Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

June 10, 2020

Sponsored by Astrea Bioseparations

Astrea Bioseparations is the only adsorbent supplier that can discover new affinity ligands designed to bind selectively to a molecule of interest or specific impurity, develop efficient purification adsorbents and downstream methods, and deliver industrial-scale adsorbents (up to 1,000-L batch sizes) as loose slurry or in good manufacturing practice (GMP)-ready columns. With over 30 years of experience in development of affinity products and design and manufacture of new custom adsorbents, Astrea Bioseparations is a world leader in its field. The company offers an extensive range of off-the-shelf bioseparation products for recovery and purification of biologicals and removal of specific impurities — as well as extensive purification services, including state-of-the-art ligand screening technologies, custom-designed chromatography adsorbents, process development, and large-scale adsorbent manufacturing using the proprietary PuraBead agarose base matrix.

Astrea Bioseparations is the only adsorbent supplier that can discover new affinity ligands designed to bind selectively to a molecule of interest or specific impurity, develop efficient purification adsorbents and downstream methods, and deliver industrial-scale adsorbents (up to 1,000-L batch sizes) as loose slurry or in good manufacturing practice (GMP)-ready columns. With over 30 years of experience in development of affinity products and design and manufacture of new custom adsorbents, Astrea Bioseparations is a world leader in its field. The company offers an extensive range of off-the-shelf bioseparation products for recovery and purification of biologicals and removal of specific impurities — as well as extensive purification services, including state-of-the-art ligand screening technologies, custom-designed chromatography adsorbents, process development, and large-scale adsorbent manufacturing using the proprietary PuraBead agarose base matrix.

Early stage application of affinity chromatography in downstream processing is advantageous to increasing yields and reducing overall cost of goods (CoG). But as protein engineering technologies produce increasingly diverse therapeutic proteins — whole molecules, fragments, and fusion proteins — few if any standard affinity adsorbents are available for the newest modalities. In the absence of suitable existing ligands, development of completely new ligands is analogous with that of novel drug compounds and uses the same computational techniques. Astrea has adapted and used those technologies to support several stages in the affinity-ligand design process and to gain an understanding of target proteins and their interactions with adsorbents.

With extensive knowledge of in silico modeling techniques, we successfully apply a bioinformatics suite to identify lead candidate adsorbents in a range of projects. We also use a number of techniques in a custom ligand-discovery program:

Diverse or focused ligand selection from a virtual chemical space and a physical triazine-based library of about 1,000,000 compounds

Rapid screening of extensive peptide libraries, extending our ligand library to >34 million ligands

Evaluation of potential binding sites using structural/functional importance and blind-docking “roaming” of ligands to target proteins (using crystallographic information)

Screening of designed combinatorial libraries to explore the surrounding chemical space of lead screening hits

Investigation of spacer arm composition and length.

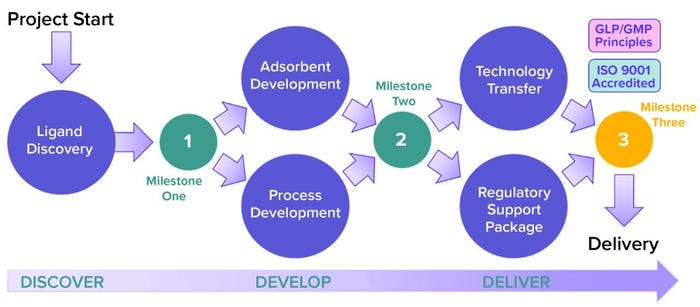

Figure 1: Astrea Bioseparations ligand discovery, adsorbent development, and manufacturing delivery process

