A Biotechnology Powerhouse That's Always Thinking AheadA Biotechnology Powerhouse That's Always Thinking Ahead

July 1, 2008

Figure 1.

AmProtein Corporation is a biotechnology powerhouse that has revolutionized the biologics industry with the discovery of a novel expression vector and development of a disposable bioreactor series. AmProtein has used these two discoveries to develop an unbelievably simple and efficient, industrialized CHO cell protein production platform. This platform includes a revolutionary expression vector; a single-use, plastic bag-based bioreactor system based on a novel, patented O2 transfer method; and serum-free cell culture media. The platform is scalable from bench to manufacturing, and our bioreactor system makes current bioreactors utterly obsolete. AmProtein currently uses this platform in its contract manufacturing business, which is especially suited for production of difficult-to-express proteins. AmProtein is successfully applying its vector and manufacturing platform to plant, insect, yeast, chicken, and fish cells.

AmProtein is open to fostering partnerships around the globe for the codevelopment of its technologies. Currently, we enjoy fruitful collaborations in China and the United States. In addition to our Chinese campus, our partners include Harbin Bioengineering Corporation, North China Pharmaceutical Corporation R&D Center, and Xian drug evaluation Center. In the United States, AmProtein is a member of the California Biotechnology research Consortium.

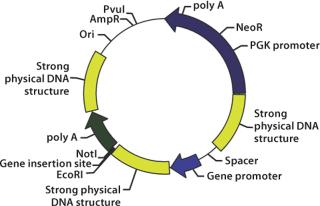

Revolutionary Vector Series

The development of the CHO dhfr- cell lines to increase expression titers was the first revolution in mammalian gene expression to transform research into a commercial process. However, with it came a tedious and costly cell-clone screening process. Our vector has surpassed current expression technologies by delivering commercial-level protein titers after several stable gene transfections. This is the second revolution in mammalian gene expression. Currently working in mammalian cells, our expression vector is believed to act through a common mechanism for possibly all eukaryotic gene expression. Highlights of AmProtein’s expression vectors include

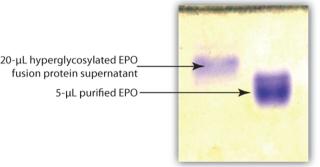

Clear signals visible by dot blot from 96-well plates only three hours after change into serum-free suspension culture media; after only 24 hours, you can stain the protein directly from culture media (Figure 1)

Extremely high protein expression (50–120 pg/cell/day) directly after several stable gene transfections in almost all protein (including traditionally difficult to express proteins) and antibody projects in CHO cells

One-time commercial-level high protein expression in mammalian cells is no longer a problem; robust mammalian host cell lines are needed immediately to match this expression technology.

Figure 1. ()

Figure 2. ()

This expression technology places your protein or antibody project immediately into a stage of commercial cell clone robustness screening in a serum-free suspension environment and bypasses the stage of labor-intensive and costly high-titer expression screening.

Novel Oxygen Transfer Method

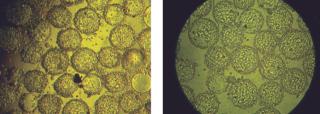

The mechanism of oxygen transfer uses a current of culture medium sweeping along a certain air-exposed smooth-surfaced material with a certain force creating microscopic bubbles and transforming air O2 into dissolved O2, which is defined as microscopic bubbles in between water molecules. Based on this patented, novel O2 transfer method, AmProtein’s bioreactors provide an ideal environment for extremely high-density suspension cell cultures. The simple O2 transfer method gives the CURRENT bioreactor line beneficial characteristics including impeller-free mixing and sparge-free oxygen transfer. This results in zero cell death due to bubble-burst or shear force. Our bioreactors typically reach a packed cell volume of 5–7%.

Incorporating a frustoconical bottom, our bags have been designed from start to finish to prevent deadly and unnecessary mechanical forces on the cells. AmProtein uses a novel material that is ideal for more efficient O2 transfer. The bags include a simple and reliable single-use sampling system, and they can be custom designed for specific applications, including GMP production. In an effort to limit the impact on the environment, we are also working on biodegradable plastic bags.

Currently, 40-mL, 150-mL, 1-L and 3-L miniature bioreactors for process optimization and seed trains are ready for use. Our 5-L, 50-L, and 150-L CURRENT bioreactors are also now available. A 300-L model is in development. Our CURRENT bioreactor can be directly transformed into a perfusion bioreactor by connecting it to a container full of carriers for cell attachment. The bioreactor then acts as a DO generator.

AmProtein also produces modified CURRENT high-speed rotating bioreactors for high-density carrier-attached cell culture. AmProtein’s high-speed rotating bioreactor has already proven to be more efficient in testing of multiple cultures of different cell types being engineered to manufacture vaccines. Microcarrier-attached VERO, MDCK, MRC-5, and CHO cells have already been successfully cultured at high densities in regulatory-friendly serum-free media.

Dual Functional Domain Abs

The next generation of therapeutics in the post-Ab era is likely to be dominated by dual-domain antibodies. The benefits of such proteins include synergy or additive action, and longer half-life. In addition, they have the potential to reduce the number of drugs to be taken by a patient. Compared with single-domain drugs, dual-domain drugs may be more effective for a specific disease than a single drug, have relatively simplified FDA filing, and have multiple clinical indications. AmProtein has recognized such benefits and is a pioneer in engineering dual-domain protein drugs.

We hold a global IP position that guarantees a freedom to operate, and based on our patents we have developed novel dual-domain drugs that have been validated in early animal studies. We have performed proof-of-concept studies in China. Currently, AmProtein is looking to codevelop its dual-domain protein drug candidates for autoimmune diseases, psoriasis, cancer metastasis, ischemic heart diseases, asthma, and diabesity (diabetes complicated with obesity). Among our pipeline of patented dual-domain combinations are IL-18bp-Fc-IL-1ra, IL-4R-Fc-IL-1ra, TNFRI-Fc-IL-1ra, Symlin-Fc-Leptin, PYY-Fc-Leptin, and GLP1-Fc-Leptin.

AmProtein’s Business Priorities

Difficult protein expression

Licensing out revolutionary vector series

Process development by using disposable bioreactor

From DNA to Kg protein

Preclinical evaluation

Biosimilar and enhanced bio-similar development

Codevelopment of dual-domain drugs

Figure 3. ()

Figure 4. ()

Table 1. Expression levels of nonconfidential projects in CHO K-S cells after stable gene transfection

REFERENCES

1.) Jia, Q. 2008. A Bioreactor System Based on a Novel oxygen transfer Method. BioProcess Int. 6:66-71.

You May Also Like