Introduction: Viral Clearance and Inactivation in Downstream ProcessingIntroduction: Viral Clearance and Inactivation in Downstream Processing

December 12, 2022

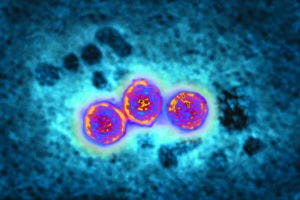

On the Cover: Hepatitis B is an example of a lipid enveloped DNA virus. It is one of the smallest such viruses, with a virion diameter of 42 nm. (HTTPS://WWW.ALAMY.COM)

Viral safety in the biopharmaceutical industry is both an upstream-production and downstream-processing concern. Companies must take a multipronged approach using orthogonal methods that are validated to prevent viral contamination or to remove it from biologic drug products. On the upstream side, the focus is on prevention through risk assessment and mitigation. That begins with environmental control of facilities and includes both careful selection of raw materials and cell lines and preparatory filtration of culture media components.

In downstream processing of drug substances, the focus is on inactivation and clearance of viruses that may be present. For inactivating and killing viruses, important technologies include high-temperature, short-term (HT/ST) and solvent/detergent (S/D) treatments of process streams. Virus removal can be effected through purification methods, typically using depth and tangential-flow filters and/or chromatographic columns.

In This Special Issue

The contributors to this featured report focus their discussions on downstream operations. First, two consultants with Parexel (one of whom is a former FDA laboratory chief) provide an update on the Triton X-100 issue in Europe. Serving as the detergent in S/D viral inactivation treatments, the familiar surfactant is especially important to processing of blood plasma products. It is also used as an excipient in some product formulations and has been designated by the European Union as a substance of concern. Because of related reproductive and other toxicity considerations, companies are evaluating how to phase out their Triton X-100 use. In some cases, that will necessitate manufacturing process changes.

Our second article reports on the results of a benchmarking survey by the BioPhorum Development Group’s viral clearance workstream. Over a dozen leading biopharmaceutical companies were asked about operating parameters they considered to present worst-case conditions. Authors from Alexion, Bristol Myers Squibb, Genentech (Roche), Janssen, Lonza, Merck, Novartis, and Sanofi assess whether companies evaluate process parameters according to clinical trial stage or commercialization status of biological products in development. Although studies supporting biological license applications (BLAs) tend to be more conservative — testing more worst-case parameters overall — than those supporting investigational new drug (IND) applications, results indicate only minimal differences in how companies approach viral clearance studies throughout product development.

Finally, authors from Bristol Myers Squibb describe their study of a hollow-fiber nanofiltration method for clearance of viruses from antibody-derived molecules without Fc structural components (required for protein A affinity capture chromatography). After reviewing the range of available virus filtration options, the team presents its reasoning for selecting a specific technology for a bispecific antibody candidate.

Cheryl Scott is cofounder and senior technical editor of BioProcess International, part of Informa Connect Life Sciences, 1-212-600-3429, [email protected]; http://www.bioprocessintl.com.

You May Also Like