The RAMbio Incubator Improves Culture Growth and Protein ExpressionThe RAMbio Incubator Improves Culture Growth and Protein Expression

August 1, 2013

End oxygen limitations when growing Escherichia coli, Streptomyces, Pichia, Aspergillus, and other high-demand aerobes in shake flasks. Many bioprocesses rely on aerobic growth and protein expression, yet traditional orbital shakers do not provide adequate oxygen. Cultures become oxygen limited. The RAMbio incubator solves this problem by providing active headspace refreshment using low-frequency acoustic energy that aerates standard shake flasks.

Why Use the RAMbio?

The increased dissolved oxygen provided by the RAMbio may benefit aerobic microbial cultures by

Increasing biomass, protein, or plasmid production

Preventing oxygen limitations from obscuring results

Providing better scale-down models during development

Improving culture conditions without complex equipment

RAMbio vs. Orbital Shakers

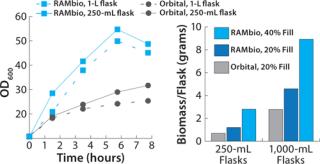

Batch growth and protein production characteristics of E. coli K12 expressing green fluorescent protein (GFP) was evaluated using standard shake flasks in the RAMbio. For comparison, an orbital shaker at 400 rpm with a 0.75-inch orbit was also tested. Cells were grown at 37 °C in rich medium.

RAMbio Improves Growth and Productivity: The RAMbio significantly improved culture productivity and kinetics relative to the orbital shaker. The exponential growth phase was accelerated in the RAMbio flasks, resulting in greater cell densities compared with flasks from the orbital shaker (Figure 1LEFT). Meanwhile, the specific GFP productivity in RAMbio flasks was two- to fourfold greater than those achieved in the orbital shaker (Figure 1RIGHT).

Figure 1: ()

No Oxygen Limitation in the RAMbio: Dissolved oxygen dropped precipitously to anaerobic levels in orbital flasks, whereas the dissolved oxygen in the RAMbio was at least 20% at all times, despite faster growth rates (data available online). These data suggest that the RAMbio provides superior oxygenation at both 20% and 40% fill volumes.

Find more information about the RAMbio online at www.applikonbio.com/ram.

About Applikon Biotechnology

Applikon is a leading provider of equipment for fermentation and cell culture. We understand bioprocess engineering for improved cell growth and performance, and we have applied these fundamentals to bioreactor systems ranging from <1 mL to greater than 3,000 L in size. For over 30 years, our systems have been used for high-throughput screening, process development, pilot evaluation, and production throughout the world.

About the Author

Author Details

Wesley D. Marner II, PhD, is manager of small-scale technologies, 1-608-616-9362; [email protected]; www.applikonbio.com/wmarner.

You May Also Like