editor,

BioProcess Insider

.

Panelists

: Ohad Karniel (CEO and cofounder of Atvio Biotech, ISCT process and product development co-chair), Alan Moore (vice president and commercial chief for advanced therapies, WuXi AppTec); and Dr. David Brindley (University of Oxford and Harvard University)

Moderator Dan Stanton, with Ohad Karnieli, Alan Moore, and David Brindley

Moderator Dan Stanton introduced the second roundtable of Tuesday morning by commenting on the recent spate of approvals for CAR-T cell and gene therapies. With large biopharmaceutical and biotechnology companies devoting scientists and funds toward these next-generation therapies, contract manufacturing organizations (CMOs) also are investing in opportunities to expand capacity and expertise.

As the panelists introduced themselves, they raised two key points for discussion:

Michelle Zengh, chief operating officer, MabPlex International Company Ltd.

MabPlex presents a complete solution from gene cloning to antibody–drug conjugate (ADC) fill–finish with a timeline from gene cloning to an investigational new drug application (IND) in 22 months. The company has facilities in San Diego and in China. It can perform cloning and high-yield stable cell-line development, process development and scale-up, CGMP quality and kilogram-scale monoclonal antibody (MAb) and payload manufacturing, large-scale conjugation (150–500 L), large-scale purification, formulation, and fill–finish.

Based on the target disease and cell type, MabPlex and its clients can choose from a number of different linker–toxin combinations and use different conjugation technologies. This creates a substantial set of ADCs that clients can screen to determine the most effective ADC for their needs. The company has experience with traditional cysteine conjugations using maleimide, lysine conjugation, nonnatural amino ac...

BioProcess Insider

brings the news as it breaks. At the BPI Theater @ BIO, editor Dan Stanton conducted a series of interviews live on stage to report on the latest movements in the biomanufacturing industry to start each busy day of dealmaking in Boston. Below we summarize and share the videos from his

DAY TWO

conversations with a number of biopharmaceutical executives on Wednesday 6 June 2018.

Jacobs offers a range of services — including advanced planning and programming, design, construction, commissioning, qualification, and validation — and has been involved in a number of large biomanufacturing facility projects. “We’re seeing now a tale of two facilities in some ways,” Sommer began, “the need for capacity in traditional stainless steel manufacturing facilities to pump out as much product as possible and the need for disposable facilities with quick product turnover and high flexibility.”

Having begun in the early 1990s, Jacobs benefits from a business model that expands capabilities through acq...

Scott Battist and Willfredo Mateo

Scott Battist

, vice president, general manager, and site head for the drug substance plant, Emergent Bio

BJ Hull

, vice president, general manager, and site head for the drug product plant, Emergent Bio

Willfredo Mateo

, director of MS&T for the Camden fill–finish plant, Emergent Bio

Emergent Bio started by producing treatments for an anthrax emergency. Traditionally, this has been a biodefense company with contracts from the US government. The company is focused on providing specialty products for civilians and military members that address accidental, intentional, and naturally emerging public health threats. It also works as a contract manufacturing organization (CMO) with sites in 10 global locations, has six manufacturing locations including in Canada, and employs more than 1,100 people. Emergent Bio has manufactured vaccines against anthrax and smallpox, and botulism antitoxin as well as treatments for exposure to nerve and chemical agents. Currently, it is partner...

The 2018 BPI Theater at BIO

Igor Fisch

, chief executive officer, Selexis, SA

Fisch first posed this question: “How can we accelerate the number of drugs going into the clinics?” Speed matters because the faster a drug can get into clinical testing, the faster it can make it to market. He discussed both Selexis and KBI Biopharma and their collaboration, which started in 2012 when KBI developed a heterodimer purification process. JSR acquired both companies with an interest in entering the life sciences business.

Selexis has best-in-class cell-line development and manufacturing. It has been a part of more than 100 clinical programs, three commercial products, 154 patents, and nine key technology launches. KBI has 101 product development programs, 101 manufacturing batches, over 12 investigational new drugs (INDs) per year, and more than 240 analytical services projects. It has collaborated on 10 Selexis cell lines.

Using the SURE

technology

platform, the companies work together for speed and high-performa...

Cristy Botens

, product manager in bioprocessing, Distek

Innovation is important, Botens began, and the focus should be on patients. Every innovation means that medicine gets to patients faster or has fewer side-effects. Recent pharmaceutical innovations include the first new Lupus treatment approved in 50 years, a gene therapy cure for inherited blindness, gene therapies for rare diseases, new chimeric antigen receptors on T cells (CAR-T) clinical trials (over 180 trials now), personalized cell therapy, and a vaccine that prevents cervical cancer.