Multimodal Ligands

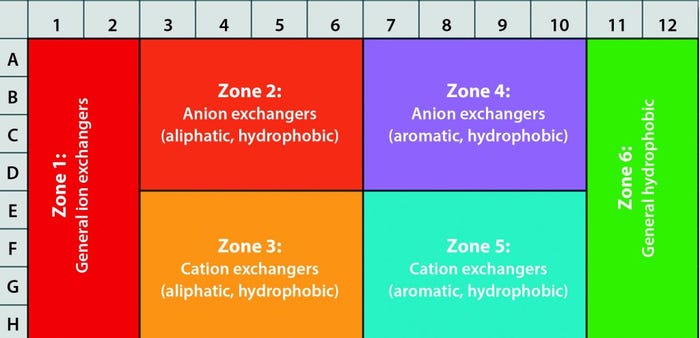

Before initiating a full development program, some clients choose to perform initial screening work themselves. To support that, we have developed a screening tool: the Multi-Mode Mimetic Ligand library (MMM library). It provides a diverse library of 96 ligands that can be used for in-house initial-phase screening to speed up ligand selection and eliminate the need for protracted contractual discussions. An easy-to-use, rapid screening toolbox, it can help identify chromatography adsorbents for a wide range of applications, including both product capture and polishing. No sample conditioning is required.

Users select the ligand that binds best under sample conditions, thereby eliminating the need to adjust samples and risk product loss. Based on 96 different ligands designed for structural diversity, with a cross-linked agarose matrix, this proven technology provides a toolbox for rapid screening without sample adjustment. It is cost effective and easy to use, with robust and stable adsorbents and scalable technology in a universal platform.

Isle of Man production suite

Once a suitable ligand has been identified, we can move on to adsorbent development. During this phase, we aim to optimize capacities, purities, elution, clean-in-place (CIP) conditions — as well as the synthesis process itself to facilitate technology transfer and production. Our development process incorporates the concepts of quality by design (QbD) with high scientific rigor. Technology transfer then takes adsorbent manufacturing to our established production facility on the UK Isle of Man. It can supply bulk adsorbent gel slurry for both developmental and regulated current good manufacturing practice (CGMP) applications in volumes sufficient to meet the requirements of even the largest biomanufacturing processes. All Astrea Bioseparations products are supported by comprehensive regulatory-support files and produced in that controlled-environment manufacturing facility under an ISO 9001 quality management system.

Figure 2: Multi-Mode Mimetic Ligand library layout

Chromatographic Profiling

MMM libraries are useful tools for process engineers who need to identify rapidly those ligands that will capture target proteins and/or remove specific protein impurities. Agarose-immobilized ligands can be applied successfully to both bind–elute product capture and flow-through polishing applications. Both goals can be achieved without pH or salt adjustments to the starting feedstock.

Astrea’s diverse libraries contain combinations of ionic and hydrophobic groups to enable rapid identification of effective ligands for polishing steps. Such diversity also enables customers to investigate the propensity of their proteins to interact with different types of ligands under defined conditions. Once candidate ligands have been identified, Astrea can readily provide larger quantities of each adsorbent for further development and scale-up studies. The company has infrastructure in place for producing large volumes of adsorbents/ligands — to GMP standards (if required).

This represents a change of paradigm for multimodal ligands: selection of ligand to suit the capture of impurities from an existing protein solution rather than adjustment of that solution to suit a given ligand. That enables rapid development of purification steps for high product purity and yield with retention of biological activity. Combined with the introduction of new prepacked disposable column formats, Astrea Bioseparations offers unique solutions to support continuous chromatography and flow-through polishing applications.

Further Reading

Beacom B, et al. Multi-Mode Mimetic Ligand™ Library: A Rapid Screening Toolbox for Target Protein Purification. BioProcess Int. poster 20 December 2016; https://bioprocessintl.com/poster-hall/multi-mode-mimetic-ligand-library-rapid-screening-toolbox-target-protein-purification.

Burton S. The Multi-Mode Mimetic Ligand™ Library: A New Tool for Rapid Development of Downstream Processes. BioProcess Int. sponsored report April 2018; https://bioprocessintl.com/sponsored-content/the-multi-mode-mimetic-ligand-library-a-new-tool-for-rapid-development-of-downstream-processes.

Andy Davies is sales and marketing director at Astrea Bioseparations Ltd., Horizon Park, Barton Road, Comberton, Cambridge CB23 7AJ, UK; 44-1223-433800; www.astreabioseparations.com. Multi-Mode Mimetic Ligand is a trademark of Astrea Bioseparations.

You May Also Like