In-Line Turbidity Sensors for Monitoring Process Streams in Continuous Countercurrent Tangential Chromatography (CCTC)In-Line Turbidity Sensors for Monitoring Process Streams in Continuous Countercurrent Tangential Chromatography (CCTC)

Sponsored by PendoTECH

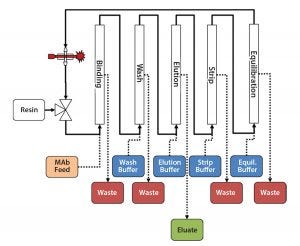

Figure 1: PendoTECH turbidity flowcell placed at the resin outlet of the CCTC; resin passing through the flowcell indicates a signal breakthrough, and the system is set to recirculation once the resin in the system has reached steady state. The steady-state “peak-free”product stream can be measured in-line with PendoTECH UV flowcells.

A strong connection between turbidity and total suspended solids (TSS) has been linked in the past to measuring well defined particles in processes. Optical density probes have seen wide adoption in the biotechnology industry for monitoring cell growth within a bioreactor, whereas in-line turbidity sensors have been used to monitor filter performance. Turbidity measurements offer a rapid quantification of suspended

solids but have not been used in the biotechnology industry for chromatographic resins. In this study, turbidity measured with equipment developed by PendoTECH was used with novel continuous chromatography technology developed by Chromatan for

accurate measurements of chromatography resin slurry concentrations.

CCTC

CCTC

Continuous countercurrent tangential chromatography (CCTC), developed by Chromatan Corporation, has overcome many limitations of batch columns without

the drawbacks of multicolumn systems (1). The CCTC platform is a true moving-bed technology that runs at steady state and eliminates the use of columns. The system’s novel design enables short residence times, consistent product concentration and quality, and easier implementation of advanced process analytical technology (PAT) and process control. In addition, CCTC is uniquely suited for processing sensitive molecules because of its ability to control buffer and micromixing conditions independently for all chromatographic steps. That eliminates product-related concentration and buffer gradients that always accompany column-based separations.

The patented CCTC system includes all of the traditional chromatographic process steps: binding, washing, elution, stripping, and equilibration. Those are comparable with traditional batch chromatography, but they are conducted simultaneously on a moving slurry rather than with the step-wise batch approach of a packed column (Figure 1). Each step comprises a cascade of stages that consist of a single static mixer connected

The patented CCTC system includes all of the traditional chromatographic process steps: binding, washing, elution, stripping, and equilibration. Those are comparable with traditional batch chromatography, but they are conducted simultaneously on a moving slurry rather than with the step-wise batch approach of a packed column (Figure 1). Each step comprises a cascade of stages that consist of a single static mixer connected

in series to a hollow-fiber membrane. Countercurrent configuration of these stages enables enhanced impurity removal and higher yield for each chromatographic step. The static mixers provide sufficient residence times for adsorption/desorption to occur. The microporous hollow-fiber membranes retain the large resin particles while

allowing all dissolved compounds (proteins and salts) to diffuse across the membrane into the permeate.

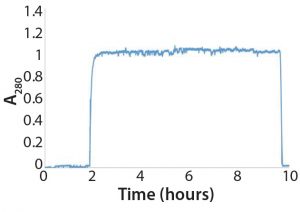

The CCTC system has been shown to operate continuously 5-15× higher productivity than with batch columns, with the product eluting at steady state. The steady-state “peak-free” product stream can be measured in-line for product quality attributes. The steady-state nature of the process also enables seamless integration with other

continuous/in-line unit operations. More details are provided in Dutta et al. (2).

Figure 2: End-to-end integrated bioproduction using CCTC in development at Chromatan

As a consequence of these benefits, The National Institutes of Health (NIH) has funded a US$1.75 million Fast-Track Phase 2 SBIR to support the integration of CCTC and a perfusion bioreactor into a single steady-state bioproduction platform. The FDA also has financed a $2.5 million contract to develop and

commercialize a fully integrated continuous downstream process that includes capture, intermediate, and polishing CCTC steps for antibody purification (Figure 2).

As a major strategic deliverable, both integration project s require significant

developments of in-line process analytical technologies (PAT) and continuous process monitoring. Single-use sensors for process parameters such as pH, conductivity, flow rate, and pressure have been developed and tested by the industry. However, because

of the true moving-bed nature of CCTC, it also has become necessary to develop a

robust in-line measurement for accurate determination of chromatography resin

concentration in the CCTC slurry

Figure 3: Turbidity flowcell options from PendoTECH — fixed pathlength single-use flow cells (left) and adjustable pathlength flowcell (right).

