Anticipating Cell-Line Challenges to Drive CMC ReadinessAnticipating Cell-Line Challenges to Drive CMC Readiness

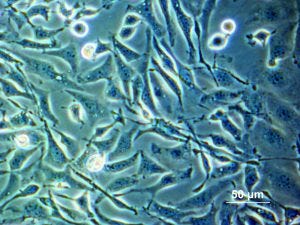

Phase-contrast microscopy image of Chinese hamster ovary (CHO) cells (https://en.wikipedia.org)

Development of a safe and high-quality Chinese hamster ovary (CHO) cell line is of paramount importance for the chemistry, manufacturing, and controls (CMC) portion of studies that support investigational new drug (IND) applications (1, 2). Desirable attributes of a CHO cell line include its ability to

produce high titers of biotherapeutic proteins

facilitate quick recoveries and selection processes

maintain phenotypic and genetic stability throughout in-vitro aging of a culture.

A CHO cell line also should be scalable to high-capacity culture processes and meet required testing standards (e.g., identity, absence of viral or mycoplasma contaminants, and so on).

The first three attributes above strongly depend on molecular characteristics of the expression vector, whose origin and methods of DNA preparation must be reported (3). The other two attributes arguably are influenced by laboratory-scale processes and controls incorporated during process design and qualification activities (4, 5).

Furthermore, experimental approaches are likely to change among monoclonal antibodies (MAbs), Fc-fusion proteins, bispecific antibodies, and other modalities. Biomanufacturers emphasize the listed attributes differently to align cell-line development (CLD) with the missions of their companies. Some biomanufacturers implement CLD to generate reference materials quickly to support the nomination of a development candidate (DC) molecule, and they choose to invest resources to maximize production titers.

Historical Background

A fundamental regulatory requirement is the traceability of parental CHO cell lines, including how they evolved from the original CHO cell line, which was isolated in 1957 by Theodore Puck (6). Decade after decade, different research laboratories have manipulated, genetically engineered, and treated the original CHO cell line with serums, supplements, and selective agents. During the 1960s and 1970s, the original CHO cell line was cultured at multiple research facilities, and variants started to arise (e.g., CHO-K1, CHO pro3-DHFR+, and others). Authenticated and quality-controlled CHO-K1 cell lines can be obtained from the European Collection of Authenticated Cell Cultures (ECACC catalog number 85051005), the American Type Culture Collection (ATCC CCL-61TM), and other organizations.

The 1980s and 1990s brought a surge in CHO mutagenesis work using gamma-ray irradiation (DUKX-B11, DG44) and other selection techniques (CHO-S). Commercial off-the-shelf CHO cell lines became available in the 2000s and 2010s with many vendors providing their own proprietary CHO variants, optimized cell-culture media, and specific technical protocols. Examples include K1-SV-GS-KO (Lonza), CellcaCHO (Sartorius), Potelligent (BioWa), CHOZN (MilliporeSigma), CHO-M (Selexis), Life Technologies’s ExpiCHO (Life Technologies, now Thermo Fisher Scientific), and HD-BIOP3 (Horizon Discovery) cell lines in rigorous chronological order.

Other research organizations now choose to use their own proprietary CHO-DG44 or CHO-K1 cell lines (a full list and recommendation falls outside the scope of this article). It is reasonable to anticipate the emergence of novel off-the-shelf CHO cell lines. Their creators could leverage genome editing mediated through clustered regularly interspaced short palindromic repeats (CRISPR), site-specific integration, transcription-factor engineering, and transcriptome regulation among other exciting current areas of development in CHO cell engineering.

CMC experts must work with technical development groups to determine whether animal serum has been used during CLD. Transmissible spongiform encephalopathies and/or bovine spongiform encephalopathy (TSE/BSE) absence or presence must be stated in a TSE/BSE risk-assessment document. That report also must describe the origin of each reagent and material ever to have come in contact with the cells. The Q5D guideline from the International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use (ICH) requires that the history of transfers, manipulation, and changes in the parental CHO cell line be traceable, clear, and recorded (7).

Establishing Cell Banks

In recent years, drug developers and contract manufacturing organizations (CMOs) have strived to establish early stage CHO pools in as rapidly as in two to three weeks. That work supports research and development activities, assays development, animal studies, and process development. Drug developers and CMOs also create a monoclonal cell line (clone) of single-cell origin to establish each master cell bank (MCB) while running processes that comply with good manufacturing practices (GMPs) and generating clinical trial materials (CTMs) (8).

