- Chromatography

- Sponsored Content

Re-Imagining Chromatography: Navigating the Path to Downstream IntensificationRe-Imagining Chromatography: Navigating the Path to Downstream Intensification

Sponsored by Sartorius

Global access to medication is a crucial driver in the pharmaceutical industry (1). Thus, drug manufacturers are encouraged to lower their production costs while increasing productivity to bring affordable drugs to market quickly.

Process intensification is a natural solution for improving facility output. So far, upstream processes have been the main focus of intensification efforts. Combined with high-performing cell lines, those strategies have created higher titers. However, manufacturers now face bottlenecks in their downstream processes, which must evolve to handle the improvements.

Downstream process intensification is an ideal solution for solving such issues. Process intensification can increase yield, decrease process timelines, reduce cost of goods (CoG), reduce footprint, and increase flexibility without making significant changes to process parameters. The relative importance of these drivers will inform the selection of an intensification approach. As the workhorse of downstream bioprocesses, chromatography is the focus of most intensification strategies.

Strategic Considerations for Process Intensification

For established modalities, such as monoclonal antibodies (MAbs), drug developers must try to supply a global demand while keeping up with competition from biosimilars. Therefore, being fast and responsive is critical. Downstream intensification strategies should prioritize flexibility and accelerate time to clinic.

For newer modalities, drug developers need to produce enough active pharmaceutical ingredient (API) when purity and yield are still challenged by relatively novel purification processes and an increasing demand for higher quality by regulatory authorities. But new modalities and platforms can create fresh opportunities for improving innovation and efficiency. Without access to existing platform processes, manufacturers of newer modalities might be more amenable to using innovative technologies to address their needs.

Finally, the increasing spotlight on sustainability in the biopharmaceutical industry (2) is particularly applicable to chromatography, the most water-intensive operation in an entire bioprocess (3). Process intensification strategies can address the environmental impact of a process with the goal of producing more product with the same or smaller facility footprint and less capital equipment. A smaller facility offers significant sustainability benefits due to reduced energy consumption (e.g., heating, ventilation, and air conditioning, HVAC). For all the above scenarios, a re-imagination of current chromatography approaches is essential.

Re-Imagining Chromatography Eases Facility Bottlenecks

Increased Productivity with Minimal Process Changes: Process intensification often does not require significant changes to process parameters, workflow, or facility operations; a process can be largely unchanged but have increased productivity. Accumulated process understanding still is valid, and limited optimizations are required. For example, switching from multiuse systems to single-use consumables can increase reproducibility, accelerate timelines, and improve flexibility.

Relieve Supply-Chain Tensions: Improved efficiency offered by process intensification can help limit required consumables, creating a lean process with reduced operational expenditure and limited CoG. One example is to switch from resin to membrane chromatography in rapid cycling mode. Chromatography membranes such as the Sartobind Rapid A membrane improve consumable use, eliminating the task of ordering and storing significant volumes of expensive resins. This is extremely important for a contract development and manufacturing organization (CDMO) that stores different types of resins and columns for multiple customers.

Process Intensification Approaches Are Flexible: It is important to remember that there is no single route to process intensification. The pathway chosen depends on a facility’s constraints, pipeline, strategies, and company goals. More and more options are available to couple upstream intensification with downstream intensification, helping manufacturers re-imagine their chromatography workflow. For example, switching from multiuse batch to single-use multicolumn chromatography with the Resolute BioSMB system binds more product with more efficient resin use, shortening process times and reducing costs. Alternatively, if multiuse technologies are desired, the Resolute BioSC platform enables the performance of four steps on a single system, supporting a productive, continuous process.

Automation: Implementation of process intensification goes hand in hand with automation. A facility with intensified operations can operate with fewer personnel. Integrating process analytical technologies (PATs) can unlock novel, at-line data, contribute to more robust processes, and remediate traditional QC bottlenecks between unit operations (5).

Overcoming the Fear of the Unknown: Making changes to an already satisfactory process or adopting new technologies might be interpreted as inviting unnecessary risk. Often, capital expenditure in a manufacturing suite is already done (chromatography systems have been set up and large columns purchased), and intensification might require additional equipment and training. However, increased competition between technology suppliers has generated diverse solutions to solve downstream process intensification challenges, so it is possible to find a strategy to maximize productivity even with significant facility constraints.

Ultimately, making such changes is critical to remaining competitive and reducing costs, especially with the upcoming cost pressure on drug prices and increased competition from biosimilars. The implementation of downstream process intensification requires a culture change and willingness to re-imagine chromatography operations, whether that involves small steps and modifications to existing processes or building a new, intensified process.

Where Do I Start?

Normally, a stepwise approach is taken to minimize disruptions, digest these innovations, and build a technology experience.