PendoTECH

PendoTECH offers in-line single-use UV absorbance and turbidity measuring and monitoring systems that collect data from bioprocess fluid streams. Three single-use

polysulfone optical flowcells with pathlengths of 2 mm, 5 mm, and 1 cm with hose-barb process connections can be installed in-line to any process stream. Reusable couplers for focusing light are screwed into the flowcell. Fiber-optic cables connect the couplers to the light source and to the detector in the compact photometer. The output from the photometer is a 4-20 mA signal scaled 0-2 AU. The systems use an LED to generate a single wavelength of light, customizable by PendoTECH from 240 nm to 1,000 nm. Additionally, PendoTECH offers a stainless steel flowcell with adjustable pathlengths of 0.05-2.0 mm, allowing end users to set the pathlength for a linear response to the process stream. Figure 3 shows the flowcell offerings.

Past work has demonstrated that using the principles of the Beer-Lambert law, a flowcell pathlength can be selected to measure a process stream accurately in its linear range (3). A 2-mm pathlength flowcell has been used with a 280-nm light source to measure the elution stream of a protein in a capture process in the CCTC. This in-line sensor provides accurate concentration and yield measurements at one-second intervals, enabling PAT.

Materials and Methods

Resin Preparation: Two resin types were tested: an agarose backbone 22-µm resin from Purolite; and POROS 50HQ, a polystyrene divinylbenzene (PSDVB)

backbone 50-µm particle-size resin from Thermo Fisher. PSDVB is used as a

standard for calibrating turbidity meters. The agarose resin is significantly less

turbid. Using these materials enabled investigations of the in-line turbidity at a

wide range of slurry ratios and absorbances.

Stocks of both resins were exchanged into 1 × PBS and prepared into 20%, 10%, 5%, and 2.5% v/v slurry ratios. The slurry ratios of all the stocks were measured in duplicate by gravity settling for 24 hours in 12.5-mL Koehler K61141 centrifuge tubes.

Offline Turbidity Meter: A Hach 2100Q turbidity meter, a nephelometer with a 90° detector angle from incident light and 1-inch pathlength, was calibrated with Stabical Formazin primary standards from 10 to 800 NTU and used to measure the primary stocks of agarose and PSDVB resin slurries. The 2100Q has a maximum reporting turbidity of 1,000 NTU. Traditional nephelometers can provide an accurate measurement of turbidity up to 2,000 NTU depending on the excitation light source and detector configuration.

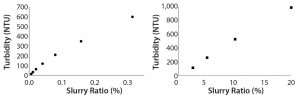

The agarose measured with the 2100Q demonstrated a strong linear relationship for the measured slurry ratios 2.5%-20% v/v slurry ratio and 120-1000 NTU, as shown in Figure 4, with an R2 of 0.99.

Figure 4: Poros 50HQ (circles) and Purolite (squares) resins were measured with a benchtop Hach 2100Q turbidity meter. Purolite could be measured directly for slurry ratios 2.5−20% v/v with a strong correlation between the NTU and the slurry ratio. The Poros resin was too turbid and needed to be diluted to a slurry ratio <0.35% v/v.

Although Formazin is the only recognized primary standard for calibrating turbidity meters because of its relative stability, size distribution, and consistent 90° light scatter, PSDVB also has been used as a primary standard for calibrating turbidity meters. However, the PSDVB slurries saturated the detector. The 2.5% slurry stock of PSDVB was diluted into range, and a dilution curve from 0.004% to 0.31% v/v slurry was generated from 20 to 600 NTU (Figure 4). ISO 7027-compliant nephelometers are

limited in this regard and provide only a linear measurement that can be used for

quantification of suspended solids such as resin only from 0 to 40 NTU, necessitating a large dilution factor. In a practical sense, however, the large dilution factor could introduce a significant source of error that might interfere with efficient loading of resin

into the CCTC system.

