- Sponsored Content

Combining Novel Jetting Manufacturing Technology with a New, Alkaline-Stable Protein A Resin

August 3, 2019

Sponsored by Purolite

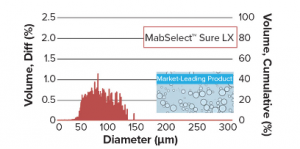

Praesto® Jetted A50 is the first protein A resin to meet the future demands in monoclonal antibody (MAb) processing today. It delivers enhanced performance characteristics through Purolite’s patented manufacturing technology: Jetting. This continuous manufacturing process — combined with a novel, alkaline-stable continuous manufacturing process with a novel, alkaline-stable protein A ligand called NGL Impact A™ (supplied by Repligen Corporation) — results in the only bioprocess-scale agarose available with a uniform particle-size distribution. Compared with other resins, Praesto®

Praesto® Jetted A50 is the first protein A resin to meet the future demands in monoclonal antibody (MAb) processing today. It delivers enhanced performance characteristics through Purolite’s patented manufacturing technology: Jetting. This continuous manufacturing process — combined with a novel, alkaline-stable continuous manufacturing process with a novel, alkaline-stable protein A ligand called NGL Impact A™ (supplied by Repligen Corporation) — results in the only bioprocess-scale agarose available with a uniform particle-size distribution. Compared with other resins, Praesto®

Jetted A50 resin delivers superior performance characteristics such as:

Ultrahigh dynamic binding capacity of ~80 g/L

Threefold increase in productivity

Exceptional alkaline stability for hundreds of cycles

Improved flow properties

No fines, decreased resin fouling, and improved lifetime

Up to 40% reduction in buffer volume

80% reduction in resin costs.

Fill out the form below to read the complete technology review now.

You May Also Like