Hybrid Design Considerations in Biomanufacturing: Leveraging Both Stainless-Steel and Single-Use SystemsHybrid Design Considerations in Biomanufacturing: Leveraging Both Stainless-Steel and Single-Use Systems

Demand for biopharmaceuticals is growing rapidly as new products and manufacturing technologies arise. For example, such approaches as immunooncotherapy and oncolytic viral therapy are now entering one of the fastest growing markets in medicine — cancer treatment. This market “should grow from [US]$177.4 billion in 2021 to $313.7 billion by 2026, at a compound annual growth rate (CAGR) of 12.1%” (1).

Demand for biopharmaceuticals is growing rapidly as new products and manufacturing technologies arise. For example, such approaches as immunooncotherapy and oncolytic viral therapy are now entering one of the fastest growing markets in medicine — cancer treatment. This market “should grow from [US]$177.4 billion in 2021 to $313.7 billion by 2026, at a compound annual growth rate (CAGR) of 12.1%” (1).

Both preclinical and final biomanufacturing increasingly incorporate single-use (SU) components, including hardware and systems for containment and connectivity. Solutions also are increasing for portable turn-key systems, dedicated software, and process support (2). SU materials are available for most biopharmaceutical operations because suppliers continually offer new products and applications (3).

Such work has expanded SU technologies into new product modalities, manufacturing formats, and automations. In fact, the SU bioprocessing market is expected to grow from $21.98 billion in 2021 to $84.12 billion by 2030, at a CAGR of 16.1% (4). Yet, because an entirely SU process flow is often either impossible or undesirable, many biopharmaceutical companies are establishing “hybrid” manufacturing facilities that leverage both SU and traditional stainless-steel systems.

Advantages of Single-Use Equipment

Initial investment costs for SU-equipped facilities often have been reported to be 50% lower than those for conventional facilities housing multiuse, stainless-steel (hereafter called durable) formats (2). The doubling in cost for stainless-steel stock between 2020 and 2023 will have significant implications for companies needing to select an equipment format.

Compared with durable equipment, SU systems present smaller physical and manufacturing footprints, and they are known to reduce costs, lead times, validation, and utilities demand in such steps as changeover, sterilization, cleaning, operation, and maintenance. The ability to close an open process through SU equipment can reduce segregation requirements and cleanroom classifications.

Time needed for setup, process validation, and turn-around is reduced, as well. Direct savings come from reductions in both personnel demands and use of such materials as purified water, cleaning chemicals, and energy for hot water and steam. As compared with facility designs based on durable equipment, SU facilities reportedly show a 46% decline in total water and energy consumption and a 35% more favorable CO2 balance (5). Additional savings can come from reduced need for process analytics, validation, documentation, and quality control between consecutive operations. Thus, SU systems can enhance plant productivity, lowering overall operating costs per batch.

Both rigid-support and plastic-product contact surfaces are regulatory compliant, qualified, and commercially available worldwide. The de novo design of a durable assembly is highly customizable and scalable. However, significant ad hoc changes in process, scale, or flowpath can be expensive and involve extended manufacturing shutdowns. Not only are SU systems highly configurable in their original designs, but their flowpaths and production modes are particularly alterable and scalable (within certain ranges) after initial implementation.

For example, adaptations of SU systems to perfusion and continuous manufacturing modes are much easier and less expensive than are changes to durable configurations. Such flexibility is enabled by the portability of SU systems’ rigid containment equipment, and many disposable components — and therefore process flowpaths — are produced on a design-to-order basis.

Thus, implementing skid-based and even wheel-mounted SU mixers, reactors, and automated cell processors becomes a low-cost activity without reducing immediate plant-capacity utilization. Additionally, SU adaptability, portability, and availability enable clonal replication of an operation or process in a distal facility, supporting distributed or in-country manufacturing.

