IBC’s BioProcess International Conference and Exposition (BPI) is the largest bioprocessing event currently offered to our industry, bringing you new ideas, demystifying technology, and fostering partnerships in highly engaging formats to move drug candidates closer to approval. This year’s event will be held 26–29 October 2015 at the Hynes Convention Center in Boston, MA.

BPI is engineered to be exactly what you need it to be. Formal and informal networking experiences connect you to peers, prospects, and customers. Parallel tracks give you the option to dive deep or take a big-picture approach to learn about industry trends and challenges and benchmark them against the latest research developments. Big pharma and large, mid-size, and emerging biotechnology companies collaborating with solution providers featuring proven and next generation technologies make BPI a one-of-a-kind meeting place.

More than 1,600 bioprocess professionals from around the globe attend BPI each year to learn about leading strate...

BIOGEN IDEC WWW.BIOGENIDEC.COM

What’s on the minds of groups involved in cell culture and fermentation in 2015? They’re looking to implement genomics and other “-omics” technologies in cell-line development and engineering. They’re working with new analytical tools to model, monitor, and control upstream production bioprocesses. Many are interested in the possibilities of perfusion and other continuous processes. They want the most sophisticated single-use options developed with modern bioprocessing in mind. They’re adapting cell culture knowledge to new product modalities and applying all this knowledge toward improvements in efficiency, productivity, and development speed. And they’re increasing their understanding of how process conditions affect product quality.

Lately, we’ve been hearing a lot of grumbling about a lack of innovation in bioprocess technology. But over the past few years, BPI has published the work of several authors who would beg to differ. For instance, a September 2014 supplement sp...

BIOGEN IDEC (WWW.BIOGENIDEC.CO.UK)

During the past decade, biomanufacturers have faced increasing bottlenecks, process times, and operation costs in their downstream processing. That has led many companies to reevaluate their traditional methods and technologies and consider replacing or supplementing them with strategies for reducing the number of purification steps and leveraging more efficient, less expensive, and well- understood approaches.

Some strategies to enhance efficiency have focused on optimizing recovery and initial clarification processes, especially when removing host-cell proteins (HCPs). Although HCPs are an essential component of the growth and survival of normal cellular processes, the presence of residual HCPs can pose safety risks for drug products. Part of the problem manufacturers are having with clearing HCPs is the difficulty in identifying them. This year’s BPI Conference and Exhibition will feature some presentations dedicated to handling that task, including the use of mass sp...

BRISTOL-MYERS SQUIBB (WWW.BMS.COM)

Biomanufacturers are striving for leaner and more flexible processing, and it’s paying off. Reports received at BPI are showing that companies are improving the efficiency and robustness of their processes, and some are making changes in facility and process designs. Multiproduct, closed-system, and “portable” manufacturing facilities are helping manufacturers meet capacity demands. And additional competition from biosimilars makers has pushed some companies toward further expanding their commercial market as their original biologics come off patent.

Contract manufacturing in general is growing, thereby allowing some biomanufacturers to focus on more innovations. That trend is driving emphasis on good technology transfer and the criticality of selecting a “right- fit” contract manufacturing organization (CMO), as presented in the discussions below.

But challenges remain. Risk management requires considering the entire life cycle of a drug product. And the developability ...

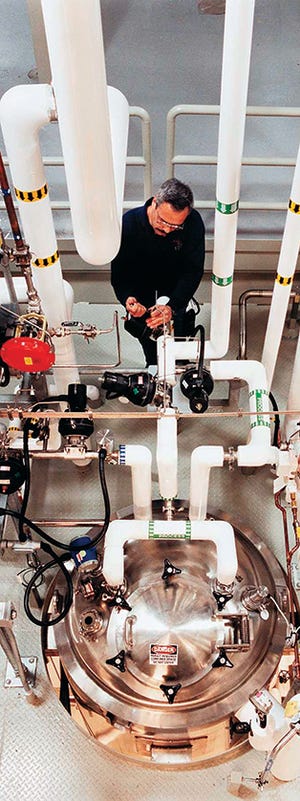

WWW.PHOTOS.COM

What’s on the minds of groups involved in drug-product manufacturing in 2015? They’re applying quality by design (QbD) principles and process analytical technology (PAT) to formulation and fill–finish. High- throughput and single-use technologies are helping them improve process economics as well as sterility and flexibility. Formulators are redrawing the lines between drug substance and drug product manufacturing, especially when it comes to preformulation analysis. Fill–finish groups are working out the details of new types of container– closures and delivery devices. They all share case studies to help one another solve similar problems. And they’re applying lessons learned so far to develop biosimilars and new product modalities.

Biologics manufacturing can be thought of as a continuum, but divided into discrete wavelengths (areas of expertise) along that spectrum: from production of the active molecule upstream to purification of it downstream to formulation and packaging of that drug ...