The book,

The Other Side of Innovation

, by Vijay Govindarajan and Chris Trimble (

1

), lists three traps that can prevent innovation from happening: physical, when companies have invested in certain technologies or equipment and cannot afford fresh technology; psychological (“we can’t fail”), when they choose to stay with what originally made them successful and fail to notice or consider new ideas; and strategic, when they fail to anticipate the future.

What...

The 2018 BPI Theater at BIO

David J. Kenyon

, senior director of global scientific and technical affairs, Patheon (Thermo Fisher Scientific)

Kenyon has over 25 years of experience in the pharmaceutical/biotechnology and vaccine industries. He began his career with Johnson and Johnson, where he managed the production of the first monoclonal antibody (MAb) approved for human therapy. He joined Patheon in 2014. Kenyon received his PhD from the Rutgers School of Medicine and Dentistry of New Jersey.

Patheon is now part of Thermo Fisher Scientific. Thermo Fisher provides 400,000 customers worldwide with life sciences solutions, laboratory products, analytical instruments, and specialty diagnostics. Patheon is part of its pharma services group. The company provides process development services, clinical trial manufacturing, support, and logistics; and commercial manufacturing.

Data from the US Food and Drug Administration (FDA) show that the volume and approval pace of biologic therapies is accelerating. For in...

This roundtable took place on Wednesday, 6 June 2018, in the BioProcess Theater at the BIO International Convention in Boston, MA. (Left to Right)

Moderator:

Tom Ransohoff, vice president and principal consultant, BioProcess Technology Consultants, Inc.

Panelists:

Chris Love (a professor at MIT), Jorg Thommes (head of CMC at the Bill and Melinda Gates Medical Research Institute), Geoffrey Hodge (chief technical officer at UNUM Therapeutics), and Rajesh Beri (technical director for biomanufacturing, research and technology, at Lonza Pharma and Biotech)

Moderator Tom Ransohoff, with Jorg Thommes, Chris Love, Rajesh Beri, and Geoffrey Hodge

For biopharmaceuticals to mature as a process industry, companies need to embrace the ability to adopt new technologies and bring new operational approaches to their biomanufacturing facilities. In this roundtable about adopting and implementing new technologies in the biologics industry, moderator Tom Ransohoff stressed the importance of understanding drivers for ado...

This roundtable took place on Wednesday, 6 June 2018, in the BioProcess Theater at the BIO International Convention in Boston, MA. (Left to Right)

Moderator:

Dan Stanton, editor,

BioProcess Insider

.

Panelists:

Roger Lias (president and CEO, Avid Bioservices), Weichang Zhou (chief technology officer at WuXi Biologics), Jenifer Wheat (head of commercial development for mammalian manufacturing at Lonza Pharma and Biotech), and Jim Vogel (founder and director of The BioProcess Institute)

Moderator Dan Stanton, with Weichang Zhou, Jenifer Wheat, Roger Lias, and Jim Vogel

Single-use technologies (SUTs) are now prevalent within bioprocessing, but does this spell the end of industry’s historic reliance on stainless steel and fixed facilities? This roundtable was formed to discuss the wealth of investment in single-use (SU) equipment and flexible manufacturing solutions by contract development and manufacturing organizations (CDMOs) over the past few years, pitting that against what looks like a resurgence i...

Gustavo Mahler

, president and chief executive officer, AGC Biologics

AGC Biologics is one of the largest global biologics contract development and manufacturing organizations (CDMO) specializing in clinical and commercial development of therapeutic proteins. It has developed more than 200 products, both mammalian and microbial, from preclinical to commercial on all scales. The company’s CGMP facilities are located in the United States, Europe, and Japan.

AGC Biologics’s technologies and strategies to accelerate time to market include standardized cell-line and cell-bank creation and use of high-throughput technology for process and analytical development needed to apply for an investigational new drug (IND). By using a standardized quality by design (QbD) approach to process validation and high-throughput technology for process characterization, the company can accelerate process characterization. It also will assist clients in creating a long-term production strategy.

When developing your cell line, do ...

Greg Adams

, senior director of global analytical strategy and development, Fujifilm Diosynth Biotechnologies (FDB)

“Proteins have personalities.” Adams began. Their three-dimensional structures and folding patterns influence how each protein will behave. Analytical methods that evaluate a protein’s quality attributes need to be reproducible and robust. Proteins are evaluated through elucidating their amino acid sequences, using molecular informatics and modeling, characterizing three-dimensional structures, and understanding the degree of posttranslational modifications. The resulting knowledge will help you ensure consistency and safeguard methods.

