Audience:

the key element behind all style and content decisions in any spoken or written material. When publications existed only in print, audience-related criteria were easier to maintain than they are these days. Bound periodicals lived in libraries sequestered by subject. Unless you knew where “your” material lived, you were unlikely to stumble upon it — but information could get lost. Manual crossreferencing wasn’t easy, and I would not want to return to the days before powerful Internet search engines! But now, readers often are directed to materials for which they themselves are not the primary audience.

Audience considerations can drive editors nuts: Will academic readers be upset by the promotional appearance of trademark symbols? Will supplier authors be upset when we (by policy) leave registration marks out? Will engineers recognize the meanings of acronyms from microbiologists? Will the passive voice favored in laboratory notebooks be appropriate for readers from different disciplines?

The n...

Jupiter images (www.graphics.com) REPRINT WITH PERMISSION ONLY

Infectious Agents: A Global Effort

Worldwide Commitment to Fight Antimicrobial Resistance:

Medical, business, and government officials from around the world gathered in Amsterdam for the ECCMID 2016 Conference in April 2016. Hosted by the European Society of Clinical Microbiology and Infectious Diseases (ESCMID), the meeting reinforced its attendees’ commitment to fight antimicrobial resistance in a concerted effort.

During an interactive session hosted by ESCMID and the Netherlands Society of Medical Microbiology (NVMM), researchers and representatives of the Dutch healthcare administration recommended introducing antibiotic stewardship programs, higher funding of research, and more international collaboration into antimicrobial therapies. They also recommend preventing the spread of infections through better surveillance, vaccination, and public education. Medical professionals need to set clear and binding goals and to continue sharing bes...

Concept of attack. Bacteriophage are viruses (with genetic material) that infect bacteria.

Bacteriophages are viruses (consisting of a genome contained within a protein coat) that specifically infect bacteria. They are the most abundant living entities on earth — the estimates range from 10

30

to 10

32

in total — and play key roles in regulating the microbial balance in every ecosystem where that has been explored (

1

). Bacteriophages are genotypic and phenotypically different from viruses that infect Archaea (Archaeovirus) and Eukarya (Eukaryovirus). The name

bacteriovirus

has been proposed as scientifically more accurate (

2

). Bacteriophage classification has been assigned to the International Committee for Taxonomy of Viruses (ICTV). It organized bacteriophages into 13 different families of the Caudovirales order (

3

).

Once a bacteriophage encounters a target bacterium, the process of bacteriophage replication takes place. The bacteriophage adsorbs and ligates to the bacterial membrane surface r...

P. GINTER, SARTORIUS STEDIM BIOTECH (WWW.SARTORIUS.COM)

Implementation of single-use technology in the biotechnology industry is increasing every year. One major interest has been understanding the interaction of extractables with protein and cells for applications ranging from cell banking to biopharmaceutical manufacturing. In October 2015, the Engineering Conference International (ECI) organization hosted a conference in Leesburg, VA, to explore how the science of plastic applies to bioprocessing. The “Single-Use Technologies: Bridging Polymer Science to Biotechnology Applications” meeting brought together experts from different fields to share issues, understanding, and solutions. About 100 attendees representing end users, academia, and suppliers (e.g, resin, film and single-use components fabricators) participated in scientific and collaborative discussions regarding the use of disposables for different functional areas. Those discussions led to appreciation for each other’s challenges and requireme...

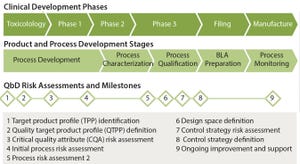

The quality by design (QbD) modernized approach to pharmaceutical development is intended to provide regulatory flexibility, increased development and manufacturing efficiency, and greater room to innovate as well as improve manufacturing processes within defined ranges without obtaining regulatory approval first. QbD is a systematic developmental approach that starts with a clear goal in mind and emphasizes understanding of how variability in both process and materials affects a final product (

1

).

Historically, product quality has been assured either with end-product testing (drug products) or with strict and narrow control of manufacturing processes without a comprehensive understanding of how process parameters link to product quality attributes (biologics). According to a 2011 US FDA guidance, product quality cannot be assured by testing alone (

2

). In the QbD paradigm, quality is built into the process rather than being “tested into” a drug product. Part 1 of this two-part article will address the...

BRISTOL-MYERS SQUIBB (WWW.BMS.COM)

Osmolality is a critical attribute for injectable formulations. It is desirable to have products match physiological osmotic conditions. Furthermore, osmolality provides confirmation of soluble content in solution. Preventing injection of hypo- or hyperosmotic solutions is a key element of parenteral formulation development. Additionally, some investigators have explored correlations between injection pain and formulation osmolality, although no significant correlation has yet been observed (

1

–

4

).