Because a SU-product flowpath is discarded and replaced after each batch, risks for adventitious agents and cross-contamination between batches (of the same product or of different products) are nearly eliminated. That feature benefits both manufacturing and patient safety as well as assisting in compliance with such directives as the latest revision of the European Medicines Agency’s (EMA) and Pharmaceutical Inspection Convention and Pharmaceutical Inspection Co-Operation Scheme’s (PIC/S) Annex 1 guidance.

SU systems can support manufacturing of multiple products within a given site or manufacturing suite, whether concurrently in separate bioreactors or sequentially within the same bioreactor structure. Because many biomanufacturers are intensifying processes and improving controls for their current SU systems, the ease of ordering modified SU ports, sampling mechanisms, and adjunct equipment also has become an advantage.

Discarded SU materials are a highly visible environmental burden (6). Counterintuitively, however, life-cycle assessment (LCA) and other science-based approaches have determined that the overall environmental sustainability of SU systems is often better than that of durable alternatives. Furthermore, disposable equipment can be incinerated easily or even recycled (7).

Significant variety among SU products and vendors provides multiple opportunities for selecting systems that best address a user’s design criteria. Industry suppliers now are supporting mid- and downstream operations with the release of SU prepacked chromatography cartridges, filtration units, pumps, centrifuges, heat exchangers, membrane adsorbers, tangential-flow filtration systems, and perfusion-supporting devices.

Because custom-designed SU flowpaths come presterilized, they support small-scale, closed, and/or automated processing of many emerging drugs, including advanced-therapy medicinal products (ATMPs), personalized medicines, and biotherapies for rare diseases. The ability to close a process through SU equipment is also important for working with hazardous materials. Functional ribonuclease (RNase)–free SU assemblies also present particular benefits for manufacturing RNA-based drug substances.

Obstacles to SU Implementation

Commercial Concerns: A primary difficulty for SU manufacturing lies in large-volume applications. Disposable systems cannot address significant production demand with high facility use over several years. Such limitations increase the relative economy of large-scale durable systems. Engineering concerns also limit SU scalability. Whereas durable mixers, bioreactors, and fermentors can be constructed to hold tens of thousands of liters, commercially available SU systems can provide about one-tenth of that capacity.

Although capacity is growing among some SU systems, practical limits remain for some operations because of the material sensitivity and installation logistics associated with assembling disposable components. For instance, the weight of such components can raise complexities, especially after use. Thus, many commercial suppliers have limited the sizes of their mixers and bioreactors to 2,000 L.

Some operations and skids are easier to transition to SU formats than others. Bioreactors, mixing systems, and connectors tend to be rather straightforward conversions. Heat-exchange, perfusion, and chromatography devices have been more challenging to translate, but vendors continue to provide solutions to many such difficulties, including obstacles to process monitoring.

The rapid evolution of biological products (e.g., ATMPs and novel vaccines) and associated manufacturing processes has introduced another difficulty. Although fit-for-purpose SU technologies are being developed for some new products and processes, shortages continue for other cases requiring process-specific solutions. The lack of specialized systems is causing many manufacturers to patch together technologies designed for traditional protein biologics or the medical-devices field. Because such systems were designed for considerably different workflows, they might not work optimally for new applications, therefore leading to inefficient and expensive processing.

Because of technical or financial limitations, commercially available SU systems simply cannot support some manufacturing processes. Many operations for biopharmaceutical product and intermediate manufacturing involve aqueous-based activities at standard temperatures and pressures. However, products such as oligonucleotide therapies can require, e.g., work with organic solvents and high-pressure microfluidizers. Specialized upstream processes and many downstream chromatography operations have yet to undergo widespread conversion to SU formats. But new and exciting solutions continue to appear (8).

Supply Chains for Disposable Components: The rapid growth in the demand for SU products observed over the past few years has many origins, including the sudden emergence of SARS-CoV-2 and the subsequent need to manufacture COVID-19 vaccines and treatments. Manufacturers of SU consumables, therefore, are experiencing difficulties with capacity and timely procurement of some high-purity polymers that serve as raw materials. Those and other constraints are causing supply-chain issues such as long lead times for both SU equipment and their consumables. Hence, the industry has entered an “SU supply crunch,” as evinced by 50% of participants in recent BioPlan Associates analyses of biomanufacturing capacity (2, 9). Survey respondents reported lead times of over one year for some consumables.

