The International Society for Cellular Therapy (ISCT) will host its

21st Annual Meeting

at Caesars Palace Hotel and Convention Center, Las Vegas, NV, 27–30 May 2015. More than 1,200 industry and regulatory professionals, clinicians, scientists, and laboratory professionals are expected to attend. The program covers six plenary sessions, six workshops, three technical sessions, and more than 20 total track sessions covering such topics as advances in cell therapy research, commercialization strategies, quality and operations, and regulatory issues.

BPI spoke with plenary speakers and chairs of the “Strategies for Commercialization” track about how ISCT and cell therapy professionals are advancing the field. Here, they introduce the “hot topics” within commercialization and issues driving the cell therapy industry into its “coming of age” from R&D and early phase development, through clinical development, and ultimately to market launch.

Presidential Plenary

Massimo Dominici is President of ISCT and assis...

Today’s competitive financial and market conditions demand that biopharmaceutical companies constantly innovate and create to deliver on promised milestones. In addition to strengthening and improving robust monoclonal antibody (MAb) and other protein pipelines, a number of biopharmaceutical companies are significantly investing, developing, and broadening their research and development efforts and product pipelines with what many are calling the “next generation” of biopharmaceuticals. Those include antibody–drug conjugates (ADCs); biosimilars and biobetters; cell, gene, and tissue therapies; and vaccines and immunotherapies.

In efforts to fulfill both the medical promise of biotherapeutics and the business expectations of investors, as well as the safety and quality requirements of regulators, biopharmaceutical companies must continually find new solutions. These include both novel technological advances and improvements to existing expression systems, delivery platforms, and development and manufacturi...

Barth syndrome is a serious X-linked genetic disorder that primarily affects boys. It is caused by a mutation in the tafazzin gene (

Taz

) that creates an inborn error of lipid metabolism. The condition is named after Dutch pediatric neurologist Peter Barth, who published his discovery of it in 1983.

The syndrome often manifests at birth in a number of ways. Patients are born hypotonic, show signs of cardiomyopathy within the first few months of life, and despite adequate nutrition experience a deceleration in growth through their first year. On into childhood, their height and weight lag significantly behind those of other children. Physical activity is limited by diminished muscular development and muscular hypotonia. Some issues resolve themselves after puberty, during which growth accelerates, with patients reaching a normal adult height.

A boy’s myocardium is dilated in Barth syndrome cardiomyopathy, reducing the systolic pump of his heart ventricles. So most patients develop left-side myocardial hyp...

WWW.JUPITERIMAGES.COM

Viral safety is required for biologics manufactured to treat human diseases. Although significant improvements in ensuring viral safety have been made over the past few decades, “zero risk” of viral contamination is a myth. Viral contamination risk can be carefully managed by screening raw materials, testing process intermediates, and evaluating how effectively manufacturing processes remove and inactivate viruses.

Viral clearance studies verify virus removal or inactivation by a manufacturing process. Although regulatory agencies have expectations for the designs of those studies, no standard expectations for clearance levels apply to every product. Just as each biologic and the raw materials and manufacturing process used to generate it are unique, so too are the risks of viral contamination and viral clearance expectations.

A product’s expected level of clearance depends on the potential viral contaminant load in its source materials. That level incorporates additional clearance f...

Stability testing is a vital part of product development and is conducted throughout a product’s life cycle (Figure 1). Stability is part of a biotherapeutic’s quality target product profile, and results help analysts understand how critical quality attributes (CQAs) of both drug substances and products are influenced under specific conditions of temperature, relative humidity (RH), light, storage, pH, and other factors. Manufacturers conduct stability tests to determine degradation pathways and establish shelf lives and storage conditions of their products, for example. Tests and bioassays related to purity, identity, potency, quality, and safety are conducted depending on the product type and intended use.

Figure 1: The purpose of stability testing throughout a biologics’s life cycle (22)

This overview presents some current issues with testing the stability of current and next- generation biologics. Although it is impossible to thoroughly cover all aspects of stability testing in this space, many availa...

https://bioprocessintl.com/wp-content/uploads/2015/05/052015_qui.mp3

During the manufacturing of monoclonal antibody (MAb) products, many process reagents are used for cell culture and MAb purification to facilitate and control process performance. Process reagents are considered to be process-related impurities, so demonstration of their clearance is required for the chemistry, manufacturing, and controls (CMC) information submission of an investigational new drug (IND) application (

1

,

2

). These reagents may be classified into two categories: generally recognized as safe (GRAS) reagents and potential safety concern (PSC) reagents (

3

).

