Viral Nanofilter Integrity: Using Variable-Pathlength UV-Vis Spectroscopy for the Gold Nanoparticle TestViral Nanofilter Integrity: Using Variable-Pathlength UV-Vis Spectroscopy for the Gold Nanoparticle Test

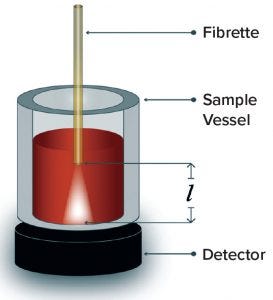

Figure 1: Mechanism of variable-pathlength UV-vis technology; l = the distance between the tip of the light-delivering fibrette and the inside bottom of the sample vessel.

Viral filtration (VF) using nanofilters removes endogenous and/or adventitious viruses from biologic drug-substance manufacturing processes (1). The gold particle test (GPT) is performed as part of postuse integrity testing — to complement postuse leakage testing — for cellulose filters such as Planova 20N filters from Asahi Kasei Corporation.

First, a proprietary gold-colloid solution matched to the filter type (e.g., 20N) is filtered through the test article. That filter’s pore-size distribution can be assessed using spectrophotometric absorbance readings of the integrity-test solution — e.g., 1:10 dilution of Asahi Gold Particle solution AGP-HA20 to test Planova 20N — and the correct filtrate sample (minimum volume collected for measuring absorbance) to calculate the gold-particle removal rate as a logarithmic reduction value (LRV).

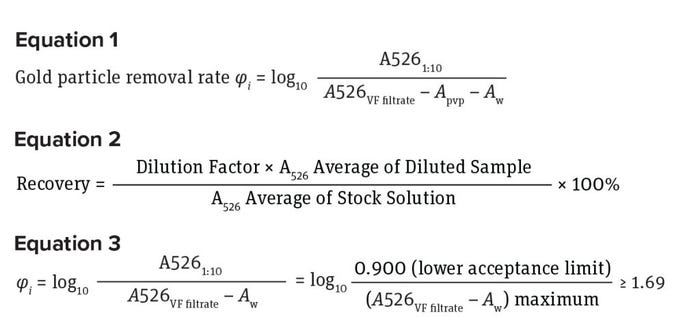

That rate is determined as in Equation 1, where

A5261:10 = absorbance of the 1:10 dilution of AGP-HA20 solution at 526 nm

A526VF filtrate = absorbance of the filtrate sample at 526 nm

APVP = absorbance of 0.25% PVP (polyvinyl pyrrolidone) solution in AGP-HA20 solution at 526 nm

Aw = absorbance of water for injection (WFI) at 526 nm (baseline correction).

According to vendor recommendations, the required postuse integrity passing criterion for Planova 20N GPT is a gold-particle removal rate of φi ≥ 1.40. For this study, the passing criterion was set as φi ≥ 1.69. Because the value for APVP typically is close to 0 (0.000 or 0.001) (2), we did not include it in our analyses below.

Slope Technique Using Variable-Pathlength UV-Vis Spectroscopy: Nearly all traditional ultraviolet-visual (UV-vis) spectroscopic methodologies currently rely on standard fixed-pathlength UV-vis absorbance readings. Several issues can arise from using that method based on the need for careful sample handling and preparation. One critical task is creating the dilutions needed for bringing samples into the linear range of an instrument’s calibration. Errors introduced when performing those dilutions can affect optical density (OD) readings and calculated sample concentrations significantly. In some cases, assay error can be greater than the acceptable range of variance from a target value, which would call into question the validity of the method itself.

Unlike traditional UV-vis methods that rely on a single absolute absorbance value, slope-spectroscopy methods use section data at the wavelength of interest (absorbance/pathlength) to determine a slope value for quantitation of sample concentration using the slope-spectroscopy equation (m = εc), which is derived from the Beer–Lambert Law. The Beer–Lambert Law is expressed as

A = α × l × c

where A is measured absorbance, α is wavelength-dependent molar-absorption coefficient, l is pathlength, and c is sample concentration.

Equations

The SoloVPE instrument from C Technologies Inc. (Repligen) enables users to measure the absorbance of a sample quickly at different pathlengths. During SoloVPE operation, the pathlength l is defined by the distance between the tip of a light-delivering fibrette and the inside bottom of the sample vessel (Figure 1).

