- Sponsored Content

Simplify and Intensify Cell Culture: XCell™ ATF Systems for Cell Culture Process Intensification Now Available in Single-Use FormatSimplify and Intensify Cell Culture: XCell™ ATF Systems for Cell Culture Process Intensification Now Available in Single-Use Format

August 11, 2016

Sponsored by Repligen

A finalist for the 2012 BPI Technology of the Decade Award, XCell™ ATF systems consistently yield high cell retention, concentration, and viability, enabling efficient and productive perfusion and N – 1 perfusion as well as cell banking and seed-train cell culture operations.

A finalist for the 2012 BPI Technology of the Decade Award, XCell™ ATF systems consistently yield high cell retention, concentration, and viability, enabling efficient and productive perfusion and N – 1 perfusion as well as cell banking and seed-train cell culture operations.

Figure 1: Scalable from laboratory to production: XCell™ ATF systems include the device and controller. XCell™ ATF single-use device (left) are available in two sizes. XCell™ ATF stainless steel device (right) are available in five sizes.

XCell™ ATF devices are now available in single-use format, in addition to stainless steel. The new single-use devices deliver 100% cell retention and laboratory-to-production scalability like their stainless steel counterparts but without the need for autoclave sterilization and lengthy setup times.

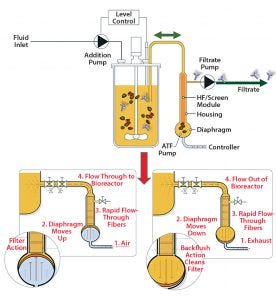

Figure 2: Alternating tangential flow (ATF) technology: XCell™ systems use ATF technology created by the action of a diaphragm moving upward and downward within a pump head, connected to a filter housing and attached to a bioreactor.

Features and benefits of XCell™ ATF Systems include

Continuous, provides clarified harvest ready for capture chromatography

Efficient, delivers 100% cell retention to increase productivity

Intensified, generates high cell concentration and viability

Flexible, connects to any bioreactor and can be used in a range of applications

Gentle, reduces cell stress, increases cell viability, and productivity

Easy to use, single-use reduces setup time and documentation

Scalable, adapts from development scale to production scale

Self cleaning, pump action reduces hollow-fiber filter fouling and increases throughput

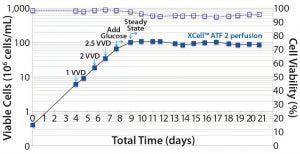

Figure 3: Continuous processing; high cell density with high viability perfusion at 100E6 cells/mL was achieved using an XCell™ ATF 2 system.

Learn more at www.repligen.com.

Rachel Goodrich is senior director of marketing at Repligen, 41 Seyon Street, Building 1, Suite 100, Waltham, MA 02453; [email protected]; www.repligen.com.

You May Also Like