Mixing and Resuspension of High Powder Loads Using a Magnetic MixerMixing and Resuspension of High Powder Loads Using a Magnetic Mixer

July 1, 2008

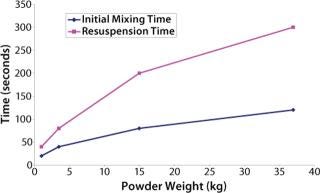

Figure 1.

The Newmix-Levtech Magnetic Mixer system is a compact and noninvasive single-use mixing system. Its heart is a mixing bag that incorporates an innovative, bottom-mounted, magnetically driven impeller capable of providing efficient high-torque mixing for all powder-liquid and liquid-liquid mixing applications. The impeller rides on a low-friction, inert bearing assembly designed to ensure low particle shedding while allowing mixing of very high powder loads in large liquid volumes. All product-contacting surfaces are 100% disposable.

Introduction

Powder-liquid mixing is a common requirement in biopharmaceutical processing. To maximize mixing efficiency for powder-liquid applications, the Magnetic Mixer is available with a large (6.35-in.), centrally located magnetic impeller. In this experiment, a Magnetic Mixer system’s ability to suspend a very high powder load and its resistance to stalling when buried by compacted solid were tested. The powder chosen was diatomaceous earth — a fine, inert, and insoluble powdered filter medium that is light and fluffy when it is dry, yet forms a dense mud when mixed with water.

Experimental

A 200-L Magnetic Mixer mixing bag was filled with ∼160 L of water, and its mixing speed was set to 300 rpm. Diatomaceous earth powder (d = 0.22 kg/L) was then added incrementally to the top of the mixing bag — up to a cumulative added weight of 37 kg. After each addition, the time taken to create a uniform suspension was noted, then the mixer was shut off, and the suspended powder was allowed to settle into a dense, compacted mud at the bottom of the mixing bag. After it had settled, mixing was restarted, and the time to completely resuspend the powder was recorded.

Results

Figure 1 shows initial suspension (mixing) and the subsequent resuspension times as a function of the cumulative amount of diatomaceous earth added. The data demonstrate that even the highest powder load of 37 kg was successfully suspended within only a few minutes. Furthermore, after allowing the powder to settle such that it completely buried the magnetic impeller, the mixer was able to fully resuspend that powder within five minutes. At no time during the experiment did the impeller stall or hesitate. Video of this experiment is available upon request.

Figure 1. ()

Figure 1. Newmix® – Levtech® Magnetic Mixer with M–Mix bag for powder-liquid mixing ()

Conclusions

The Newmix-Levtech Magnetic Mixer system is well suited to powder-liquid mixing applications, even when very high powder loads are anticipated. The Magnetic Mixer is also capable of functioning properly and effectively without stalling even when its impeller is buried under a dense layer of sediment.

You May Also Like