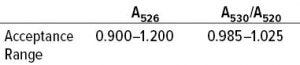

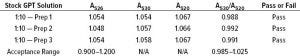

Table 1: Qualification criteria for stock gold-particle test GPT solution (1:10 AGP-HA20) (3).

The pathlength is controlled dynamically through precise movement of the fibrette up and down in the sample, which is accomplished by integrated hardware and software. Variable-pathlength technology allows samples with a wide range of concentrations to be measured directly, usually without further handling requirements (e.g., sample dilution/concentration) or baseline correction. The SoloVPE instrument precisely controls pathlength changes with a resolution of 5 µm. That can be verified readily by examining the strength of correlation on regressed-wavelength cross-section plots. R2 (the linear regression coefficient) values close to one confirm that the absorbance values are changing proportionally with pathlength in accordance with the Beer–Lambert Law.

Materials and Methods

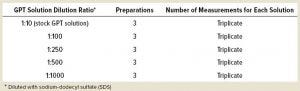

Table 2: GPT solutions tested with the SoloVPE instrument

Materials: Our data were generated by a SoloVPE instrument installed on an Agilent Cary 60 UV-vis spectrophotometer. C Technologies supplies three sizes of fused-silica sample vessels (cuvettes) — large (2 mL), small (200 µL), and micro (100 µL) — to accommodate different sample concentrations. The required sample volume is inversely related to the expected sample concentration. According to the Beer–Lambert Law

(A = α × l × c), less-concentrated samples require longer pathlengths to obtain a given absorbance (3) and, hence, larger sample volumes. In this GPT filter-integrity application, and considering the trace concentration of potential gold nanoparticles in the viral filtrate, we used large fused-silica vessels (2 mL) for all measurements. GPT solutions came from Asahi Kasei Bioprocess in the form of an AGP-HA20 kit.

Methods: We prepared gold-nanoparticle solutions and measured their absorbance as follows (3):

Preparation of stock GPT solution (1:10 dilution of AGP-HA20) using freshly prepared 0.27% (w/v) sodium-dodecyl sulfate (SDS) reagent

Measurement of stock GPT solutions prepared by filling a large cuvette to 2 mL (with a new fibrette and clean cuvette used for each sample measurement)

Measurement of stock GPT solutions at 526, 520, and 530 nm using the SoloVPE instrument’s “quick-slope” mode

Stock GPT solution checked to ensure that it met qualification criteria listed in Table 1 before executing the remaining experiments.

Table 3: Qualification results of stock GPT solution (1:10); each absorbance value is the average of triplicate readings.

Slope (Abs/mm) reported from the SoloVPE scan was multiplied by 10 so that it would be reported in Abs/cm and labeled as absorbance slope A at a certain wavelength (e.g., A526).

WFI absorbance subtraction was performed for all reported A520, A526, and A530 values of the stock GPT solution.

Results

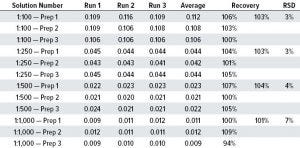

Table 4: SoloVPE A526 results for GPT dilution series; RSD = relative standard deviation

Qualification of Stock GPT Solution: Table 3 lists SoloVPE absorbance results for three stock GPT solutions. All three preparations passed the vendor’s recommended acceptance criteria.

A526 of GPT Diluted Solutions: We calculated recovery by Equation 2 to estimate the amount of gold nanoparticles in the solutions (1:100, 1:250, 1:500, 1:1,000 preparations) recovered from the initial stock solution (1:10 preparation). As Table 4 shows, A526 recovery for each preparation of diluted GPT solution fell within ±10% of the corresponding stock GPT solution (average of the three preparations at 1:10 dilution, Table 3), assuming that the recovery for the stock solution was 100%. Those results indicate that even at a 1:1,000 dilution, the A526 value still reflected an absorbance signal rather than background noise. Moreover, the relative standard deviation (RSD) of the samples — defined as the ratio of the samples’ standard deviation to the mean — was <10% among three preparations for each dilution ratio.

