Corning CellSTACK cell culture chambers can help deliver more yield with less labor, especially when configured as closed systems.

As viral vectors continue to push gene therapy innovations closer to market, many researchers are setting their sights on optimizing transfection, the process of delivering corrective genetic material into cells. It’s not just a question of how to transfect them, but also how to do so efficiently and at high volumes. Approaches that work for one cell line might not perform well for others, and transfection protocols can have different implications for scalability and cost during production for clinical trials.

For those and other reasons, experts usually reply, “It depends,” when asked about the best transfection strategies for gene therapy programs based on adenoassociated virus (AAV). As a senior bioprocess application scientist at Corning Life Sciences, Ann Rossi Bilodeau often receives questions from researchers about which approaches they should apply: Should they use suspension or adherent cell culture systems? Is one transfection reagent preferable to another? How long should a transfection process run? Bilodeau explains that which strategy to use “depends greatly on what you’re trying to achieve in the end, and there’s not just one right or wrong approach. From cell lines to platforms, facilities, and individual researchers, many factors can influence transfection — and a process should be optimized to account for all of them.” Best practices are worth exploring, however, as Bilodeau and experts from reagent supplier Polyplus-transfection demonstrate herein.

Transfection Methods for Viral Vectors

The primary question with transfection is how to do it. AAV-based gene therapy research generally relies on chemically mediated transfection. Compared with complex and expensive processes such as electroporation and microinjection, chemical transfection is easy to use and thus considered to be the gold standard in cost-efficient upscaling.

Cassie-Marie Peigné, a scientific support specialist at Polyplus-transfection, explains, “Most AAV therapies involve human embryonic kidney (HEK)293 cells, which are transfected easily using chemical reagents. When developed specifically for viral vector production, such reagents are as good as it gets in terms of reproducibility and robustness, negating the need for more expensive methods of physical transfection.”

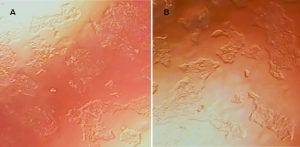

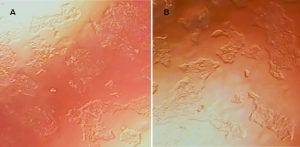

Figure 1: Confluence of human embryonic kidney (HEK)293T cells in the top (A) and bottom chambers (B) of a Corning CellSTACK 10-layer vessel on the day of transfection; images were acquired using a Bysameyee handheld USB microscope at 1000× magnification.

Considerations for Platform and Scale

Choice of platform can influence selection of transfection agents, but neither adherent- nor suspension-based culture systems offer clear advantages over the other in terms of effectiveness. Both platforms are compatible with transfection, and the choice of vessel has more to do with cell growth than with cell transfection.

“It takes time to optimize transfection for adherent cells and for cells grown in suspension,” says Alengo Nyamay’antu, a scientific communication specialist at Polyplus-transfection. “The important thing is that you optimize.”

If researchers are unsure about which platform to choose, Peigné suggests considering timelines and scales. “Adherent platforms are conventional methods to generate good titers quickly, and such processes are already well established in manufacturing facilities.” Adherent-culture vessels might be limited to scale-out rather than scale-up processes, which can present challenges for labor and manufacturing footprints. But options such as Corning CellSTACK, HYPERStack, and CellCube platforms can help increase yields and decrease labor requirements compared with single-layer vessels, especially when configured as closed systems. Whereas suspension tanks and transfection reagents can facilitate scale-up, such platforms require additional time to optimize for cell viability and quality, especially when working with suspension-adapted cells.

Keep in mind that scale goes both ways — and that scaling down might be just as important as scaling up. Bilodeau says, “Using scalable vessels and transfection reagents helps you move across scales with relative ease. If you need to go back and optimize, you can troubleshoot your process on a small scale before carrying it back through to manufacturing. Often, having a well-characterized process is more important than simply maximizing production.”

Meaningful Results

Transfection for viral vectors can be a daunting undertaking, but it doesn’t need to be. To arrive at a meaningful result efficiently, researchers need to know the hallmarks of successful and unsuccessful processes. Peigné points to a problematic “tendency to assume that transfection efficiency fully correlates with viral titer, which is not the case. If you’re performing optimization, then you always should consider the results in terms of viral titer at the end of your process.”

Researchers also should feel comfortable asking for support. Suppliers such as Polyplus-transfection and Corning Life Sciences can help scientists select the right products for their objectives. Peigné says, “If you’re starting a new process, it’s always helpful to contact suppliers to ensure that you’re beginning with an optimal combination of platform, media, reagents, and other factors.” Suppliers also can help determine “that you’re operating with the correct guidelines beforehand. Knowing where to look can save considerable time.”

Helpful Hints for Transfection

Manage Confluence: Transfection efficiency depends greatly on cell health. Maintain cultures below 80–90% confluence with regular subculture, and conduct transfections on healthy cells (e.g., early passage, mycoplasma negative). Do not allow cells to become overconfluent before subculture because contact inhibition will slow cell growth and thus diminish transfection efficiency.

Know Your Protocols: Follow a transfection protocol or guidelines for use. Sometimes seeding densities and times in culture before transfection must be adapted for different cell types and applications, provided that cells are dividing actively at the time of transfection.

Mitigate Detachment: If adherent cells detach from a vessel surface in response to protein or viral vector expression or because of toxicity, seeding cells on specific surfaces (e.g., Corning CellBIND surface) before transfection can enhance attachment.

Optimize Reagents and Raw Materials: Be sure to use only high-quality plasmid preparations that are free from proteins, RNA, and endotoxins.

Adjust the amount of plasmid DNA and the reagent-to-DNA ratio in your process to increase its transfection efficiency.

Cell toxicity sometimes occurs after transfection. If toxicity is observed, then decrease your reagent-to-DNA ratio or the amount of plasmid DNA used in your process. (Doing so is especially important if the protein that is expressed is toxic.) It might also be necessary to change culture medium four to six hours after transfection.

Use a regent (e.g., PEIpro linear polyethylenimine reagent) that is suitable for transfections in the presence of serum and antibiotics. When using a serum-free medium, be sure that it permits transfection.

Ann Rossi Bilodeau is senior bioprocess applications scientist at Corning Life Sciences, 2 Alfred Road, Kennebunk, ME 04043; 1-207-985-3111. Alengo Nyamay’antu is a scientific communication specialist, and Cassie-Marie Peigné is a scientific support specialist at Polyplus-transfection SA, 75 Rue Marguerite Perey, 67400 Illkirch-Graffenstaden, France; 33-3-90-40-61-80.

CellCUBE, CellBIND, CellSTACK, and HYPERStack are registered trademarks of Corning Incorporated. PEIpro is a registered trademark of Polyplus-transfection.