Identify Your Main Bottlenecks: A good starting point is identifying the major constraints in the process and manufacturing suites. If supply chain tension, stock challenges, and high CoGs are major roadblocks, it is advisable to focus more on consumables and single-batch options. Alternatively, if reducing the time to clinic is a key driver, the main opportunities will be to reduce downstream process times, ideally by choosing connected or continuous options. If perfusion systems are in place to adapt to product demand during clinical phases, coupling upstream process steps to the first downstream process steps (clarification and capture) can reduce process timelines significantly.

Take It Step-By-Step: Fortunately, process intensification does not necessitate an “all or nothing” approach. Ideally, manufacturers should consider the short-, mid-, and long-term process improvements they want to make. Some equipment facilitates an incremental implementation of process intensification strategies. For instance, the Resolute BioSC system can be operated in batch or multicolumn mode and offers a large range of flow-path configurations to design a tailored multistep system.

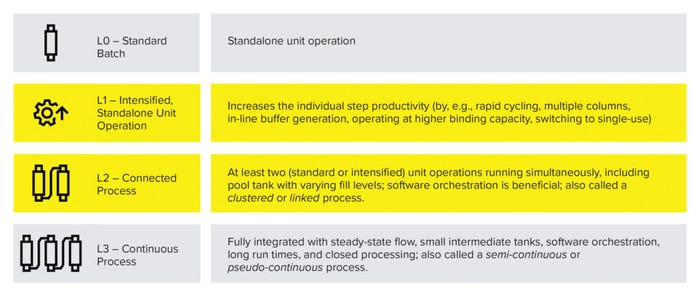

An incremental approach allows you to build the necessary expertise and grow confidence within the operational and quality teams (by carrying out engineering runs, determining the scale-up strategy, performing process validation, and defining the batch). Starting by improving the batch sequence through working with new consumables like novel chromatography membrane formats (such as Sartobind Rapid A in rapid cycling conditions to optimize the use of your consumables) will initiate your journey to the single-batch strategy from early phase trials to commercial production (Figure 1, Level 1).

Figure 1: Sartorius defines levels of process intensification from Level 0 to Level 3 (4).

Consider Single-Use: Process intensification and single-use systems often work harmoniously to create a next-generation facility. Switching from multiuse to single-use technologies might enhance flexibility and accelerate the setup of a new facility, which to some extent can be considered the first step toward process intensification.

Connecting the Parts

The next step is to consider parallel batch and connected process options. One example is to couple an upstream process with clarification, clarification with chromatography (capture), capture with virus-removal steps, or all chromatography steps with ultrafiltration/diafiltration steps (Figure 1, Level 2).

Modular equipment can ease the transition toward faster and more continuous production. The ultimate goal is to have a continuous process from upstream to fill–finish in which biomolecules are not handled during a process, improving safety and quality (Figure 1, Level 3). However, a fully continuous process is not a suitable objective for every product; the end goal is driven primarily by the features of a biomolecule and commercial demands for it.

Embracing New Technologies

There is no universal solution for intensifying downstream bioprocesses. However, many technologies and implementation strategies are adaptable to essentially all process and business needs. The decision about which to use typically is driven by the type of molecules manufactured, their foreseen commercial scale and market demands, and the time a drug is envisioned to reach the market and its potential growth.

Manufacturers should embrace new technologies and innovations in chromatography and engage the help of a trusted partner to overcome fears of change and mitigate risks.

Are you ready to re-imagine your chromatography process? Learn more at https://www.sartorius.com/en/products/process-chromatography.

References

1 United Nations Department of Economic and Social Affairs. Transforming Our World: The 2030 Agenda for Sustainable Development. Department of Economic and Social Affairs, United Nations General Assembly, 2015; https://sdgs.un.org/publications/transforming-our-world-2030-agenda-sustainable-development-17981.

2 Barbaroux M, et. al. Driving Environmental Sustainability in the Biopharmaceutical Industry: A Roundtable Discussion. BioProcess Int. eBook, 2023; https://bioprocessintl.com/sponsored-content/driving-environmental-sustainability-in-the-biopharmaceutical-industry.

3 Budzinski K, et al. Introduction of a Process Mass Intensity Metric for Biologics. New Biotechnol. 49, 2019; 37–42; https://doi.org/10.1016/j.nbt.2018.07.005.

4 Crowley L, Cashen P, et al. Reviewing the Process Intensification Landscape Through the Introduction of a Novel, Multitiered Classification for Downstream Processing. Biotechnol. Bioeng. (submitted) 2023.

5 Rogler K, et al. Enhanced Process and Quality Control for Multi-Column Chromatography Using UPLC Technologies. 2003 Sartorius white paper; https://www.sartorius.com/download/1449286/rapid-monitoring-of-biomolecule-attributes-whitepaper-en-b-p-1–data.pdf.

Katy McLaughlin ([email protected]) is a scientific content writer at Sartorius. Piergiuseppe Nestola is a manager of process technology, and Fabien Rousset is a principal expert in chromatography.

You May Also Like