The Cell Therapy Industry Needs High-Quality Healthy-Donor MaterialThe Cell Therapy Industry Needs High-Quality Healthy-Donor Material

Essential considerations for recruiting healthy donors for high-quality cell therapy manufacturing

The cell and gene therapy (CGT) segment has grown tremendously over the past decade. And while the industry deals with a steep learning curve inherent to a rapidly developing field, problems must be solved, and solutions must be reduced to practice. One such problem, long understood by the industry but now thrust into the spotlight, is sample handling: proper collection, processing, preservation, storage, and transportation of cellular starting material. Suboptimal techniques for such logistics have been shown not only to diminish cell viability and product efficacy, but also to introduce significant stumbling blocks to the process of getting new therapies approved (1, 2).

Another crux is that the CGT industry increasingly requires high-quality starting material. Good drug products start with good raw materials, and in no case is that truer than for CGT. Human cells and tissues are the raw materials needed to research and develop next-generation cellular therapeutic drugs. Those materials cannot be manufactured on demand and must be sourced from human donors.

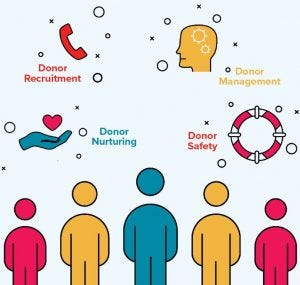

Donor Recruitment Considerations

Cell therapy can be split into two categories: autologous and allogeneic therapies. Autologous therapies use cells sourced from unhealthy patients. After therapeutic alteration, those cells are reintroduced into the same patients to drive therapeutic benefits. These therapies have the advantage of using a patient’s own cells as starting material. Moreover, cell collection and reintroduction can be handled in a single treating facility.

By contrast, allogeneic therapies start with cells from healthy donors. They represent an excellent source for high-functioning target cells, but because collection often is performed at times and locations different from the point of administration, the products must be cryopreserved, stored, transported, and thawed before use.

Cells for either type of therapy are collected during a process called apheresis. Components such as white blood cells are separated at the time of collection, offering a highly concentrated product rich in target cellular material.

Given the complicated logistics involved in developing and commercializing these therapies, access to reliable donors is critical for CGT manufacturers. Many factors must be considered during donor screening and selection. Age, weight, gender, ethnicity, human leukocyte antigen (HLA) type, medical history, and other demographic criteria all should be matched as closely as possible with the client’s study design. It is recommended that backup donors be recruited and screened for each program in case primary donors defer or must withdraw from the process.

Selected donors who arrive at an apheresis collection center must answer a health questionnaire to determine their eligibility. Donors also must be screened rigorously to prevent infectious disease transmission and to ensure that they are healthy enough to donate safely. Once an optimal matching donor is found, cell collection centers must ensure (before securing consent) that a donor fully understands what the process involves and what risk is incurred.

Meeting appropriate screening criteria and having sufficient quantities of cell therapy starting material on hand to meet ongoing clinical trials or manufacturing needs require access to a large, diverse, and reliable donor network. Expert donor management assures that clients will meet project goals on time. Actively recruiting donors and ensuring their wellbeing and safety throughout the process also are vital to maintaining a high-quality donor database. Thus, a robust donor network is a critical asset in meeting raw materials demand consistently as well as a key determinant of downstream product quality.

Preventing Shortages

Given the disparity between sudden, rapid growth in demand for viable cellular starting material and the time it takes to establish a substantial pool of reliable, well-characterized donors, the industry currently faces a significant shortage of capable, premium suppliers. This shortage is likely to impede the CGT industry in the future as the supply of donor material struggles to keep up with manufacturing needs. Considering both the critical impact that starting material quality has on product efficacy, and the criticality of achieving efficacy targets in phase 1 and 2 clinical trials, the urgent need for capable apheresis suppliers cannot be overstated.

References

1 Burger S. Biopreservation Stability Considerations for Cell Therapy Development and Commercialization. BioPreservation Today 1(2) 2009: 4–5; https://www.biolifesolutions.com/wp-content/uploads/2016/01/BPT-Spring_2009.pdf.

2 Clarke D, Smith D. Managing Starting Material Stability to Maximize Manufacturing Flexibility and Downstream Efficiency. Cell and Gene Therapy Insights 5(2) 2019: 303–314; https://insights.bio/cell-and-gene-therapy-insights/journal/articles/managing-starting-material-stability-to-maximize-manufacturing-flexibility-and-downstream-efficiency.

Brad Taylor is global marketing director, and Dominic Clarke is global head of cell therapy at HemaCare, 8500 Balboa Boulevard, Suite 130, Northridge, CA 91325; 1-877-310-0717.

You May Also Like