Many SU systems impose single-source supply chains upon their users, diminishing the industry’s ability to find solutions to the supply crunch. Commercially available SU systems often do not integrate with other brands or their components, and many users have called for increased standardization in the shape, porting, and mixing configuration of consumable components to help establish multivendor supply chains (10). Stockpiling SU consumables in anticipation of troubled supplies can lead to expiration of unused materials, contributing to operational, financial, and environmental burdens.

In the meantime, many end users have decided to implement combinations of systems from different suppliers to establish secondary sources for consumables. Troublesome issues here include complexities in assay, validation, and inventory processes; costs from SU extractables/leachables studies; and the need for comparative fit-for-purpose studies — as well as source-specific training requirements and risks of operator setup error.

Although SU facility designs significantly reduce some build and other capital costs, SU operations inherently require incrementally more warehousing space and inventory management for consumable components. Designing for inventory from multiple suppliers or in anticipation of supply interruptions only exacerbates that concern.

Sustainability: Many comprehensive LCA-based reports conclude that SU systems can be more sustainable than their durable counterparts; however, other considerations arise (11, 12). For some products, scales, and geographical settings, durable systems contribute fewer environmental burdens than do SU technologies. SU also generates a significant, visible amount of plastic waste, and as facility energy consumption and water service become “greener,” the relative environmental advantages of SU are reduced (13, 14).

When considering the environmental burdens of disposable materials in SU manufacturing, we must consider not only the mass of the product-contact plastic itself, but also the materials involved in packaging and transportation — as well as the burdens from postuse transportation and recycling activities. Issues such as plastic waste and concern over extractables/leachables restrict the growth of SU in some settings (5, 7).

Hybrid Systems

Biologics manufacturers need flexibility to respond to evolving market and technology trends, support portfolio diversity, and manufacture at different scales and durations. Establishing a hybrid facility can help to address such imperatives.

Not even state-of-the-art SU facilities that manufacture biologics at scale use disposable equipment only, and nearly all durable-manufacturing sites use some disposable supplies. From one perspective, all biomanufacturing facilities are hybrid. But we consider a hybrid facility to be one that leverages both SU and durable technologies as operational systems in the same suite or building layout.

Hybrid processing exists in three ways, each with distinct features and operational contingencies. A facility can contain

• some SU and some durable process trains

• process trains composed of both SU and durable-based operations

• processes containing some of the same operations duplicated in both SU and durable equipment.

Many of the features and drawbacks to SU and durable systems that we mentioned above will be present in a hybrid operation. However, a hybrid facility can establish new advantages and burdens. One obvious incremental burden is that if both SU and durable versions of a particular operation exist, then they will need distinct protocols. Other concerns involve the required dual sourcing of process and maintenance materials, suite service, and quality and regulatory functions required by each technology type. However, the operational flexibility and security associated with maintaining both formats can make a hybrid setup a prudent choice nevertheless (15, 16).

We have reviewed the merits of both SU and durable systems above, and how such systems might fit into a facility design obviously will follow the number, type, timing, and manufacturing scale of products that will be handled at the site. A major advantage in a hybrid setup is the ability to support either known or potential diversity in products, processes, and scheduling. Contract manufacturers especially have implicit unknowns in the types of products, operations, and chemistries that they will address. They, therefore, have an inherent use for the chemistries, process flexibility, and changeover speed that a hybrid design affords.

Novel and current state-of-the-art operations can guide biomanufacturers to a hybrid process flow. For example, it is common for a well-understood SU seed reactor (N – x) to feed a cost-efficient and large-scale durable production reactor. The evolution of conventional manufacturing processes, such as the adoption of perfusion-based continuous modes and highly automated SU-based skids, can impose a need to perform both durable and SU processing.

