- Sponsored Content

Adsorption Study of Polymer-Modified Cellufine CEX ResinAdsorption Study of Polymer-Modified Cellufine CEX Resin

August 10, 2016

Sponsored by JNC

Cellulose is well known as a natural raw material that has mechanical strength, lower nonspecific adsorption, and good biocompatibility. In addition, cellulose particles have unique pore-size characteristics appropriate for chromatography of biopharmaceuticals. Ion-exchange chromatography (IEX) is an important step for biopharmaceutical manufacturing. Specifically, cation-exchange chromatography (CEX) can be used as a capture step in monoclonal antibody (MAb) purification. Recently, advanced IEX resins have been developed using polymer modification techniques. Initial screening of conditions such as pH and ionic strength is important for IEX resin. The objective of this study is to reveal the differences of adsorption properties in polymer-modified, cellulose-based CEX resins.

Cellulose is well known as a natural raw material that has mechanical strength, lower nonspecific adsorption, and good biocompatibility. In addition, cellulose particles have unique pore-size characteristics appropriate for chromatography of biopharmaceuticals. Ion-exchange chromatography (IEX) is an important step for biopharmaceutical manufacturing. Specifically, cation-exchange chromatography (CEX) can be used as a capture step in monoclonal antibody (MAb) purification. Recently, advanced IEX resins have been developed using polymer modification techniques. Initial screening of conditions such as pH and ionic strength is important for IEX resin. The objective of this study is to reveal the differences of adsorption properties in polymer-modified, cellulose-based CEX resins.

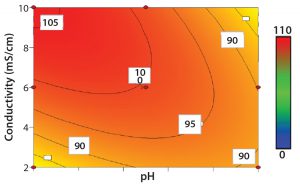

Figure 1A: Contour plot analysis for optimal adsorption condition in Cellufine MAX GS resin

Screening for Optimal Adsorption Conditions with Cellufine CEX Resins

Cellufine MAX S-h (dextran modification) and Cellufine MAX GS (graft polymer modification) resins were used for the study. Dynamic adsorption capacity (DBC) with polyclonal antibodies was examined to draw the contour plot for analyzing optimal condition of pH and conductivity.

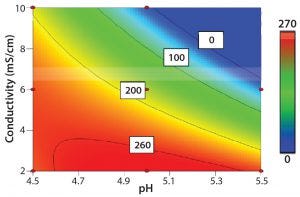

Figure 1B: Contour plot analysis for optimal adsorption condition in Cellufine MAX S-h resin

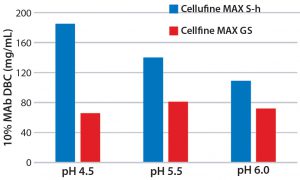

Contour plots analysis showed there were significant differences in optimal adsorption condition between Cellufine MAX S-h and Cellufine MAX GS resins (Figures 1a and 1b). Further DBC was examined with MAb to know adsorption performance under different pH conditions (Figure 2). Cellufine MAX S-h resin was suggested to need careful preexamination in pH and conductivity condition for higher adsorption capacity.

Figure 2: MAb DBC with Cellufine CEX resins; column = 5 mm x 2.5 cmL, loading buffer either 10 mM Na with acetate at pH 4.45 and 5 mS/cm or MES NaOH at pH 5.5/6.0 and 5 ms/cm, residence time = 4 min

Especially pH and conductivity around mild pH (such as pH 6–7) will significantly influence DBC in Cellufine MAX S-h resin. On the other hand, Cellufine MAX GS resin was less susceptible to pH and conductivity for adsorption. According to Figure 2, Cellufine MAX GS resin showed only slight difference of MAb DBC between pH 4.5 and pH 6.0 conditions. This means Cellufine MAX GS resin is expected to be applied to a broad range of conditions in MAb purification, especially in mild pH condition preferred for protein stability.

Acknowledgment

This research is partially supported by the developing key technologies for discovering and manufacturing pharmaceuticals used for next-generation treatments and diagnoses both from the Ministry of Economy, Trade and Industry, Japan (METI), and Japan Agency for Medical Research and Development (AMED).

Shigeyuki Aoyama is a manager of JNC Corporation, Chiyoda-ku, Tokyo, Japan; [email protected]; www:jnc-corp.co.jp/fine/en/cellufine.

You May Also Like