- Sponsored Content

TOYOPEARL® AF-rProtein A HC-650F: Economic Advantages of Using a High Capacity Protein A ResinTOYOPEARL® AF-rProtein A HC-650F: Economic Advantages of Using a High Capacity Protein A Resin

August 10, 2016

Sponsored by Tosoh Bioscience

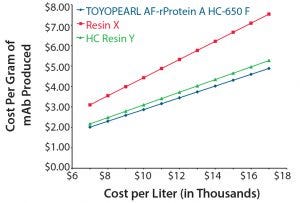

TOYOPEARL AF-rProtein A HC-650F and two other commercially available protein A resins (one of them also a “high capacity” resin) were compared on a cost-per-gram of monoclonal antibody (mAb) produced basis at multiple resin prices from $7,000 to $17,000 per liter as well as three different column configurations. For in-depth comparison, the median resin price of $12,000 per liter was used as a basis to determine comparative production costs among the three resins tested. The configuration used to model what the resin costs would be per gram purified was a column that was packed to have equal column dimensions of 36 cm ID × 15 cm.

TOYOPEARL AF-rProtein A HC-650F and two other commercially available protein A resins (one of them also a “high capacity” resin) were compared on a cost-per-gram of monoclonal antibody (mAb) produced basis at multiple resin prices from $7,000 to $17,000 per liter as well as three different column configurations. For in-depth comparison, the median resin price of $12,000 per liter was used as a basis to determine comparative production costs among the three resins tested. The configuration used to model what the resin costs would be per gram purified was a column that was packed to have equal column dimensions of 36 cm ID × 15 cm.

Figure 1: Columns of equal dimensions

For this evaluation, the following values were held constant: residence time = 3 minutes; dynamic binding capacity (DBC) = 3 minute residence time (from product literature); column load = 80% of stated DBC; harvest titer = 3 g/L; harvest volume = 2,000 L; column lifetime = 100 cycles; column yield = 95%.

As shown in Figure 1, at a column capacity of about 732 g/ load, the TOYOPEARL AF-rProtein A HC-650F had the highest load capacity of the three resins packed at an equal column dimensions of 36 cm ID × 15 cm. The cost per gram of antibody purified was also lower than the other two resins at every similar price point.

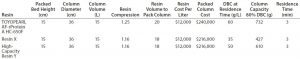

Table 1

Conclusion

As can be seen by comparing Tables 1 and 2, making use of a high capacity protein A resin in your purification process is an excellent way to save on production costs.

Table 2

At the median resin price of $12,000/L, the TOYOPEARL AF-rProtein A HC-650F resin would save customers almost $2.00 per gram of antibody produced over a resin with a capacity of 35 g/L and almost $0.50 per gram over a competitive high capacity resin.

With increasing pressures on producers of biopharmaceutical drugs to reduce productions costs, the use of a high capacity protein A resin is a superior way to achieve this goal without making any sacrifice to product quality or processing time.

R. Christopher Manzari is the Product Manager, Process Media at Tosoh Bioscience LLC, 3604 Horizon Drive, Suite 100, King of Prussia, PA 19406; 1-484-805-1219; [email protected]; www.tosohbioscience.com. Tosoh Bioscience and TOYOPEARL are registered trademarks of Tosoh.

You May Also Like