Different products addressing the same indication — and even products that leverage similar manufacturing platforms — can be produced through significantly different operations and processes. For protein biologics, Pichia pastoris, Escherichia coli, and other promising platforms could improve process efficiency. The emergence of allogeneic-based approaches to some ATMPs is creating uncertainty about future manufacturing systems, as is a growing debate about centralized versus local manufacturing. Autologous therapy is currently more advanced and more often entertained by ATMP developers, yet for many treatments, an allogeneic strategy promises to be a better ultimate solution. The increased simplicity, economy, and availability of automation in cell therapy are driving consideration of point-of-care processing (17). Such developments highlight the values in hybrid process designs.

Sustainability dynamics, of course, come into play with hybrid formats. For example, installing a photovoltaic power supply on site or “greening” the local energy grid can help to balance the relative environmental impacts of, e.g., clean-/steam-in-place (CIP/SIP) requirements for durable processing and disposable consumables in SU processing. Reprioritizing plastic-waste burdens over water fouling and eutrophication can alter priorities in alternatives, as well.

Finally, establishing hybrid operations can bring direct financial value. For instance, a hybrid setup represents an intermediate state of equipment depreciation between the high capital expenses of durable equipment and the high operating expenses associated with SU materials.

Hybrid Facility Design

Biomanufacturers can take many routes to arrive at a hybrid facility. Some companies undertake a gradual evolution away from durable equipment simply by installing individual pieces of SU equipment as they become available or desirable. For other manufacturers, a hybrid facility is the result of considering the values and costs of different options when addressing a specific process-development or expansion project (18). In other cases, when designing a building, suite, or process train, some companies comprehensively examine many parameters of existing systems and their operation using multifactor rational design and building information modeling (BIM).

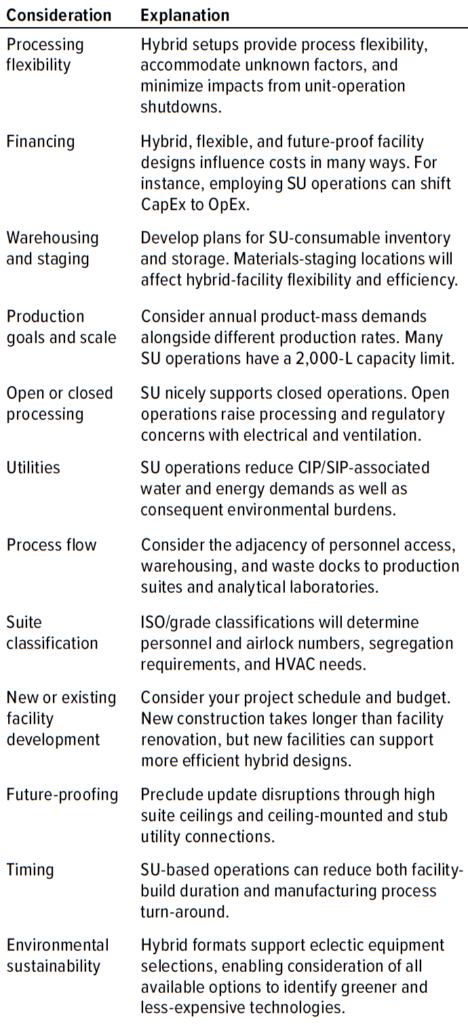

Quality by design (QbD) and science-based approaches are inspiring critical and rigorous consideration of suite designs, processing modes, and equipment to be implemented in an operation. A hybrid paradigm can enable an unincumbered, eclectic selection of equipment presenting the most economical, efficient, customizable, and sustainable features. When comparing build costs with operating costs, product quality, and personnel expertise, a hybrid design also supports consideration of all available automation technologies, their connectability with other equipment, and their ease of prequalification and validation. Table 1 summarizes primary considerations for facility design and how hybrid formats can affect them.

