Enhanced Capture of a Recombinant Human Growth Factor Using Eshmuno® CPX ResinEnhanced Capture of a Recombinant Human Growth Factor Using Eshmuno® CPX Resin

Eshmuno® CPX resin is a new strong cation exchanger developed using EMD Millipore’s tentacle technology to provide high binding capacity, resolution, and target yield. For process improvement purposes, this resin was applied for capture of rhFGF18, a fibroblast growth factor (expressed in Escherichia coli) in phase 2 clinical development for restoring damaged cartilage surface in osteoarthritis. Early purification work used Resin A at low load (12.3 mg target/mL CV) and moderate flow rate (180 cm/h = 6.7 min residence time, RT). For direct comparison, the Eshmuno® CPX resin was first tested under the same conditions as Resin A. With both resins, rhFGF18 was obtained with high purity and yield (>96%).

Process Improvements

Eshmuno® CPX resin has great potential for process improvements because it can be operated at increased flow rates and high loadings. This resin can be used at RTs as short as 2.4 min at <3 bar net pressure (for a packed bed of 20 × 20 cm and standard process buffers). For low-titer applications (<1 g/L) in particular, high flow rates significantly affect productivity. For Resin A, no residence times <6 min. can be realized (due to flow limitations of the matrix). In a case study, Eshmuno® CPX resin was challenged by running a purification at high loading and elevated flow. Resin B and Resin C (two other commercially available resins that allow for higher process flow rates) were also included in that evaluation.

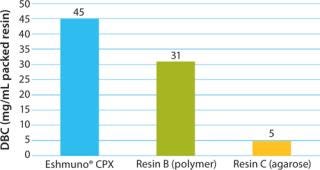

High Dynamic Capacity

Superior dynamic binding capacity at relatively high conductivity was confirmed for Eshmuno® CPX resin. Resin C was significantly less effective under the same conditions.

Figure 1: ()

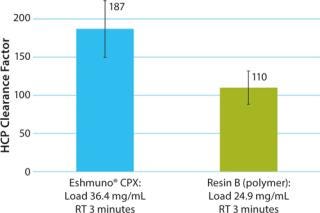

Efficient Host-Cell Protein Clearance

Purification at elevated flow rate and high loading achieved high rhFGF18 purity of 97%. Compared to Resin B, Eshmuno® CPX resin achieved more efficient HCP clearance. The initial high HCP level of 43,000 µg was reduced to 230 µg.

Figure 2: ()

The higher binding capacity of Eshmuno® CPX resin translates directly into a smaller column size. A calculation for producing 1 kg of purified rhFGF18 in a capture step results in a packed bed of 34 L for Eshmuno® CPX resin (50 L for Resin B) with step yields of 82% and 81%, as well as resin loads of 36.0 g/L CV and 24.8 g/L CV respectively. Smaller columns imply cost savings because they require less resin, consume less buffer, and require smaller column hardware.

About the Author

Author Details

A. Stein, A. Heinen-Kreuzig, and A. Kiesewetter are with Merck Millipore, Merck KGaA, Frankfurter Straβe 250, 64293 Darmstadt, Germany; 49-6151-723568; [email protected].

You May Also Like