- Manufacturing

- Sponsored Content

Case Study: Overcoming the Design Challenges of Expanded Bed Adsorption ColumnsCase Study: Overcoming the Design Challenges of Expanded Bed Adsorption Columns

August 11, 2016

Sponsored by Grifols

Eduard Noguera (managing director, Grifols) BPI Theater @ INTERPHEX, April 27, 2016, 11:20–11:40 am

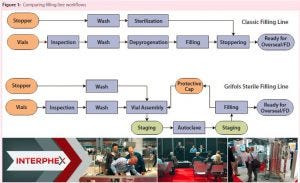

Hematologist Dr. Jose Antonio Grifols pioneered blood banking and transfusions and founded the Grifols company in Spain, 1940. Present-day Grifols specializes in plasma and protein therapies. Grifols Engineering focuses on design and equipment for process engineering. The speaker has worked for this company for about 15 years in process engineering, including fill-finish processes. He described the company’s invention — the Grifols filling method — which prevents particulate and microbial contamination during aseptic filling operations.

During this filling process, all machines are linked together to limit exposure of drug products to the environment. In step one, the first machine inspects glass vials for imperfections, then washes and dries them, assembles the vials and stoppers together, and encases them in protectors to prevent contamination. Step two places them into an autoclave for sterilization. Next, vials go to a class A room, where the protectors are removed. With their stoppers on, vials go on to a filling station, where stoppers come off, vials are filled (product measured by weight), and stoppers are quickly replaced. Finally, the filled vials move to a laser-sealing station, where they are then labeled.

Detailed discussion followed about how the protectors worked and maintained sterile conditions.

Further Reading

May T, Pohlmeyer K. Improving Process Economy with Expanded-Bed Adsorption Technology. BioProcess Int. 9(1) 2011: 32–36.

You May Also Like