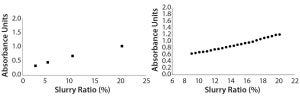

Figure 5: Purolite (squares) and Poros 50HQ (circles) resins were monitored with a PendoTECH flowcell at 880 nm with pathlengths set to 2 mm and 0.5 mm, respectively. The Purolite resin had a linear range for slurry ratios 2.5−20% and an R2 of 0.99. The Poros resin had a linear range for slurry ratios 6.5−20% and an R2 of 0.99.

PendoTECH Turbidity Meter: A test solution was agitated with an overhead mixer set to 400 rpm, and a peristaltic pump delivered the fluid through the flowcell in an upflow configuration and back to the beaker. The agarose resin had a linear relationship for transmittance in a 2-mm pathlength for the slurry ratio range of 2.5-20% with an R2 of 0.99 (Figure 5). The PSDVB resin was beyond the linear range for a 2-mm pathlength and slurry ratios >10% v/v. Further testing was performed with shorter pathlengths.

Both resins demonstrated a stable equivalent reading for flowrates 5-40 mL/min at the same slurry ratios.

A 20% stock of PSDVB was prepared and serially diluted with an identical setup to the agarose resin, but with a shorter pathlength. The PSDVB resin had a linear relationship for transmittance in a 0.51-mm pathlength for the slurry ratio range of 5-20% with an R2 of 0.99 (Figure 5). Additionally, the PSDVB testing demonstrated that tuning into a linear range is readily accomplished with the PendoTECH stainless steel flowcell by adjusting the pathlength. The experiment also demonstrated strong sensitivity to slurry ratio and can be used to quantify the exact concentration of resin being circulated within the CCTC system.

Integration with CCTC

Flowcells and photometers offered by PendoTECH enable in-line monitoring of process streams for CCTC in both single-use and reusable formats. This study demonstrates that in addition to monitoring product titers, optical sensors also can be used for measuring and controlling CCTC resin concentrations.

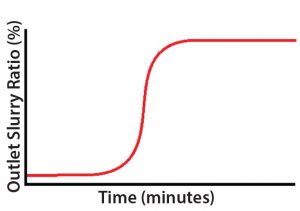

The flowpath in Figure 1 shows an integrated PendoTECH optical sensor at the resin-loading manifold. The location of the sensor helps determine resin cycle time in the CCTC, which is used to calculate resin volume and CCTC productivity. The sensor also measures outlet slurry ratio, providing in-line measurement of timing to reach steady-state. Once the outlet resin concentration reaches the inlet, the CCTC system automatically switches the flow path into a closed loop resin circulation mode

(by-passing the resin tank). With the known cycle time, resin also can be unloaded once the full lifetime has been reached and replaced with fresh resin if necessary.

Additionally, monitoring the exact concentration entering the binding step allows for precise resin loading. This has a strong effect on output yield and product quality especially for ion-exchange operations. Unlike batch columns, in which concentration gradients and product peaks are a direct consequence of the sequential batch operation, the CCTC can target exact loading and elution conditions throughout the

process without compromising yield or product quality.

Overall, the PendoTECH single-use flowcells and customizable photometers open a wide range of possibilities for in-line process control and PAT. Turbidity and UV sensors enable the CCTC platform to provide accurate measurements of titer and yield in the product streams as well as accurate resin concentration measurements for system startup and efficient resin cycling.

Chromatan and PendoTECH believe that joining together to develop such technologies is essential for development and eventual adoption of continuous single-use manufacturing at the current good manufacturing practice (CGMP) scale. We look forward to initiating and continuing such collaborations with one another, as well as with other customers and suppliers.

References

1 Dutta AK, et al. Continuous Countercurrent Tangential Chromatography for Mixed Mode Post-Capture Operations in Monoclonal Antibody Purification. J. Chromatogr. A 1511, 2017: 37–44; doi:10.1016/j.chroma.2017.06.018.

2 Dutta AK, et al. Performance Optimization of Continuous Countercurrent Tangential Chromatography for Antibody Capture. Biotechnol. Prog. 32(2) 2016: 430–439;

doi:10.1002/btpr.2250.

3 Renaut P, Annarelli D. Evaluation of a New Single-Use UV Sensor for Protein A

Capture. BioProcess Int. 11(2) 2013: 48–51.

Corresponding author Dmitriy Fedorenko is associate director at Chromatan Corporation; [email protected]. Jasmine Tan is associate scientist II and Oleg Shinkazh is CEO at Chromatan Corporation. Dennis Annarelli, PhD, is technical manager at PendoTECH; [email protected].

You May Also Like