Working Toward Animal-Free ProcessingWorking Toward Animal-Free Processing

November 1, 2010

Biological therapeutics is one of the fastest growing segments of the pharmaceutical industry — so much in fact that the overall cell culture media and supplements market used in bioprocessing applications is reportedly near $800 million (1). An increasingly important trend in cell culture is risk reduction throughout the supply chain, including a stringent focus on key raw materials. Accordingly, the industry has increasingly adopted animal-component-free materials to mitigate concerns over safety, transmissible spongiform encephalopathies, and other contaminations.

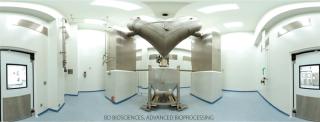

Until recently, such materials have been produced in mixed-use facilities, some with dedicated suites and/or equipment. But concerns over contamination have prompted a few forward-thinking companies to consider building or acquiring stand-alone processing plants. In August, I visited the new 95,000-ft2 site of BD Biosciences–Advanced Bioprocessing in Miami, FL, the first fully dedicated animal-free, antibiotic-free (trademarked AF2) CGMP production facility for commercial cell culture media, peptones/hydrolysates, and chemically defined supplements. Customers can also bring their custom formulations into the facility, manufacture those, and presupplement their media with AF peptones. During my visit, the company shared how the essential elements of the facility’s design, technology, and extensive level of risk mitigation contributed to moving the industry toward providing “low-risk” animal-free products.

Defining Animal Free

In efforts reminiscent of those in which the food industry debated over the definition of organic, so too the bioprocessing industry is working toward a consensus over the conditions constituting true “animal-free” media processing. There is yet no current industry or regulatory standard. “Because there is no definition out there, we advise our customers and clients that they need to understand what a supplier’s policy is as it meets those requirements,” says Mike Titus, PhD, director of quality management and regulatory compliance. “What one supplier considers animal free is not the same definition as another supplier.”

Reaching an agreement is taking some work. At the 2009 BioProcess International Conference and Exhibition in Raleigh, NC, BD Biosciences hosted a discussion forum (“Defining Animal Free for Cell Culture Based Biotherapeutic Production: Aspects and Considerations for Today and Tomorrow”). The panel comprising experts from FDA’s CBER and industry discussed how animal free should be defined. At this year’s BPI Conference, the company hosted a similar discussion that focused on its unique, tertiary-level definition.

The facility’s stringent, tertiary-level requirements go three levels back in the manufacturing process, working with its own vendors to obtain information to ensure that reagents are animal free. For example, at the primary level is an ingredient that goes into BD’s media, the secondary level would be an enzyme used to manufacture that ingredient (a subcomponent), and the third level would be the media used to stabilize and store that enzyme (e.g., skim milk). BD will report on its certificate of analysis (C of A) anything beyond tertiary if known, but control is at the tertiary level at minimum.

To gather this information, BD’s quality group undergoes an extensive review of its raw materials suppliers, which includes an extensive questionnaire and/or audit of their facilities to ensure that the information received is correct and meets its AF policy. Products not certified as controlled to the tertiary level will not enter the facility or be produced. This process is in addition to acceptance testing in BD’s quality laboratory before any raw materials are released for manufacturing to ensure that they meet performance requirements. In addition to performance and safety, having documentation certifying that materials are animal-free at a tertiary level also helps BD’s customers when they are file with regulatory agencies moving forward with their product.

“It’s an extensive assessment because we want to understand whether there are any animal components used in the production of their raw materials. We ask them to go back several steps in the manufacturing process. If there are [animal components], obviously we need to know the nature of those materials and the source of those animals, which opens up a host of other questions,” says Titus.

Achieving an antibiotic-free process (the “2” in AF2) is just as important, although it requires a different strategy and diligence. By designating its facility as antibiotic-free, BD states there is no historical, current, or future antibiotics use within that facility.