Such concurrent activities can have a positive influence on the overall timeline from DC nomination to IND filing. Pooled cell lines are transfected and seeded either in bulk (millions of cells in milliliters of cell culture) or in minipools (thousands of cells in microliters of cell culture). Periodic medium replenishment is needed until cells recover. Bulk and minipools can have different cellular stabilities when appropriate combinations of vectors, stringency, selection, and screening are applied. Clones are established from a parental stable pool (three to four weeks after the pool is established), and their monoclonal origin is verified with high-resolution imaging, cell sorting, cell printing, and other techniques (9).

As a result of their single-cell monoclonal origin, clones are deemed to be more homogeneous and stable than pools. Because of inherent genomic plasticity, CHO cell lines (irrespective of their origin) can undergo spontaneous mutations and phenotypic changes (10). Thus, clonality might be secondary to phenotypic stability over generations, but the latter typically is determined through stability studies (in vitro cell aging) of 80 generations or more (11). The need to identify a stable pool and clone quickly has great CMC relevance because doing so enables selection of a lead cell line to continue upstream process development, MCB establishment, and testing.

An MCB must be characterized and qualified properly. That includes documenting starting materials, species of origin, history, identity testing, adventitious agents, mycoplasma, viruses, genetic profile, and others details that depend on the specific cellular source and nature of the biotherapy to be manufactured (1). A typical progenitor of an MCB is a research cell bank (RCB) of the selected clone, typically stored in a few vials at a development laboratory rather than a GMP suite.

For an RCB to be transferred to an GMP suite for developing an MCB, cell-line developers must have sterility information of that RCB. An accepted method is to use large-volume quantitative polymerase chain reaction (qPCR) for rapid detection in an RCB. Guidelines for mycoplasma testing in MCB, GMP intermediates, bulk harvest, and final product are specified to include agar, broth, and indicator cell lines (1).

Cell-line developers typically make a working cell bank (WCB) from a characterized MCB to ensure that they will have enough supply of starting cell material. When this common two-tiered approach is implemented, an extensive characterization of the parental MCB is recommended, but a WCB might be tested by focusing only on adventitious agents (12). Cell population doubling time should be comparable between an MCB and the derived WCB at this stage. If the MCB has not been characterized thoroughly, then biomanufacturers can perform such a characterization on the WCB used to produce each lot. Finally, biomanufacturers should characterize cells that are expanded to or beyond the end-of-production passage level (end-of-production cells, EoPC) to demonstrate stability of the cell substrate. Testing at this stage covers identity, mycoplasma, sterility, and genetic stability as well as the presence of adventitious agents and viruses (1, 12).

CMC Approaches

CMC mainly focuses on two specific areas pertaining the cell bank manufacturing, testing, and release: timelines and clinical operations and demand. First, timeline management ensures that MCB is established before the start of a toxicology batch and fully released by the time that a GMP process starts. Depending on the quality assurance risk tolerance and overall philosophy, the GMP process can be performed while some testing is ongoing. Second, establishment of a WCB and EoPCs as well as testing of genetic stability (typically performed before the start of pivotal trials) must be planned carefully with clinical-operations and clinical supply-chain groups to determine whether such activities are relevant to a specific program at a specific time. CMC typically is the key stakeholder for such activities and CMC teams bear the responsibility of setting strategies and carefully planning operations for program.

At the development-laboratory level, the grade of a cell line is determined by how homogeneous and stable a cell source material is. Good project and inventory management must be in place to ensure that the grade of a cell line and its expressed product will be consistent with the expectations at every step. That is important regardless of whether a cell line is an early pool, a pool deemed to be stable, a clone, or a clone in a final process and whether the cell substrate is pre-RCB, RCB, or MCB. Although an early stage pool is desirable for a quick assessment of a biotherapy’s potency, function, and product quality (PQ), it is not typically suitable for generating CTMs. But advancements in high-resolution analytical screening could allow that soon.

Assessment of Pool Material

Pools are heterogeneous groups of product-expressing cells in a culture. Each of those cells underwent different genetic-integration events during transfection, adapted at different paces to the selective medium, and proliferated at different growth rates. Hence, the PQ of pool material originates from a mix of different cells that have recovered independently. They might show differences at later generations as cells double at asymmetric rates.

Recent improvements in CLD techniques suggest that the phenotype and PQ of a pool can be matched reasonably well to those of a derived clone if high-resolution screening can demonstrate it (13). By that rationale, a clone can be plugged into a process established from a parental pool line. Such a staging strategy can save time, although CMC teams must balance the time investment accurately in matching a lead clone to the parental pool process with determining whether risks might arise (14). In general, acceleration strategies fit well for platform development of conventional MAbs, although they might not be ideal for complex molecules or specific quality target product profiles (QTPPs) (4).

