Thermo Scientific HyClone Cell Boost Process SupplementsThermo Scientific HyClone Cell Boost Process Supplements

Major drivers in biopharmaceutical development and manufacturing include improved performance in bioprocess cell culture through increased cell viability, product quality, and yield. Success has been achieved in addressing these drivers using Thermo Scientific HyClone Cell Boost by providing solutions that include strategic supplementation of nutrients based on metabolic profiling of cells and media at various stages of the bioprocessing cell culture campaign. One of the greatest improvements is derived from increased viable cell concentration and volumetric productivity. Today’s experienced fed-batch bioreactor operators can expect more than 10 times the efficiencies possible as compared to a few years ago (1).

Metabolic Pathway Design

High performance with Thermo Scientific HyClone Serum-Free Media for specific cell culture platforms is achieved through our Metabolic Pathway Design technology. Our approach to media formulation development ensures cell productivity during growth and production phases of cell life. This extensive work in media development has resulted in products that provide a consistent nutrient supply in a form acceptable to cultured cells. The Metabolic Pathway Design approach balances nutrient supply against metabolic waste accumulation and determines the effective dose of nutrients critical to the production of recombinant proteins. Media design provides complex lipids and phospholipids that facilitate delivery through the cell membrane. The serum-free media formulations boost yields to levels that are greater than those obtainable using serum-containing media without compromising on performance. Product yields exceeding 20 g/L have been reported, and depending on cloning strategies, 2–3 g/L is now often expected (2).

Thermo Scientific HyClone Process Supplement Platform

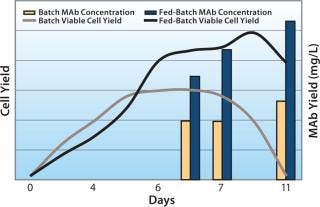

We have developed the Process Supplement platform to support demand in the area of fed-batch cell culture and media customization. These supplements simultaneously address cell viability, product quality, and yield at the same time. Each supplement has been developed through the Metabolic Pathway Design approach to provide specific nutrient combinations such as amino acids, vitamins, lipids, cholesterol, glucose, and/or growth factors in novel combinations for multiple mammalian-cell types in a variety of applications. They have been successfully tested in CHO, PER.C6 (Crucell NV; Figure 1), hybridoma, NS0, HEK 293, and other cell lines.

Figure 1: ()

HyClone Cell Boost supplements are chemically defined and contain no animal-derived components. Each product in the Process Supplements platform has been rigorously tested in a variety of culture systems including shaker flask cultures, traditional stirred tank bioreactor cultures, and disposable cell culture systems (e.g., the Thermo Scientific HyClone Single-Use Bioreactor). Using various serum-free media formulations, the products of the Process Supplements platform have successfully improved cell productivity more than 10 times what had been previously achieved.

About the Author

Author Details

John Manwaring is a scientist, Mark Wight is R&D manager, and Tariq Haq is global senior product manager at Thermo Fisher Scientific, 925 West 1800 South, Logan, Utah 84321; [email protected], www.thermoscientific.com/hyclone. PER.C6 is a registered trademark of Crucell NV.

REFERENCES

1.) Whitford, W. 2006. Fed-Batch Mammalian Cell Culture in Bioproduction. BioProcess Intl. 4:30-44.

2.) Decaria, P., A. Smith, and W. Whitford. 2009. Many Considerations in Selecting Bioproduction Culture Media. BioProcess Intl. 7:44-51.

You May Also Like