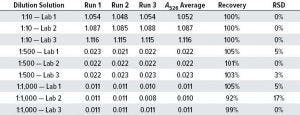

Table 5: Comparison of A526 of GPT solutions using different SoloVPE equipment;

RSD = relative standard deviation

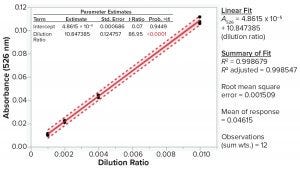

Range of Linearity and Limit of Detection: Using the Table 4 results, we established a linear-fit model between A526 and the GPT dilution ratio using JMP 13 software (Figure 2). Four GPT dilution ratios (1:1,000, 1:500, 1:250, and 1:100) were plotted against their corresponding A526 values. For each dilution ratio, average A526 results are shown for each preparation (triplicate readings).

We established a linear-fit model between A526 and the dilution ratio with a linear-regression coefficient R2 adjusted value of 0.999 for dilutions ranging from 1:100 to 1:1,000 (0.01-0.1 A526). According to the GPT integrity test document, the pass–fail A526 level for a filtered GPT solution is 0.018 (2). This absorbance fell within the linear range of the SoloVPE instrument.

Figure 2: Linear fit model of A526 and GPT dilution ratio

To confirm that measurements at this level (0.01 A526) would be quantitatively meaningful, we assessed the accuracy and precision of absorbance measurements at the low end of the linearity range. Determining the limit of detection (LoD) is important for trending analysis of filter-integrity test results. We assessed this accuracy based on calculated recoveries at each dilution level (based on the linear regression equation) as well as on the precision of independent replicate measurements. The accuracy of individual measurements is within ±10%, and the precision (based on RSD of three replicate measurements) was <10% — which collectively indicates that measurements at this level can be determined reliably.

Demonstrating Interassay Precision from Different SoloVPE Instruments: SoloVPE measurements have no potential for error of dilution or concentration. Such errors are inherent to traditional A280 measurements, requiring test solutions to be adjusted to concentrations that fall within the linear range of absorbance. At high absorbance values, SoloVPE measurements can be performed without background correction or sample dilution. The linear range measured for dilute solutions spans the lower range of the SoloVPE instrument linearity, which requires measurement using the maximum pathlength and background correction (using WFI in this study). In addition to the potential for a lack of linearity in this range, differences in the flowpath length and diameter between instruments could create differences in response and thus cause a bias in accuracy between separate instruments.

To assess the variability of response and reproducibility among SoloVPE instruments, we used three separate laboratories to perform similar A526 measurements using the same GPT solutions measured above. Different analysts used the instruments without specific preparation or calibration, with the same preparations of GPT solution. Table 5 lists their results together with A526 readings acquired from our own laboratory SoloVPE instrument (Lab 1). All A526 slope readings display values with the WFI background subtracted.

For all three SoloVPE instruments tested at different laboratories, the A526 values were closely comparable for GPT solutions at 1:10, 1:500, and 1:1,000 dilution ratios, indicating strong assay repetitiveness and robustness. No significant absorbance bias was observed for different SoloVPE instruments measuring the above series of diluted GPT solutions. One comparison instrument (Lab 2) did show reduced precision (17% RSD) compared to the others; however, that probably is the result of noise at the limit of quantitation (LoQ).

GPT Integrity Testing: According to the viral-filter vendor’s recommendation and our own company’s internal process control strategy, the criterion for a filter to pass the GPT integrity test after viral filtration is to have a gold-particle removal rate of φi > 1.69. The lowest A526 slope of stock GPT solution (1:10 dilution) to pass the recommended vendor’s acceptance limit is 0.900 (Table 1). So the worst-case maximum A526 of VF filtrate to pass this criterion is calculated to be 0.018 according to the derivation in Equation 3.

Based on the results presented above, the LoQ of SoloVPE instruments to measure absorbance of GPT solutions is determined to be ≤ 0.010 A526, which is lower than the worst-case pass–fail A526 criterion for the VF filtrate (0.018 A526). Therefore, our results demonstrate that the instrument can determine GPT solution absorbance accurately at the level required to support GPT integrity testing of Planova filters.