Table 1: Considerations for hybrid facility design (SU = single-use, CapEx = capital expenditure, OpEx = operating expenses, CIP/SIP = clean-/steam-in-place, ISO = International Organization for Standardization, HVAC = heating, ventilation, and air conditioning).

Design for hybrid facilities generally follows a melding of that for SU and durable equipment formats (19). Facility layout, suite configuration, service design, and automation strategies are dictated by the requisite platform and process flow as well as the manufacturing mode and associated equipment. Hybrid suites enable future-proofing through the ease and speed with which modifications can be implemented. The design process begins with defining production volumes and process conditions required for each manufacturing step. Then, the values, limitations, and service and materials requirements presented by SU and durable equipment can be evaluated. Final determination involves such parameters as suite classification, connectivity, automation, and required footprint (20, 21).

More specific design considerations include the location of staging areas for buffer preparation supporting classified manufacturing space. Such design can streamline both turnover times and SU/durable-mode harmonization. Ceiling-mounted panels for electrical and utility connections can provide flexibility to address the needs of both system types. Designing a facility for anticipated SU implementation while initially installing durable systems, or vice versa, enables facility future-proofing.

Growing Consideration for the Hybrid Paradigm

The number of applications continues to grow in biomanufacturing. The same is true for SU systems. However, conventional durable systems still offer distinct advantages for certain biological products, processes, manufacturing locations, and business goals. The use of hybrid process trains and facilities is growing because of the paradigm’s financial and operational advantages, with nearly a doubling of biomanufacturers intent upon including durable operations (2).

References

1 2021 Pharmaceuticals Research Review. Research and Markets, March 2022; https://www.researchandmarkets.com/reports/5555952/2021-pharmaceuticals-research-review.

2 Langer ES, et al. 18th Annual Report and Survey of Biopharmaceutical Manufacturing Capacity and Production. BioPlan Associates: Rockville, MD, 2021; https://www.bioplanassociates.com/18th.

3 Single-Use Bioprocessing Market Size, Share, and Trends Analysis Report by Product (Probes and Sensors, Simple and Peripheral Elements), By Workflow (Downstream, Upstream), By End-Use, By Region, and Segment Forecasts, 2021–2028. Grandview Research: San Francisco, CA, May 2021; https://www.grandviewresearch.com/press-release/global-single-use-bioprocessing-market.

4 Single-Use Bioprocessing Market (By Product: Filtration Assemblies, Disposable Bioreactors, Disposable Mixers, Media Bags and Containers, and Others; By Application: Filtration, Purification, Cell Culture, and Others; By End User: Biopharmaceutical Manufacturers, Clinical and Academic Research Institutes, and Others) — Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2021–2030. Precedence Research: Ottawa, ON, Canada, October 2021; https://www.biospace.com/article/single-use-bioprocessing-market-to-hit-us-84-12-bn-by-2030.

5 Barbaroux M, et al. The Green Imperative, Part Two: Engineering for Sustainability in Single-Use Technologies. BioProcess Int. 19(1–2) 2021: 18–25; https://bioprocessintl.com/manufacturing/single-use/the-green-imperative-part-two-engineering-for-the-new-plastics-economy-and-sustainability-in-single-use-technologies.

6 BioPhorum Environmental Sustainability Roadmap, 2022. BioPhorum: Sheffield, UK, 16 December 2022; https://doi.org/10.46220/2022SUST001.

7 Whitford W, et al. The Green Imperative, Part Three: Postuse Management of Single-Use Bioprocessing Materials, Today and Tomorrow. BioProcess Int. 19(11–22) 2021: 12–18; https://bioprocessintl.com/manufacturing/single-use/the-green-imperative-part-3-single-use-bioprocess-materials-postuse.

8 The PAK System Continuous Manufacturing Equipment. PAK BioSolutions: Vienna, VA, 2023; https://www.pakbiosolutions.com/the-pak-system.