A typical CMC question is “How soon is the cell line material deemed representative of the final material?” The answer is not trivial because it depends on the intended scope of that material. Developability assessment from pool material can point to molecule liabilities such as molecular-weight variants (e.g., aggregates or fragments), glycosylation (e.g., excessive mannose), and hot spots (e.g., deamidation or oxidation) (15). Product stability over time can be investigated after pooled bulk-harvest is processed. Those data can be used to select the specific purification scheme or formulation buffer for drug-substance and drug-product manufacturing (16). By the same rationale, stability under stress can be investigated (e.g., by conditions of temperature, pH, freeze–thaw cycle, and light). Pooled material can be used for nonclinical single-dose pharmacokinetics (PK) studies, preclinical assays (cytokine release), bioassays development (e.g., cell-based assays, potency, ADCC, and identity) (17). In such cases, pooled material could represent the final clone material, especially if the latter is formulated in a buffer that approximates to final CTM.

Biotherapeutics also can be expressed in transient mode using the same parental CHO line. However, this quick approach entails low-production titers and substantially different PQ from that of the CTM. Typically, a transient cell line is not cryopreserved, so multiple production runs are needed if material demand increases. It’s not uncommon to observe batch-to-batch variances, which indicate that the material source is not representative. For those reasons, transient expression is a valid strategy for large screening efforts (e.g., chimera or humanized-antibody-binding screens) but less desirable for studying manufacturability of a molecule (18). Future vector work is likely to expand the use of the same DNA constructs in both transient and stable integration modes, generating time savings and resource optimization during the transition from preclinical to IND-enabling studies.

One emerging concept in cell processing is determining how early a process can be established. A biomanufacturer can use a platform-based approach to develop a phase 1 process while setting tighter controls during phase 3 or commercial processes.

Pooled cells can be used to begin upstream and downstream activities with some assumptions. For example, you can investigate nutrients and gassing requirements in pools and reduce the time invested during development of a clone process (19).

Process-like feeding regimens can be scaled-down and tested once pools are established using a multivariate approach (20). Likewise, downstream purification on pool material can indicate what buffers or elution conditions are suitable for specific biotherapeutics and whether two or more purification steps will be necessary to achieve a sufficient level of purity.

Pooled material also is used to determine final formulation buffers and to understand the stability of a molecule before the official GMP stability testing. At the same time, a clone cell line can be established. All these strategies can expedite CMC development and increase the understanding of a molecule and its manufacturing process.

Increasing Production Titers

Through different production strategies, biopharmaceutical companies are producing titers >10 g/L — amounts that were barely conceivable just 10 years ago. Although such technical accomplishments are evidence of the industry’s investment in CLD and PD, we caution that titer is only one portion of CMC development.

Production titers must be contextualized with overall process recovery, overall process yield, and foreseeable clinical demand of a drug. Strong incentives exist for increasing production titers of established processes of blockbuster drugs. But that might not be the case for early phase processes of rare-disease and scarcely demanded drugs.

Making more protein than needed increases costs for disposing of unnecessary unprocessed bulk harvest, designing a downstream process for purifying large amounts of material, procuring large volumes of capture-step resin (an expensive reagent), and storing drug substances and products. From a CMC perspective, a better use of resources might be toward understanding PQ as it relates to drug stability and potency, setting appropriate process parameters, and expanding drug shelf-life through appropriate improvements in formulation and analytical development (21).

Current and Future Objectives

CMC teams constantly seek novel approaches to expedite the development of a biotherapeutic as soon as a development candidate is nominated and when an IND-enabling study begins. Major advances have been achieved by exploiting early stage pools to develop processes and assays. However, drug developers still have an apparent need to determine stability of pools and derived clones as soon as cell lines are established. In the next five years, the bioprocessing industry is likely to see investment of resources into determining phenotypic and genotypic features that inform on key cell-line attributes of productivity, recovery time, scalability, and stability.

References

1 Guidance for Industry: Cell Characterization and Qualification of Cell Substrates and Other Biological Materials Used in the Production of Viral Vaccines for Infectious Disease Indications. US Food and Drug Administration: Rockville, MD, 2010.

2 Guidance for Industry: Q5A Viral Safety Evaluation Derived from Cell Lines of Human or Animal Origin. US Food and Drug Administration: Rockville, MD, 1998.

3 Guideline for Industry: Q5B Quality of Biotechnological Products — Analysis of the Expression Construct in Cells Used for Production of r-DNA Derived. US Food and Drug Administration: Rockville, MD, 1996.