Discussion

GPT is used to determine the integrity of Planova cellulose filters after viral filtration in biopharmaceutical downstream processing. The postuse gold-particle removal rate (φi) is set to be >1.69 at our company for a filter to pass the postuse filter-integrity test.

We evaluated the use of SoloVPE instruments for gold-particle testing to establish which GPT dilutions fall within the linear range of the instrument and to demonstrate the robustness of the method across multiple instruments. We established that a series of diluted GPT solutions from 1:100 down to 1:1,000 fall within the instrument’s linear range, establishing a linearity-fit model between A526 and dilution ratio of GPT solutions with a linear regression coefficient R2 adjusted value of 0.999. The instrument can measure absorbance at the 1:1,000 dilution level with sufficient accuracy (within ±10% of its calculated value) and precision (<10% RSD for triplicate measurements). Determination by SoloVPE was robust as well, with no significant bias among instruments tested in three different laboratories.

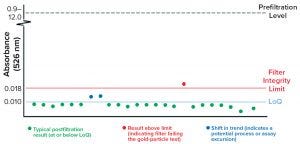

Figure 3: Demonstration of GPT analytical significance in CGMP manufacturing

The typical absorbance range observed for GPT solutions after filtration through postuse Planova filters in our GMP manufacturing facility is <0.010 A526. Even though all values fall below the pass–fail absorbance criterion (0.018 A526), the trending of GPT results can be a useful measure of process consistency. Shifts or trends in the absorbance of filtered solutions could correlate to process deviations. Moreover, an upward trend in absorbance can indicate a change in filter quality, and a downward trend could indicate a loss of assay sensitivity. Figure 3 shows a theoretical trend of GPT test results, including the pass–fail limit (0.018 A526) and LoQ (0.010 A526) that establish the levels outside which shifts or trends in absorbance would be considered significant.

Although the dilution factor required for determining filter integrity is higher than 1:1,000, absorbances observed for GPT solutions during the filter-integrity test typically fell within that low absorbance range. Determination of the linear range and LoQ was useful for trending analysis of this process operation’s consistency. The quantitation limit identifies the level above which differences in absorbance readings represent real differences in filter-test results. Our results demonstrate that SoloVPE instruments can determine GPT solution absorbance accurately at the levels required to support decision making for postuse integrity testing of Planova 20N filters.

The liner range and limit of quantitation (0.01 AU) for this method with Planova 20N filters could be extended to use with 15N and 35N Planova filters, which require a larger postuse gold particle test removal rate.

Acknowledgments

We thank Joe Ferraiolo (applications manager at C Technologies, a Repligen company) for helpful discussions on variable-pathlength UV-vis spectroscopy.

References

1 ICH Q5A(R1). Viral Safety Evaluation of Biotechnology Products Derived from Cell Lines of Human or Animal Origin. US Fed.Reg. 63(185) 1998: 51074; https://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q5A_R1/Step4/Q5A_R1__Guideline.pdf.

2 TAS33031, version 3.1: Standard Operation Procedure for Integrity Test: GPT (AGP-HA). Asahi Kasei Medical Co., Ltd.: Tokyo, Japan, 25 February 2019.

3 Ferraiolo J, Shanbaky R. Characterization of Gold Nanoparticle Detection Using Slope Spectroscopy (SoloVPE Variable Pathlength UV). C Technologies, Inc.: Bridgewater, NJ, 2017; https://ctechnologiesinc.com/sites/default/files/2017-10/SoloVPE-Gold-Particle-Testing.pdf.

Further Reading

Huffman S, Soni K, Ferraiolo J. UV-Vis Based Determination of Protein Concentration: Validating and Implementing Slope Measurements Using Variable Pathlength Technology. BioProcess Int. 12(8) 2014: 66–73.

Lehr B, et al. Evaluation of a Variable-Pathlength Spectrophotometer: A Comparable Instrument for Determining Protein Concentration. BioProcess Int. 13(6) 2015: 46–51.

Corresponding author Zhen Tong ([email protected]) is a scientist, and Juma Bridgewater ([email protected]) and Nuria de Mas ([email protected]) are associate directors, all in biologics drug-substance manufacturing sciences and technology at Bristol-Myers Squibb, 38 Jackson Road, Devens, MA 01434.

You May Also Like