9 Rader RA, Langer ES, Jhamb K. COVID-19 Impact on Bioprocessing: Accelerating Trends and Long-Term Impact of Novel Coronavirus-19 on Biomanufacturing and Bioprocess Supply Chain. BioPlan Associates: Rockville, MD, June 2020; https://bioplanassociates.com/wp-content/uploads/2020/07/Covid-19-Impact-on-Bioprocessing-White-Paper-BioPlan-20200605.pdf.

10 Paldus BA, et al. Single-Use/Disposables Technologies and Equipment Roundtable. Amer. Pharm. Rev. 31 March 2016; https://www.americanpharmaceuticalreview.com/Featured-Articles/184450-Single-Use-Disposables-Technologies-and-Equipment-Roundtable.

11 Whitford WG, Petrich MA, Flanagan WP. Environmental Impacts of Single-Use Systems. Single-Use Technology in Biopharmaceutical Manufacture (Second Edition). Eibl R, Eibl D, Eds. Wiley: Hoboken, NJ, 2019: 169–179; https://doi.org/10.1002/9781119477891.ch13.

12 Budzinski K, et al. Streamlined Life Cycle Assessment of Single Use Technologies in Biopharmaceutical Manufacture. New Biotechnol. 68, May 2022: 28–36; https://doi.org/10.1016/j.nbt.2022.01.002.

13 Barbaroux M, et al. The Green Imperative, Part One: Life-Cycle Assessment and Sustainability for Single-Use Technologies in the Biopharmaceutical Industry. BioProcess Int. 18(6) 2020: 12–19; https://bioprocessintl.com/manufacturing/single-use/the-green-imperative-part-one-life-cycle-assessment-postuse-processing-and-sustainability-for-single-use-technologies-in-the-biopharmaceutical-industry.

14 Single-Use and Sustainability: How Single-Use Products Reduce Your Environmental Impact. Cytiva, 2023; https://www.cytivalifesciences.com/en/us/solutions/bioprocessing/knowledge-center/single-use-and-sustainability.

15 Hybrid Facilities Provide Necessary Flexibility to Biologics Manufacturing. Alicat Scientific, 2023; https://www.alicat.com/advantages-of-hybrid-equipment-in-biologics-manufacturing.

16 The Advantages of Hybrid Equipment in Biologics Manufacturing. Alicat Scientific, 2023; https://www.alicat.com/advantages-of-hybrid-equipment-in-biologics-manufacturing.

17 Automated and Closed Cell Therapy Processing Systems Market Outlook, 2022–2032. Future Market Insights: Newark, DE, December 2022; https://www.futuremarketinsights.com/reports/automated-and-closed-cell-therapy-processing-systems-market.

18 Nivsarkar H. Single-Use Versus Stainless-Steel Bioreactors: Choosing Which Is Best. Euro. Pharm. Manufacturer 4 August 2022; https://pharmaceuticalmanufacturer.media/pharmaceutical-industry-insights/biopharma-news/single-use-vs-stainless-steel-bioreactors-which-to-choose.

19 Bohn E. Facility Design Issues for Single-Use Processes. Pharm. Technol. 41(6) 2017: 42–43; https://www.pharmtech.com/view/facility-design-issues-single-use-processes.

20 Hybrid Bioprocessing: A Q&A with Andrew Sinclair. BioPharm Int. 28 June 2017; http://www.processdevelopmentforum.com/articles/hybrid-bioprocessing-a-qa-with-andrew-sinclair.

21 Genest P, John J. Designing a Biomanufacturing Facility Incorporating Single-Use Technologies. BioPharm Int. 29(5) 2016: 20–23; https://www.biopharminternational.com/view/designing-biomanufacturing-facility-incorporating-single-use-technologies-1.

Corresponding author and BPI editorial advisor William G. Whitford is life sciences strategic solutions leader, and Paul Szafir is lead project architect, both at Arcadis DPS Group; [email protected]; https://www.dpsgroupglobal.com.

You May Also Like