Hydrating Media Powder at the 200-L Scale Using a Magnetic MixerHydrating Media Powder at the 200-L Scale Using a Magnetic Mixer

July 1, 2009

Figure 1:

ATMI® LifeSciences offers five different disposable mixing technologies that provide varied cost, operational, and performance advantages over conventional stainless steel mixing vessels and competing disposable mixers. Criteria for selecting the best ATMI mixing technology include scale, particle, and sheer sensitivity, mixing power, physical fit, and economic considerations. This application note illustrates how the LevTech® Magnetic Mixing system performs in a demanding media mixing application.

Introduction

The LevTech Magnetic Mixer is a compact and noninvasive single-use mixing system. The mixing bag incorporates a bottom-mounted, magnetically driven impeller that provides high-torque mixing for powder–liquid and liquid–liquid applications. The impeller rides on a low-friction, inert bearing assembly designed to ensure low particle shedding while allowing mixing of high powder loads in large liquid volumes. All product-contacting surfaces are USP Class VI, ADCF, and 100% disposable.

Powder–liquid mixing is a common requirement in biopharmaceutical processing. To maximize mixing efficiency for powder–liquid applications, the Magnetic Mixer is available with a large (6.35”) centrally located impeller.

In this experiment, a Magnetic Mixer was used to prepare cell culture media. The procedure entailed the dissolution of serum-free CHO dry powder medium, and then adjustment of the solution pH using readings from sensors installed in the mixing bag.

Experimental

A 200L Magnetic Mixer mixing bag was fitted with a pair of calibrated, autoclavable glass pH electrodes through threaded probe ports. The mixing bag was then filled with ~180 L of water at room temperature, and the impeller mixing speed was set to 300 rpm. The recommended amount of dry media powder (4,242 g) was added through the top of the mixing bag via a Newsafe 30L contained Powder Transfer Bag (cPTB). No media powder or dust was observed escaping during this addition, and powder delivery to the mix vessel was >99.9%.

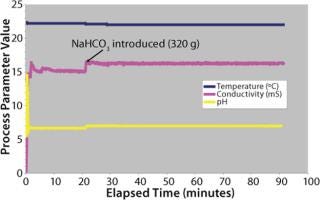

Figure 1: ()

Following the media manufacturer’s guidelines, after 20 minutes of mixing, 320 g of sodium bicarbonate powder was added, and the solution was adjusted to pH 7.00 with sodium hydroxide or hydrochloric acid. The solution was then mixed for 60 minutes as recommended. Homogeneity was monitored with real-time conductivity and real-time pH.

Results

The accompanying chart shows solution homogeneity in the bag during mixing. After the media powder addition, mixing was deemed (from the conductivity data and visual observation) to be complete within about 12 minutes. After the bicarbonate addition and pH adjustment, mixing was deemed complete within a further eight minutes. At no time during the mixing process did the impeller stall or hesitate.

Conclusions

The LevTech Magnetic Mixing system, coupled with a Newsafe cPTB, is well suited to preparation of cell culture media solution. Media preparation times in the 20–30 minute range appear feasible at the tested volume and medium concentration.

You May Also Like