Automated Liquid Handlers As Sources of Error March 2009Automated Liquid Handlers As Sources of Error March 2009

March 1, 2009

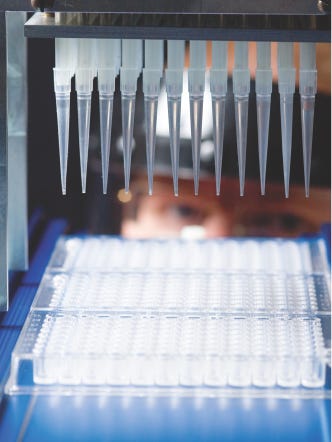

Use of automated liquid handling equipment for rapid testing and reproducible screening of thousands of molecules, cells, and compounds has become an essential component of life-science laboratories across the globe. Along with an increase in such use, transferred volumes have shrunk, as demands increase on transfer accuracy and precision when aspirating, diluting, dispensing, mixing, and washing. Automated liquid handlers are generally used to increase the productivity and repeatability of volume transfer, but as discussed here, they are still prone to error. So it is important to understand how some errors can be recognized and prevented to maintain liquid handling quality assurance, especially when transferring critical reagents.

PRODUCT FOCUS: BIOLOGICS AND OTHER PHARMACEUTICALS

PROCESS FOCUS: PRODUCT AND PROCESS DEVELOPMENT

WHO SHOULD READ: QA/QC, R&D, AND ANALYTICAL PERSONNEL

KEYWORDS: ASSAY DEVELOPMENT, HIGH-THROUGHPUT SCREENING, AUTOMATION

LEVEL: BASIC

Because concentrations of biological and chemical species are volume dependent, the accuracy and precision of individual (stepwise) volume transfers directly affect the amount of critical reagent transferred to or from an assay. Inaccurate or imprecise delivery can easily result in the loss of experiment integrity. Therefore, knowing the exact volume in each step of an assay as well as the component concentrations involved is critical to interpreting results. This allows data and process integrity to be maintained.

How Automated Liquid Handlers May Contribute Error: Automated liquid handlers can take the human variable (the largest source of error we’ve identified in manual pipetting) out of pipetting and thus offer more repeatability (1). These systems, however, are subject to their own types of error because they are much more complex than manual pipettors and have many internal actions, all of which must work within specification. The very selling point of many systems — their flexibility and control over many variables in an automated pipetting process — inherently leads to more opportunity for error.

Economic Impact of Liquid Handing Error: If automated liquid handlers do not dispense the desired amount of critical reagent(s), then unseen errors are likely to propagate increasingly as a process continues. Even slight discrepancies in the amount of transferred reagent can compromise assay results, leading to poor-quality, useless data and downstream costs associated with remedial actions. The economic impact of allocating resources for a liquid handling process that is based on potentially false results may be severe. Moreover, if a liquid delivery system is over-delivering target volumes of expensive and/or rare reagents, then there will be a significant cost for the loss of precious materials.

ANDREI TCHERNOV (WWW.ISTOCKPHOTO.COM)

A typical high-throughput screening laboratory might test 1.0–1.5 million wells per screen on average about 20–25 times per year. With an approximate cost of $0.10 per well, the cost for reagents is thus about $3.75 million per year (1.5 million wells × 25 screenings × $0.10/well). Liquid handlers continuously over-dispensing critical reagents can easily lead to an average cost per well of, say, $0.12 per well (a 20% increase) leading to an additional annual cost of $750,000. A company with such a problem risks depletion of those rare compounds and may not even have enough to conduct a full retesting program.

Furthermore (and depending on the type of screening effort), over-dispensing critical reagents in each assay may cause more false positives, which leads to subsequent screenings. False positives are not fatal to a process, but they are detrimental and will cost a laboratory time, resources, and materials to continue screening false performers until those are tested out.

On the other hand, under-delivering critical reagents can lead to an increase in false negatives, which can be severely detrimental to the integrity of an entire screening process. To screeners, a false negative is no different than a “nonperformer,” and such compounds would not advance to subsequent screenings. So if critical reagents are under-delivered, the next blockbuster drug could go unnoticed and potentially cost a company billions in future revenues.