The BD Biosciences–Advanced Bioprocessing AF2 production facility in Miami was designed to provide a tertiary-level of safety for cell culture media ()

History And Design

The AF2 designation came into fruition not only because of the design of this site, but also because of its history. William James, director of operations, and his colleagues were quick to point out the various reasons for choosing the Miami location. “First of all, we saw a skilled and experienced workforce, which is essential for any facility.” The biggest driver, however, was the opportunity to purchase an existing plant that was originally designed to manufacture an oncology product but had never gone into production. BD Biosciences was able to retrofit the plant to meet its specific needs. “Not only was this choice more cost effective, but it was better for risk mitigation than adding onto an existing facility,” says James.

Before retrofitting the Miami facility, BD worked with its customer advisory board, comprising experts from eight global biopharmaceutical and pharmaceutical companies. “They are the ones who articulated the need for moving toward an AF2 approach in the early days,” says James. BD asked its key customers what they would like to see in a new facility. Answers emphasized the industry’s general concerns: minimizing and controlling risk, ensuring safety, and establishing and maintaining lot-to-lot consistency.

Moreover, because the Miami plant was a preexisting pharmaceutical facility, it was built to a much higher level of segregation than a standard media manufacturing plant. The design flo

w features two manufacturing sides — one for powders (under negative pressure) and one for liquids (under positive pressure) — that are separate from each other. They are also both separate from personnel entry (unidirectional flow of raw materials, personnel, and products).

Validation And Technology

BD Biosciences is opening this facility in stages as it undergoes validation of its various processes. Validation of a first-of-its-kind site is no small feat. All product-contact materials (including bags, containers, circulated nitrogen gas) are held up to the same tertiary-level AF2 standard. A dedicated quality systems group (headed by senior manager Asiya Imam) starts with a master validation plan and sequentially brings various products and technologies on line.

Currently the facility is open and validated for powdered cell culture media manufacturing, with plans to have liquid media manufacturing for bagged and bottled products online during the first quarter of 2011. Also in 2011, the BD Biosciences will be transferring production of its animal-free peptones from its Baltimore, MD, manufacturing operation to the Miami plant.

Key elements to minimizing risk of carryover and contamination at the new site have included zoned air-handling systems and terminal UPLA filters (on the liquid media side), modular cleanrooms, automated clean-in-place and sanitize-in-place processes, and wash-in-place systems meeting requirements set by the US Pharmacopeia and the European Pharmacopeia. Another critical technological piece is BD’s state-of-the-art pin milling technology (Hosokawa Alpine UPZ pin mill). Pin milling helps maintain particle-size consistency at 95% to ≤212 m to help ensure content uniformity and a homogeneous blending.

During my visit, Jon Wannlund, director of research and development, explained how the selected pin mill technology helps mitigate risk for media production. He explained that pin mills cause less degradation when processing the media components. The media components pass through the mill without being held back by screens. By comparison, a Fitz mill contains a screen that will hold back the components while being pulverized repetitively until they become the right size to flow through the mill. A process containing a screen can generate localized heat at the screen surface. The cooling technology BD uses for the pin mill is a closed-loop recirculation of cooled nitrogen gas. The powder is fluidized and transported from the mill to a collection bin. By surrounding each particle with a controlled environment, it allows for more efficient cooling and the nitrogen prevents any explosion hazard.

Next Step: Chemically Defined Media

Although several biological therapeutic products that use animal-derived components are grandfathered in and will remain on the market for a number of years, most biopharmaceutical companies are developing new products using AF reagents. BD Biosciences’ bioprocessing experts believe this trend will continue toward completely chemically defined formulations such that there are no “undefined” components in the media. “These materials will not only be animal-free, but also chemically defined,” says Imam. “That information will provide the exact composition of the cell culture media and supplements, which will help in the validation and assist customers when they file with regulatory agencies.”

About the Author

Author Details

Maribel Rios is managing editor of BioProcess International, [email protected].

REFERENCES

1.) 2010.BD Biosciences–Advanced Bioprocessing, personal communication.

You May Also Like