4 Morar-Mitrica S, et al. An Intercompany Perspective on Biopharmaceutical Drug Product Robustness Studies. J. Pharm. Sci. 107(2) 2018: 529–542; https://doi.org/10.1016/j.xphs.2017.10.017.

5 Guidance for Industry: Process Validation “General Principles and Practices.” US Food and Drug Administration: Rockville, MD, 2011.

6 Lewis NE, et al. Genomic Landscapes of Chinese Hamster Ovary Cell Lines as Revealed by the Cricetulus griseus Draft Genome. Nat. Biotechnol. 31(8) 2013: 759–765; https://doi.org/10.1038/nbt.2624.

7 ICH Q5D Quality of Biotechnological Products: Derivation and Characterisation of Cell Substrates Used for Production of Biotechnological/Biological Products. European Medicines Agency: London, UK, 2007.

8 Balasubramanian S, et al. Generation of High-Expressing Chinese Hamster Ovary Cell Pools Using the Leap-In Transposon System. Biotechnol. J. 13(10) 2018: e1700748; https://doi.org/0.1002/biot.201700748.

9 Misaghi S, et al. Slashing the Timelines: Opting to Generate High-Titer Clonal Lines Faster Via Viability-Based Single-Cell Sorting. Biotechnol. Prog. 32(1) 2016: 198–207; https://doi.org/10.1002/btpr.2204.

10 Dahodwala H, Lee KH. The Fickle CHO: A Review of the Causes, Implications, and Potential Alleviation of the CHO Cell Line Instability Problem. Current Opin. Biotechnol. 60, 2019: 128–137; https://doi.org/10.1016/j.copbio.2019.01.011.

11 Frye C, et al. Industry View on the Relative Importance of “Clonality” of Biopharmaceutical-Producing Cell Lines. Biologicals 44(2) 2016: 117–122; https://doi.org/10.1016/j.biologicals.2016.01.001.

12 Supplement to Points to Consider in the Production and Testing of New Drugs and Biologics Produced By Recombinant DNA Technology: Nucleic Acid Characterization and Genetic Stability. US Food and Drug Adinistration, CBER: Rockville, MD, 1992.

13 Fan L, et al. Comparative Study of Therapeutic Antibody Candidates Derived from Minipool and Clonal Cell Lines. Biotechnol. Prog. 33(6) 2017: 1456–1462; https://doi.org/10.1002/btpr.2477.

14 Das TK, et al. Stress Factors in MAb Drug Substance Production Processes: Critical Assessment of Impact on Product Quality and Control Strategy. J. Pharm. Sci. 109(1) 2020: 116–133; https://doi.org/10.1016/j.xphs.2019.09.023.

15 Xu Y, et al. Structure, Heterogeneity and Developability Assessment of Therapeutic Antibodies. MAbs 11(2) 2019: 239–264; https://doi.org/10.1080/19420862.2018.1553476.

16 Guideline for Industry ICH Q5C: Quality of Biotechnological Products: Stability Testing of Biotechnological/Biological Products. Fed. Regist. 61, 1996: 36466.

17 Munro TP, et al. Accelerating Patient Access to Novel Biologics Using Stable Pool-Derived Product for Nonclinical Studies and Single Clone-Derived Product for Clinical Studies. Biotechnol. Prog. 33(6) 2017: 1476–1482; https://doi.org/10.1002/btpr.2572.

18 Jain NK, et al. A High-Density CHO-S Transient Transfection System: Comparison of ExpiCHO and Expi293. Protein Expr. Purif. 134, 2017: 38–46; https://doi.org/10.1016/j.pep.2017.03.018.

19 Sandner V, et al. Scale-Down Model Development in ambr Systems: An Industrial Perspective. Biotechnol. J. 14(4) 2019: e1700766; https://doi.org/10.1002/biot.201700766.

20 Mora A. et al. Early Integration of Design of Experiment (DoE) and Multivariate Statistics Identifies Feeding Regimens Suitable for CHO Cell Line Development and Screening. Cytotechnol. 71(6) 2019: 1137–1153; https://doi.org/10.1007/s10616-019-00350-1.

21 Kelley B, Kiss R, Laird M. A Different Perspective: How Much Innovation is Really Needed for Monoclonal Antibody Production Using Mammalian Cell Technology? Advances in Biochemical Engineering/Biotechnology. Scheper T, Ed. Springer Science and Business Media: Berlin, Germany, 2018: 443–462.

Corresponding author Alessandro Mora was formerly a principal scientist at Jounce Therapeutics; [email protected]. Yassine Ezzyat is an associate scientist at Jounce Therapeutics.

You May Also Like