Error Sources

Tip Types and Contamination: The types of tips used on a liquid handler are critical to the accuracy and precision of each volume transfer it performs. Some of these automated systems use fixed (permanent) tips (including pin tools) to mitigate the recurring consumable costs required for disposable tips. However, there must be rigorous and effective tip-washing protocols in place for such systems. Otherwise, unwanted residual reagents could be carried over and contaminate subsequent transfer steps. Ineffective tip washing can thus cause liquid handling errors, so users should have validation protocols to prove the efficiency of washing methods to ensure that fixed tips are clean and the entire sample plug is removed each time.

With disposable tips, the types used are very important to the integrity of volume transfer. Vendor-approved tips (rather than the cheaper “bag of tips” option) should always be used to minimize volume-transfer errors and optimize liquid delivery. Tip performance has been found to be directly related to quality because tip material, shape, properties, fit, and wettability are all important factors for repeatable assays. Cheaper bulk tips may not be manufactured with the highest-precision manufacturing processes and thus may have variable characteristics that affect delivery, such as differences in their upper diameters, virgin plastic content, and presence of residual plastic residue inside (flash). Such tips also might not fit well on a liquid handler, and they can have variable wetting/delivery properties. When approved tip types are not used, accuracy and precision may be at risk. In some cases, liquid handlers may be incorrectly blamed for variable performance when the pipetting tips are the true root cause of error.

Contamination is another source of error when using automated equipment. For instance, a liquid handler gantry/head moves across the robot deck, aspirates reagent, moves to a predetermined deck location and dispenses reagent or aspirates another reagent, then moves to a different location and dispenses, ejects, or washes tips, and so on. Contamination can occur while the head is moving across the workspace, where droplets can fall from pipette tips onto the deck workspace, especially when slippery or organic reagents are involved. Users should evaluate their systems and tips to ensure that droplets are not remaining after samples are dispensed. Some companies address this possibility by adding a trailing air gap that follows reagent aspiration to minimize the chances of liquid slipping out of the tip. To ensure that contamination is not caused by random reagent splatter onto the deck workspace, users should also carefully plan when and where disposable tips are ejected.

Sequential Dispensing Inaccuracies: In some liquid handling protocols, a relatively large volume of reagent is aspirated and then sequentially or systematically dispensed across a microplate. Although this method can save time, sometimes it can involve variable accuracy errors. To prevent contamination or dilution users must ensure that, upon dispensing, pipette tips are not touching any liquid in microplate wells. It is usually recommended that these protocols involve a dry dispense (reagents dispensed into dry wells) — or alternatively, reagents can be dispensed without direct contact, from above buffer-filled wells. If an automation method involves sequential transfer, the user should validate that the same volume is dispensed in each successive transfer because it is common for the first and/or last dispense to transfer slightly different volumes.

Serial Dilution Transfers: Many laboratories perform some type of dilution testing to determine various characteristics associated with specific assays, such as dose-response, toxicity, detection limits, percent inhibition, and drug efficacy. A serial dilution is a systematic assay or test process in which an important reagent is sequentially reduced in concentration. These assays are predominantly carried out using microplates with different rows (or columns) containing sequentially lowered amounts of critical reagent across each plate. In many such applications, a neat or diluted target reagent will be transferred to a column of wells containing a predetermined volume of assay buffer.

For example, 100 µL of neat target reagent could be transferred to a column of wells in a 96-well plate, each of which already contains 100 µL of assay buffer. The resulting 200 µL total volume is then mixed with aspirate/dispense cycles or through on-board shaking before 100 µL of the resulting 50% less-concentrated target reagent is aspirated and transferred to the next column of wells, which also already hold 100 µL of buffer. This specific example is a 1:2 dilution and may occur with up to twelve steps across a the 96-well plate to dilute the starting material to a final concentration of ½12 or ¼,096 of the starting concentration, depending on whether columns or rows form the serial basis.

Automated liquid handlers are routinely applied in serial dilution protocols, and users need to verify that that these volume transfers are accurate and that each well is efficiently mixed before the next transfer takes place. If reagents in the wells are not well mixed — and therefore not homogeneous before transfer — the concentration of critical reagents will be very different from the assumed theoretical concentration levels across the plate. Experimental results will be flawed, and users may have no indication that inefficient mixing is to blame.

