Next-Generation Bioprocessing for Meeting Healthcare Challenges: The Role Single-Use Handling Systems Can PlayNext-Generation Bioprocessing for Meeting Healthcare Challenges: The Role Single-Use Handling Systems Can Play

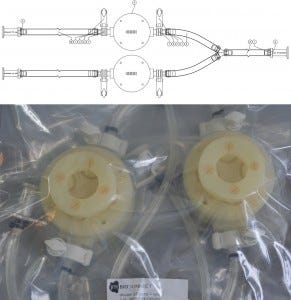

Photo 1: A single-use quaternary pump chamber (Quattroflow) coupled with genderless connectors (AseptiQuik, CPC) for sterilemanufacturing systems

The rapid spread of contagious and lethal diseases worldwide has driven bioprocess suppliers to develop technologies for use in producing disease treatments and vaccines. Bioprocessors need to develop new biologics as well as rapid and reliable methods for bringing those treatments to commercialization. Implementing modular process solutions and single‑use handling systems in closed‑manufacturing processing is one approach to addressing those needs.

Developing and discovering solutions for meeting global healthcare conditions is an evolving part of bioindustry. As points of reference, vermin control and improved sanitation were keys to fighting plagues of centuries past. Penicillin successfully treated pneumonia during the world‑war eras. And virus‑based vaccines that treated diseases such as polio opened the door to prevention through enhanced immunity. Drugs and vaccines produced in large‑scale processes have led to the success of some of the world’s largest pharmaceutical companies.

But new diseases are continuously challenging biomanufacturers. And some well‑known pathogens can gain immunity from existing treatments. The worst combination that the health‑science community prepares for is an infectious disease that is both highly contagious and extremely lethal.

The foundational key to combating disease is fast development and deployment of proper medical solutions. Currently, needed drugs are taking too long to develop, and solutions often are too late for first advances of new pathogens. Much of that delay is related to regulatory compliance. But traditional (small‑molecule) pharmaceutical processes — although they always remain crucial to the health sciences — can fall short in their ability to respond technically when rapid development and deployment of new solutions are needed.

Single-Use Pump Solutions

Biopharmaceutical process systems comprise many components, including bioreactors, filtration and separation technologies, and instrumentation for large‑scale established processes that are as evolved as single‑use modular and closed‑manufacturing solutions. An essential part of the process is moving fluids processes and from one unit operation to the next in a rigidly prescribed manner.

Many processes require very precise flow with low shear and pulsation. Such is the case with certain filtration processes that would otherwise not work. For example, over the past decade, pump technology has evolved, and (although all equipment is essential for process success) single‑use pump technologies such as quaternary diaphragm pumps (Photo 1) have been key bioprocess enablers. Such components have made both development of new drug treatments and acceleration of their production schedules possible.

Regulatory agencies, certification bodies, and industry associations have gained confidence in the efficacy and safety of single‑use solutions. Such technologies are addressing bioindustry needs for product development and speed to commercialization at sufficient scale to meet demand. But bioprocessors remain concerned over reducing the risk of particle release from process equipment. Biopharmaceutical companies have confirmed that with an emerging class of pumps (the quaternary diaphragm pump) particulate release is below measurable levels compared with traditional fluid‑transfer solutions. An independent assessment of a quaternary diaphragm pump and a peristaltic pumping system showed no detectable particles from the quaternary diaphragm pump and a measurable level of particles from the peristaltic pumping system.

In its simplest form (but with vast implications), single‑use pump technology is an example of process equipment that can be supplied either clean or sterile. Such pumps can be used in production runs or campaigns without requiring cleaning until completion. Thus, their design is optimized for matching lifespan to meet sustainability goals.

Quaternary Diaphragm Pumps |

|---|

For some cases, the solution to meeting strict single-use pumping requirements that are demanded in the biopharmaceutical industry is the implementation of positive-displacement quaternary diaphragm technology. The main advantage of using quaternary diaphragm pumps is their unique form of operation: Quaternary diaphragms are driven one after another by a connector plate, which moves back and forth out of its central position in a stroke that is generated by an eccentric shaft. The length of the stroke is determined by the angle of eccentricity. In basic terms, this pumping technology models the operation of the human heart, with its four pumping chambers and check valves that keep product flow constantly moving forward. Many quaternary diaphragm pump chambers contain no rotating parts that can be subject to friction. So there is no operational heat buildup that can compromise products. This mode of operation also means that pumps can run dry, are self-priming, and produce little or no shear because of low slip. They provide low-pulsation, leak-free operation. Quaternary diaphragm pumps can provide constant flows from 1 L/h (0.0047 gpm) to 20,000 L/h (88 gpm). This turn-down capability and range for a quaternary diaphragm pump is unique in the industry. As biologics go from development to clinical trials and then to commercialization, proper scale-up is essential. The same pump technology in a lab needs to handle flow rates as low as 1 L/hr (0.0047 gpm), as well as commercial production flow rates of 20,000 L/hr (88 gpm) or more. This scale-up capability assures that a pump’s operation does not adversely affect repeatability and production rates. Using a single-use quaternary diaphragm pump enables manufacturers to optimize cost of cleaning and validating their pumps. That can lead to quicker production processes without risk of cross-batch or cross-product contamination. |

