Development of a High Capacity, Mixed-Mode Resin for High Conductivity MAb FeedstocksDevelopment of a High Capacity, Mixed-Mode Resin for High Conductivity MAb Feedstocks

August 1, 2012

Cation exchange resins are used in many protein purifications. The high capacity of these resins is very important to process throughput particularly as protein expression levels reach titers >10 g/L. In many cases the feedstock may need to be diluted before loading onto a cation exchange resin to maintain the high protein dynamic binding capacity (DBC) reported by the manufacturer. The additional water, buffer volumes, and process time add cost to the loading step.

Tosoh Bioscience is pleased to announce the new TOYOPEARL® MX-Trp-650M resin, which shows both high DBC and tolerance to feedstocks with conductivities up to 17 mS/cm. The new mixed-mode (MM) resin has also been engineered to have excellent elution kinetics.

The data show that TOYOPEARL MX-Trp-650M resin

tolerates high conductivity feedstocks with minimal dilution required during loading

exhibits mAb DBCs as high as 90–100 g/L

results in improved resolution and peak shape compared with agarose materials

minimizes process pool volumes with both fast binding and fast elution kinetics.

TOYOPEARL MX-Trp-650M is the optimal resin for protein capture steps where the selectivity and protein clearance needed is lower than with affinity resins. This novel resin an excellent choice for intermediate purifications.

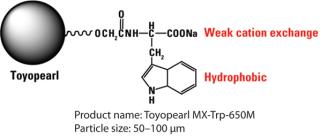

Resin Structure

TOYOPEARL MX-Trp-650M uses tryptophan as the active ligand (Figure 1). This amino acid has both weak carboxyl cation exchange and indole hydrophobic functional groups. The 50–100 µm particle size of this resin is very useful for capture or intermediate purification steps.

Figure 1: ()

Figure 2: ()

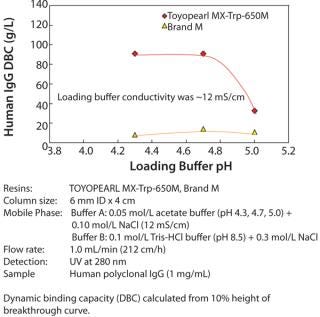

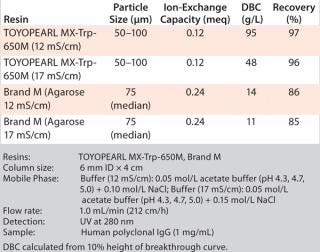

DBC at High Feedstock Conductivities

Table 1 shows the DBC of TOYOPEARL MX-Trp-650M at two feedstock conductivities: 12 mS/cm and 17 mS/cm. For comparison purposes, data for a Brand M agarose resin are also shown. For the 12 mS/cm and 17 mS/cm measurements, the new TOYOPEARL MX-Trp-650M resin shows almost 7× higher and 4× higher DBC, respectively, than Brand M.

Table 1: Dynamic binding capacities (DBC) at high conductivities

Table 1: Dynamic binding capacities (DBC) at high conductivities ()

Mass Transfer Parameters

The mass transfer properties of a resin influence the economics of the loading and elution stages of a capture step, and the degree of resolution for intermediate purification.

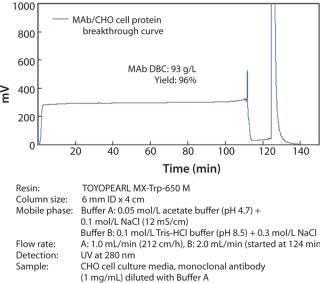

In keeping with the exceptional target binding and eluting properties of Tosoh’s newer TOYOPEARL GigaCap® resins, the new TOYOPEARL MX-Trp-650M also shows a narrow elution peak width to complement its higher capacity (Figure 3).

Figure 3: ()

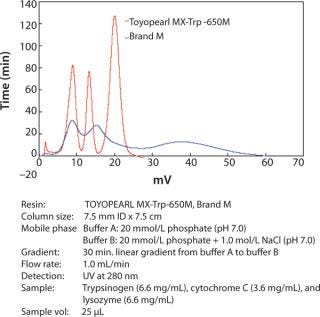

The mass transfer properties also contribute to minimal peak broadening. Figure 4 shows the excellent peak shape for the new TOYOPEARL MX-Trp-650M and the much broader tailing associated with the Brand M agarose material.

Figure 4: ()

Resin Clean in Place (CIP)

The new TOYOPEARL MX-Trp-650M resin has excellent stability to 0.5 mol/L NaOH and can be run for many CIP cycles without decreasing DBC (Figure 5).

Figure 5: ()

Conclusion

TOYOPEARL MX-Trp-650M resin is a high capacity and high performance mixed-mode resin for intermediate purification. The new product has 3–5× the DBC of typical mixed mode resins so reductions in process buffer and pool volumes can be expected. The ability of this novel resin to bind protein from high conductivity feedstock minimizes the amount of water needed for dilution before loading the column.

About the Author

Author Details

Al Jackewitz is the biopurification market manager at Tosoh Bioscience LLC, 3604 Horizon Drive, Suite 100, King of Prussia, PA 19406; 484-805-1219; [email protected]; www.tosohbioscience.com.

You May Also Like