Adams discussed identifying the critical quality attributes of proteins and offered as examples proteins expressed by

Escherichia coli

and mammalian cells as well as a monoclonal antibody (MAb). The examples highlighted problems that can occur with each type of protein. Those unique problems need to be considered during development. When approaching the cli...

Andrew Sandford

, vice president of business development, Catalent Biologics

Catalent feels strongly about “Patients First.” The core of the company’s mission is to “enhance and improve the lives of your patients.”

Bringing a new drug to market is expensive, costing about US$2.6 billion per drug. It takes an average of 12 years from drug discovery to final approval, with only 1 in 5,000 products ultimately approved by the Food and Drug Administration. The expense, risk, and long timelines of drug development are driving the search for efficiencies.

If you are working with multiple service providers that all offer different expertise, time and complexity will be added to your development. It is much more efficient to use one provider that can go from preclinical work to fill–finish and labeling and ultimately manufacturing a commercial product. Catalent is strictly a service provider with significant investment in people and capital. The company can start with a gene sequence, move to developing a cell lin...

Eunyoung Yang

, team leader and chief development officer of the business development team, Samsung BioLogics

Samsung is maximizing customer satisfaction by providing customized, cost-effective, and comprehensive development and manufacturing services. It is the number-four company in the world worth, US$92.3 billion, with 672 offices in 91 countries and employing 512,000 people. Samsung provides electronics (its most well-known business), engineering and construction for heavy industries, financial services, and healthcare support including biologics manufacturing, a medical center, and electronic medical devices.

Samsung BioLogics was founded in April 2011 as a one-stop provider of services from cell-line development to clinical manufacturing to commercial manufacturing and production of drug products. It is a fully integrated contract development and manufacturing organization (CDMO) with the largest capacity in the world. Samsung can help with any stage or all stages for any-sized client. It signed a ...

Sun Ra Bullins

, director of manufacturing, Avid Bioservices

Avid Bioservices is a dedicated commercial contract development and manufacturing organization (CDMO) with over 13 years of commercial manufacturing experience. It received six CMO leadership awards in 2018. Avid has a new state-of-the-art facility (2016) in Myford, CA, which has been designed for fully disposable manufacturing with up to 2,000-L capacity; and a legacy commercial facility with stainless steel bioreactors up to 1,000 L in Franklin, CA.

In designing the Myford facility, Avid specified that it meet strict commercial compliance standards, use technologies that meet the needs of a variable client base, and be a flexible facility that could make changes based on different process and product needs. The design focused on personnel and process flows, with the plant up and running in 13 months.

The perks of implementing single-use technologies (SUT) include their inherent flexibility and an ability to work on varied processes and product...

Molly McGlaughlin and Jim Stout

Molly McGlaughlin

, director of strategy and business development, BioVectra

Jim Stout

, director of process science, BioVectra

McGlaughlin introduced BioVectra. The company has been in business for 45 years and is based in Canada. Its a well-established contract development and manufacturing organization (CDMO) and fine-chemical manufacturer, and is a subsidiary of Mallinckrodt Pharmaceuticals. BioVectra started out as diagnostic reagent company and now has a complementary set of niche capabilities. From 10 years of fermentation experience, it was a logical progression to the fermentation of biologics.

In Windsor, Nova Scotia, BioVectra is building a modern microbial biologics facility that can develop biopharmaceuticals from cell lines to filing of biologics license applications (BLA). It will be equipped to work with a range of biosafety level-one expression systems and manufacture proteins, enzymes, antibody fragments, peptides, and attenuated virus vaccines. In resp...

At the BPI Theater @ BIO, editor Dan Stanton conducted a series of interviews live on stage to report on the latest movements in the biomanufacturing industry to start each busy day of dealmaking in Boston. Below are the videos from conversations with David Lucchino, chairman, Mass Bio; and Mark Day, president and chief executive officer, Bioasis.

Massachusetts: Secrets to Success

Lucchino explains that when you have a set of companies in an area, it lays the groundwork for growth of similar companies to locate there. Massachusetts has this in core biopharmaceutical areas, and looks to grow in cell and gene therapies. Massachusetts has a strong level of research and development at the academic institutions, and the state has set up a regulatory environment for easy expansion into commercial manufacturing. The trained workforce from Northeastern and MIT feeds the companies as they grow.

The plan of Mass Bio is to continue to develop the biotech industry in the area. One area of focus currently is in IT, a...