The Big Healthcare Picture

Single‑use technologies have revolutionized biopharmaceutical manufacturing, process lines, and just‑in‑time supply in general manufacturing through the past century. Ultimately, it is the combination of advanced science and process sytems that enable production of final products that cure diseases. For example, Niels Jerne, Georges Kohler, and Cesar Milstein were awarded the 1984 Nobel Prize in Medicine for their work on the development and control of the immune system and discovery of principles related to producing monoclonal antibodies (MAbs). But their creations became beneficial to humanity only because of supporting developments in basic tools of discovery and production. Perhaps inventors of new single‑use technologies such as filters, connectors, and pumps don’t get much acclaim, but their contributions do play a crucial role in disease treatment.

Photo 2: Hybrid stainless-steel modular chromatography system for biologicals production (COURTESY OF QUATTROFLOW AND CPC CHANNEL PARTNER, HOLLAND APPLIED TECHNOLOGIES)

For decades, the pharmaceutical industry flourished with large, stainless‑steel systems to develop new chemical formulations (Photo 2). Until only recently, the most prominent way to produce viral vaccines was by growing viruses in eggs, then extracting them through processes using stainless steel equipment. Additionally, the best way to treat cancers was by the brute force of chemotherapy and radiation. With perhaps oversimplification, thanks to the evolution of the biopharmaceutical industry, the dependence on growing viruses in eggs and the brute application of chemotherapy and radiation as sole treatments have fallen behind the needs for ensuring human health and the progress of human ingenuity.

Large stainless‑steel pharmaceutical complexes continue to play an important role in supplying pharmaceutical products. Traditional small‑molecule chemical reactions are scaled up from development laboratories to large dedicated stainless‑steel process facilities. Classical pharmaceutical manufacturers have and continue to flourish with robust product pipelines. But as chemically produced products come off of patent protection, generics step in, thus indicating maturity of this industry subsegment.

Massive research in cell biology has elucidated cell structures and led to development of compounds impossible to manufacture using chemical production processes. Although biological cells assume (in a microscopic scale) the same role as large‑scale factories, these factories cannot produce complex substances such as antibody‑drug conjugates (ADCs) like cell “factories” can.

Cell structures can be considered as “factories” that create medical treatments for current global threats such as Ebola. Biomanufacturers including GlaxoSmithKline, Merck, Tekmira, and Medicago are producing remedies for that and other current world health crises. For example, Medicago is creating VLPs to take the place of viruses (without using chicken eggs) for producing immune effects.

Biological cells also produce “tools” that help deliver treatments to target locations. In the battle against cancer, for example, traditional chemotherapy has the effect of killing off cancer cells, but it also kills nondiseased cells at the same time, which weakens patients in such a way that treatments can be detrimental to a full recovery. In response, the biopharmaceutical industry has created ADCs as a new class of drugs. ADCs elevate the effectiveness of treatment by allowing a monoclonal antibody (MAb) to act as a medical “tool” that is linked to a potent small molecule. ADCs have the unique ability to find and then target and kill a cancer cell while not affecting healthy cells. The biopharmaceutical industry continues to produce biologics in other areas using methods such as “cell factories” through advanced scientific applications.

Brief Evolution of Single-Use Technology

Bioprocessing must take place in controlled environments to properly extract, filter, and refine finished products such as MAbs, VLPs, and ADCs. The basic equipment for process fluids required by chemical reactions and product extractions in a pharmaceutical process are the same as those used in many bioprocesses for cell‑derived products. Such products include tanks, reactors, pumps, valves, tubes, instruments, filters, and separators. When technology suppliers first started developing those products for bioprocessing, their natural inclination was to adapt existing technologies for the pharmaceutical industry and adapt them to biopharmaceutical processes.

A good example of such adoption would be permanent stainless‑steel process lines, which required frequent cleaning or sterilization. But as manufacturing processes incrementally evolved, the bioindustry developed very specific needs. During that time, a sizable gap became evident between the needs of new processes and outdated methods, tools, and equipment.

For example, cleaning permanent (stainless steel) installations presents technical, cost, and reliability difficulties. Biological processes require hygienic environments to grow cells and microorganisms. But process environments are prone to contamination from adventitious agents. From this concern, the single‑use concept was developed. Rather than validating processes for cleaning equipment with a large number of variables and risks involved, manufacturers instead can implement sustainably produced equipment by replacing stainless steel with plastics. Applications included pumps, single‑use bioreactor vessels, tubing, and respective connectors. Quaternary diaphragm pumps and single‑use tubing connectors are examples of such equipment meeting bioprocess requirements and single‑use manufacturing concepts (Photo 1).

Photo 3: A single-use assembly from design (top) to prepackaged sterile pump and flow-routing assembly (bottom); photo courtesy JM BioConnect

Benefits of Single-Use Pumps, Mixing Systems, and Connectors

By definition, single‑use devices such as a pump chambers are designed for one production campaign and then discarded and replaced with new components that are certified clean or sterile, as required. It is less costly to ensure that a new component or system is clean and sterile than to validate the same for previously used, contaminated, or even damaged hardware. The high cost of requalifying equipment starts with expensive processes to validate cleanliness, from the mechanics of cleaning to the ancillary costs of water and cleaning chemicals and respective decontamination and disposal.