Osmolality is a valuable in-process test also because it provides a reliable and repeatable value that reflects overall solute content of a formulation. It is particularly useful to detect deviations in compounding when excipients such as stabilizing and tonicity modifying sugars, viscosity modifiers, and buffers are used at relatively high concentrations. Similarly, when the Donnan effect is present during ultrafiltration/diafiltration processes, osmolality is a good indic...

The Zetasizer Helix system combines Raman spectroscopy with dynamic light scattering. MALVERN INSTRUMENTS (WWW.MALVERN.COM)

Biophysical characterization has drawn great attention from the biopharmaceutical industry and regulatory agencies across the globe, especially for use in biosimilar drug product development. Currently available biophysical characterization tools can help in screening and optimizing better (more stable) formulations for such products. However, most tools cannot be used for head-to-head comparison of the biophysical properties of an optimized biosimilar formulation with those of an innovator product at higher concentrations.

We developed and optimized a formulation for monoclonal antibody MAb B (a biosimilar product to innovator product MAb A) in an iterative way by using typical biophysical tools — dynamic light scattering (DLS), evaporative light scattering (ELS), and differential scanning calorimetry (DSC) — with traditional antibody stability assessment tools: size-exclusion chrom...

Photo 1: Merck manufacturing site in West Point, PA

Single-use components have been successfully incorporated into many unit operations for both upstream and downstream processing, from laboratory scale to commercial manufacturing. The development of single-use filling needles has created an opportunity to introduce fully disposable systems into final formulation and filling of drug products (

1

). One major challenge in replacing a cleanable filling line containing stainless steel needles is to ensure that an alternative system can satisfy all critical performance parameters established for an existing process.

In 2012, Merck & Co., Inc. (Kenilworth, NJ) chartered a capital project to replace an existing syringe-filling machine in its clinical manufacturing facilities for finished drug products based in West Point, PA (Photo 1). As part of this project, capability was also added to use a single-use filling wetted path, including single-use needles. Here, we detail the management of this project from its ...

The biosimilars market is rapidly evolving, with more than 450 biosimilar molecules in development worldwide, and many anticipated transfers of molecules in process around the globe. With US$85 billion of biopharmaceutical products coming off patent by 2020 (

1

), the driving force to develop biosimilars is strong. The market will be highly saturated, with dozens of biosimilars currently in development for each current blockbuster molecule. We know of 46 trastuzumab biosimilars and 39 rituximab biosimilars in development. Because the biosimilars market is projected to be a commoditized one (with multiple entrants in most regions), it will be very cost competitive.

Current Biosimilars Market

Costs and Pricing:

Deep discounting already has been part of the market. Norway’s price regulator has been offered a 72% discount on biosimilar Remsima infliximab (produced by Celltrion and licensed by Orion Pharma) for 2015–2016. Previously, Hospira had offered a price discount of 51% off Remicade infliximab pricing ...

with Dr. Josefina Nilsson

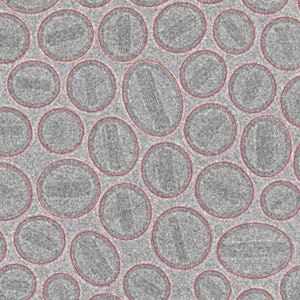

For this webcast, Josefina Nilsson (EM Services business unit head) discussed Vironova’s work, including case studies. She focused on characterization of drug and gene delivery platforms with electron microscopy and image analysis, specifically for systems that use viral vectors or liposomes. Along with two colleagues — Gustaf Kylberg (image analysis expert) and Mathieu Colomb-Delsuc (electron microscopist) — she then answered questions from the audience.

Nilsson’s Presentation

Structural characterization provides important insights into the quality of development and manufacturing practices, including encapsulating systems. Important characteristics include morphology, integrity, sample purity, and the ratio between filled and empty particles. Our analysis can measure unique parameters specific to certain delivery systems such as lipid-based and viral vectors. Using electron microscopy and image analysis, you can gain objective, repeatable, and quantitative structural informatio...

Biopharmaceutical manufacturers are increasingly investigating or implementing continuous processes, and industry experts are participating in vibrant and healthy discussions on a wide range of process approaches being adopted. We seem to have entered a phase within the biopharmaceutical industry (which is often described as conservative) of intense bioprocess innovation as manufacturers strive to lower costs and provide agile, responsive supply chains for “drug on demand” continuous manufacturing operations. Senior industry leaders met in Berkeley, CA, in late 2015 at ECI’s Integrated Continuous Biomanufacturing Conference II to hear keynote presentations from both Alison Moore (senior vice president of process development at Amgen) and Janet Woodcock (director of the Center for Drug Evaluation and Research, CDER, at the US Food and Drug Administration) and discuss real-world challenges of implementing continuous biomanufacturing.

Keynote Presentations Moore described Amgen’s target of achieving a proces...