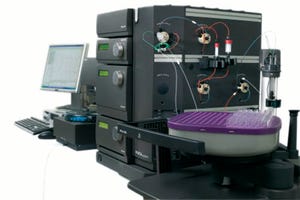

The authors used an ÄKTA Explorer-100 system in their study. GE HEALTHCARE (WWW.GELIFESCIENCES.COM)

GRAS reagents are those defined as inactive ingredients — for intravenous (IV) or subcutaneous (SC) administration only — in FDA- approved drugs (

4

), components of parenteral nutritional therapies (

5

), trace elements with parenteral permissible daily exposure (PDE) ...

https://bioprocessintl.com/wp-content/uploads/2015/05/052015_Allen-optimization.mp3

PALL LIFE SCIENCES (WWW.PALL.COM)

Monoclonal antibodies (MAbs) serve important medical needs in cancer treatment as well as that of autoimmune and infectious diseases (

1

). Antibodies are also widely used in clinical diagnostic assays. They can be coated on solid surfaces to bind specific analytes, conjugated to reporter molecules (either as whole antibodies or fragments) for analyte detection, used in sensitivity panels for lot-release testing, and supplied as positive controls in diagnostic kits (

2

). Our study evaluates the use of hydrophobic charge-induction chromatography (HCIC) for purification of MAbs that are of interest for diagnostic applications. Our objective was to obtain ≥90% purity with ≥90% IgG recovery from a single chromatographic step — a challenging objective with most experiments conducted using feedstock derived from protein-supplemented growth media. To assess the versatility of the HCIC approach, ...

https://bioprocessintl.com/wp-content/uploads/2015/05/13-5-Simon3_TheBoBproject.mp3

The Bolt-on Bioreactor (BoB) project is an independent initiative aimed at developing and commercializing a bioreactor for the automated and efficient culture of adherent cells, especially for application in the production of therapeutic cells and other biopharmaceuticals (

1

). After conducting thorough research on available culture systems for adherent cells, the BoB team believes that a successful alternative to existing devices must answer four major challenges. Addressed in the first article of this series (

2

), the first challenge has to do with

volumetric productivity

. The second installment addressed issues of

automating culture processes

(

3

). This month, the third challenge is addressed. And the final installment will address process economics.

The third challenge is to develop a system in which adherent cells are cultured in a contained chamber, and where contamination risks are minimized even when the sys...

Photo 1: A user-centered human–machine interface creates optimized working sequences, supports and offloads plant operators, and ensures improved plant efficiency.

Today, most plant operators are much more than classic process operators. In addition to operational process control, their range of tasks includes product quality assurance, optimization of resources, and maintenance of high‑throughput rates. Qualified information is necessary to reliably perform those tasks. The human–machine interface (HMI) of a process control system provides visualization. Siemens regards new HMI concepts such as advanced process graphics (APG) as the key to task‑specific or situation‑specific decision‑making (Photo 1).

Graphics Monitor: the Process Window

Before computer technology found its way into control rooms, the window into a manufacturing process was provided in part by huge switching and display panels. Process value displays were grouped according to their importance and tasks of operating teams. Back then, oper...

By 2016, the global pharmaceutical industry is expected to generate an estimated 30% of its total sales in emerging markets (

1

). After India and China, southeast countries such as Indonesia, Singapore, Malaysia, Vietnam, and Thailand are especially attractive markets. The Association of Southeast Asian Nations (ASEAN) Economic Community (AEC) consists of 10 countries united through regional economic cooperation: Thailand, Myanmar, Laos, Vietnam, Malaysia, Singapore, Indonesia, Philippines, Cambodia, and Brunei. The ASEAN Community 2015 (AEC 2015) initiative aims to form a unified economic system throughout the region by the end of 2015. In some ways similar to the economic unity of the European Union, the AEC works to develop a single market system for a more equally developed and globally integrated economic region. To that aim, existing trade barriers have been removed or reduced, and standards across a number of sectors have been harmonized.

Outsourcing Biologics

One report projects that demand for b...