Because single‑use pumps are used for only one specific purpose before they are discarded, compelling results come from comparing the costs incurred between cleaning previously used equipment and buying and installing new equipment. Such analysis would take into account the type of plastic material and how it is made and disposed of. For example, the base material used in single‑use pump chambers is derived from natural gas, an abundant raw material. Instead of it being used right away as an energy source, the gas is converted to polypropylene and formed into a single‑use pump chamber. After the material is used in a process, it is environmentally decontaminated and completely disposed of by using this material as an energy source. Industry leaders are looking at standardizing the energy‑use process in cement factories, which are generally local to process facilities and traditionally high‑energy users. Although the economics between cleaning old and buying new are not simple, for reasons outside the scope of this article, the savings are sufficient enough for single‑use technology adoption in the bioindustry.

Single‑use technologies have evolved to enable success economically, and commercially. Biopharmaceutical companies are being recognized as “coming to the rescue” in the development of drugs that can battle Ebola and other diseases. Such companies are now using single‑use system filters from suppliers such as Pall, Sartorius, and EMD/Merck Millipore, and they are relying on components such as Quattroflow single‑use quaternary (four‑ piston) diaphragm pumps (from PSG, a Dover company), CPC connectors, and Gemu valves to provide on‑going process solutions.

Advancements in single‑use pumps offer many more benefits than cost efficiency. Such developments include enabling speed to a challenge, speed to market, closed manufacturing, flexibility, considerable reduction of high clean room floor space, and geographic proximity/mobility.

Photo 4: Stainless steel modular columnpacking system contains single-use modules (not shown) for biopharmaceutical production (PHOTO COURTESY OF QUATTROFLOW AND CPC CHANNEL PARTNER, HOLLAND APPLIED TECHNOLOGIES).

Permanent stainless‑steel process systems are inherently inflexible. That is very evident in R&D and drug‑development process applications for which constant reconfiguration is needed. With single‑use components, manufacturers can take a building‑block approach to develop processes that meet development and production capacity nees. This gives them an accelerated ability to develop a solutions to challenges and shorten times to product commercialization. But in certain cases, hybrid systems (both stainless steel and single use modular sub systems) make sense, depending on process economics and scale (Photo 4).

Fast and reliable scale‑up an essential part of meeting market needs. Because flow rate (established by pumps) defines scale, quaternary diaphragm pumps become relevant. Such pumps have a turndown ratio (the difference between maximum effective low‑speed and high‑speed operation) of 200:1 and cover the entire range of flows from 1 L/h to >20,000 L/h. That is not possible with other pump technologies that do not pulsate and that may have only a 10:1 turndown ratio at best.

Further advancements in single‑use fluid‑handling solutions are supporting the growing use of closed‑manufacturing processes. Closed manufacturing involves separation between internal process lines and outside environments where processes are located. In practical terms, less floor space or a lower‑classification cleanroom is required than for traditional “open” systems. Closed manufacturing is difficult to achieve with permanent stainless‑steel processes because it is difficult and time‑consuming to keep connection ports sterile both before and after they are joined.

For a stainless‑steel–based tubing setup, disconnected ports could not be initially sterile and would achieve a proper level of sterility only when completely connected after having undergone a lengthy steam‑sterilization process. This condition severely limits process capabilities and flexibility.

Single‑use sterile connectors make it possible to bring previously sterilized components equipped with them and assemble those components to form a completely sterile system. Using those connectors on quaternary diaphragm pumps further extends that capability to single‑use pumps and mixing systems (Photos 3 and 4).

Once those components or subassemblies are sterilized, then their internal fluid paths are protected from contact with outside (room) environments, thereby enabling closed manufacturing. The resulting impact is profound: Requirements for and use of cleanroom space (considered expensive manufacturing real estate) are greatly reduced. That lowers the cost and complexity of executing new biological processes. Expectations are that closed systems will allow some processes to be moved to geographical areas that are unable to support a larger‑scale open process but can readily accommodate smaller‑scale closed processes for manufacturing customized medical treatments.

A Role in Health Advancement

Health science advances through biotechnology have improved quality of life and enabled biomanufacturers to address emerging health threats and diseases. The latest chapter in this saga has included advances in processes made possible in part by adoption of single‑use pumping solutions, connectors, and associated hardware. In turn, such components make possible the implementation of closed‑process systems that will further expand options, capabilities, and speed‑to‑market capabilities. On the component level, single‑use pumps, mixing systems, and connectors can all play a critical role in further advancing future paradigms.

Corresponding author Wallace Wittkoff is the director of global segments and key account management for PSG, a Dover company; 1-502-905-9169; Wallace.wittkoff@psgdover. com; www.psgdover.com. John Boehm is the bioprocessing business unit manager for CPC (Colder Products Company), a Dover Company; 1-651-603-2537; john.boehm@cpcworldwide. com; www.cpcworldwide.com.

You May Also Like