Pipetting Methods and Method Parameters: One of the first steps in minimizing error in automated liquid handling is to choose the right pipetting technique (e.g., forward-mode or reverse-mode pipetting). The most common technique is forward mode, in which the entire aspirated reagent in each pipette tip is discharged. Forward mode is suitable for aqueous reagents with or without small amounts of proteins or surfactants.

Reverse mode is a pipetting technique in which more reagent is aspirated into the tip than is dispensed (e.g., if 5 µL of serum is required, the pipettor might be programmed to aspirate 8 µL of serum and then dispense the 5 µL from that, with the theoretical 3 µL remaining dispensed back to a reagent reservoir or to waste). This method is most suitable for viscous or foaming liquids.

Automated liquid handling errors can occur when variables are incorrectly defined within a user interface (software). For instance, users should ensure that procedural variables (aspirate/dispense rates and heights, requested volumes, pauses, liquid class settings, and so on), deck layouts (position and location of consumables and hardware), and consumable types (microplate types/footprints, reagent reservoir sizes, and so on) are properly defined for each assay.

It is also important to maintain a tip depth of about 2–3 mm below the surface of a reagent reservoir when aspirating liquid. Pipetting errors may occur if reagent continues to be removed and tip heights are not being compensated for that difference. In some instances, a liquid handler might use conductive or liquid sensing tips that indicate the liquid surface depth. Errors can occur in aspirating reagent if liquid sensing tips are lowered into bubbly or frothy reagents, when the system can falsely identify liquid being present where it is not.

Risk Reduction

To reduce liquid handling errors, laboratories must implement regular calibration programs and verification checks for volume transfer accuracy and precision and to quickly identify failing systems. Evaluation methods should be standardized, fast, and easy to implement, and they should minimize instrument downtime and required resources. Currently, only one commercially available standardized platform meets these requirements (2,3,4,5,6).

Volume transfer for critical target screening should be compared for all devices within a process, especially for liquid handlers that perform similar or identical tasks. If machines in San Diego and Boston are performing the same tasks for the same assay or assay type, those systems should be evaluated with a standardized procedure for tip-by-tip accuracy and precision. A volume-verification method should also offer the opportunity to understand liquid handler device behavior for quality control purposes, trending patterns, diagnostic troubleshooting, method transfer, factory and site acceptance testing, and employee training.

To maintain analytical integrity by reducing error and associated downstream economic losses, companies should implement volume verification methods of performance evaluation to understand whether critical volumes are being accurately and precisely dispensed. As process control continues to be emphasized, a robust volume verification method should be implemented so that liquid handler behavior is known, optimized, and verified to deliver desired target volumes for all levels of assay development. The volume verification method should serve as an essential tool in all laboratories that use liquid handling methodology because it is hard to manage and minimize error with no means to identify it in the first place. The more frequently liquid handler checks are performed, the sooner malfunctioning liquid handlers will be detected, fixed, and brought back into line.

REFERENCES

1.) Vaccaro, W. 2007. Minimizing Liquid Delivery Risk: Operators As Sources of Error. Am. Lab. News:16-17.

2.) Dong, H. 2006. The Use of a Dual Dye Photometric Calibration Method to Identify Possible Sample Dilution from an Automated Multichannel Liquid-Handling System. J. Assoc. Lab. Autom. 11:60-64.

3.) Bradshaw, JT. 2005. Multichannel Verification System (MVS): A Dual-Dye Ratiometric Photometry System for Performance Verification of Multichannel Liquid Delivery Devices. J. Assoc. Lab. Autom.:35-42.

4.) Knaide, TR. 2006. Rapid Volume Verification in High-Density Microtiter Plates Using Dual-Dye Photometry. J. Assoc. Lab. Autom. 11:319-322.

5.) Albert, KJ. 2006. Verifying Liquid Handler Performance for Complex or Non-Aqueous Reagents: A New Approach. J. Assoc. Lab. Autom. 11:172-180.

6.) Albert, KJ, and JT. Bradshaw. 2007. Importance of Integrating a Volume Verification Method for Liquid Handlers: Applications in Learning Performance Behavior. J. Assoc. Lab. Autom.:172-180.

You May Also Like