Often we are pleasantly surprised at thematic connections that fall within an issue or come between an issue and its supplements — sometimes planned, sometimes a matter of happy coincidence. Setting an issue theme of continuous processing with a featured report on large-scale capacity strategies inevitably created some overlap. At this stage of maturation in its brief history, the biopharmaceutical industry offers myriad choices for facility design, process development, manufacturing paradigms, and partnering arrangements. With many successful examples to choose from, a company can adapt numerous technologies for accelerating processes and reducing final costs to patients.

We could make the increasingly common mistake of thinking of

everything

as falling under the broad term of

intensification

. Editors often take the big-picture approach, finding interrelationships and commonalities and drawing stories from them. The danger comes in muddled thinking and oversimplification — which at the level of corpo...

Although the concept of good manufacturing practice (GMP) was created about half a century ago in the United States, the history of GMP biomanufacturing is relatively short in China, with the first version of GMP rules issued by the Ministry of Health in 1998. In 2010, the ministry issued its fourth version of China’s GMP rules, which came into effect in March of 2011 (1). According to a recent report from BioPlan Associates, the 2010 version raised the standards to be met by biopharmaceutical developers in China significantly, pushing the country to make rapid progress in its overall pharmaceutical manufacturing standards (

1

).

(HTTPS://STOCK.ADOBE.COM)

From Quality by Test to Quality by Design

When China GMP 2010 was issued, the former China Food and Drug Administration (CFDA) — now the State Drug Administration (SDA) — required that sterile production facilities making blood products, vaccines, and so on meet the standards of the new version before 31 December 2013. Existing oral solid-dose preparatio...

The Role of Single-Use Polymeric Solutions in Enabling Cell and Gene Therapy Production - Part 3: Best Practices for Supplier Selection, Qualification, and Validation to Ensure Supply Chain SecurityThe Role of Single-Use Polymeric Solutions in Enabling Cell and Gene Therapy Production - Part 3: Best Practices for Supplier Selection, Qualification, and Validation to Ensure Supply Chain Security

Bio-Process Systems Alliance (BPSA) was formed in 2005 as an industry-led international industry association dedicated to encouraging and accelerating the adoption of single-use manufacturing technologies used in the production of biopharmaceuticals and vaccines. Corporate members include plastic equipment suppliers, service providers, and users in the biopharmaceutical industry who share this mission. A key focus of BPSA’s core activities is to educate its members and others through sharing of information and development of best practice guides that help suppliers, users, and regulators to safeguard the quality of drugs produced with single-use technology (SUT).

Part 3 concludes this article series on cell and gene therapy (CGT) manufacturing. Here, the authors focus on ensuring supply chain security and describe strategies for working with suppliers. The information is based largely on experience gathered from the use of these products in blood processing and biologics manufacturing. Differences between...

Much has been published on improvements and advances in many individual technologies for biomanufacturing. If you take a comprehensive look at the field, however, you find overlap, muddling, and even contradiction about which particular processes or aspects of technological development should be designated properly as

process

intensification

. Although the industry is addressing such distinct goals as improved manufacturing yield, product quality, and cost-effectiveness, the names of initiatives commonly applied to accomplish those goals overlap at best. Such ambiguity and lack of precision can lead to inefficiencies and errors across the industry or even within individual companies (

1

).

Perfusion can improve upstream productivity in a number of ways. When used in seed trains, it can increase temporal and footprint productivity. When used in production, it can increase volumetric productivity. Also shown here is a single-use ReadyToProcess WAVE Cellbag bioreactor from GE Healthcare.

The Cambridge Uni...

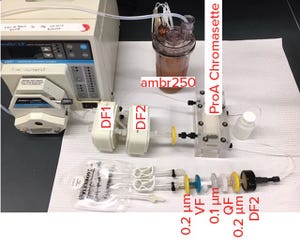

Antibody production platform processes have been widely adopted in biomanufacturing, but many unit operations are not suitable for integration and automation. Here we describe the work of integrating unit operations by transforming a column operation to a more robust cassette format. We have selected a biomolecule-friendly buffer (phosphate) to eliminate, or delay, the performance of a circulating tangential flow ultrafiltration/diafiltration (UF/DF) operation, so the harvest-to-purified-bulk process can be integrated, resulting in a single, direct-flow operation, that reduces the batch process time from about two weeks to six hours.

Figure 1:

Antibody production platform

Antibody production platform processes were established in the late 1990s. In the past 20 years, biomanufacturers have been using engineered Chinese hamster ovary (CHO) and NS0 cells to produce antibodies, bispecific biomolecules, and other fusion proteins. Figure 1 shows the current platform process.

Such processes are associated with ...

Current biomanufacturing is driven to pursue continuous processing for cost reduction and increased productivity, especially for monoclonal antibody (MAb) production and manufacturing. Although many technologies are now available and have been implemented in biodevelopment, implementation for large-scale production is still in its infancy.

RENTSCHLER BIOPHARMA (WWW.RENTSCHLER-BIOPHARMA.COM)

In a lively roundtable discussion at the BPI West conference in Santa Clara, CA (11 March 2019), participants touched on a number of important issues still to be resolved and technologies that are still in need of implementation at large scale. Below, moderator Peter Satzer (senior scientist with the Austrian Center of Industrial Biotechnology, Vienna) summarizes key points raised in that session. Based on his highlights, BPI asked a number of industry representatives to comment on those points further, and their responses follow.

Requirements for Continuous Downstream Applications

by Peter Satzer

Minimizing Buffer and...

Operating a successful global supply chain to deliver single-use systems (SUS) for utilization in the biopharmaceutical industry is complex. In his insightful article, Claudio Catallo, Head of Global Supply Chain Management FMT at Sartorius Stedim Biotech, details the company’s intelligent approach to supply chain management and the models it uses. He also explains how expert teams and integration of digitalization across many sales, manufacturing, and distribution sites maintain the operational excellence required to support supply and demand in an ever-changing global biopharmaceutical market.

Just fill out the form below to download the article now.

References

1

BioPhorum.

Biomanufacturing Technology Roadmap Report

, 2017; https:// www.biophorum.com/wp-content/ uploads/2017/11/Biomanufacturing- Technology-Roadmap.pdf.

2

APICS Dictionary

; http://www.apics. org/apics-for-individuals/publications-andresearch/ apics-dictionary.

Corresponding author

Claudio Catallo

is head of global supply chain m...

Sponsored Content

Critical Considerations for Fill–Finish Manufacturing: Demand to Increase Speed and Flexibility While Maintaining Sterility Spurs Adoption of Novel TechnologiesCritical Considerations for Fill–Finish Manufacturing: Demand to Increase Speed and Flexibility While Maintaining Sterility Spurs Adoption of Novel Technologies

The global market for biopharmaceuticals continues to grow at a rapid pace, with a 9.5% compound annual growth rate (CAGR) predicted over the next eight years. That translates into more than $500 billion in projected growth. So it is no surprise that biopharmaceutical manufacturers are investing heavily in new facilities, technologies, and pipelines for manufacturing drug products.

Even so, the need to prevent contamination places stringent handling and packaging requirements on biomanufacturers. Sterilizing equipment often requires steam autoclaves and dry heat, and even can include treatment by irradiation. In fact, the US Food and Drug Administration (FDA) mandates that all containers used in a sterile manufacturing process must be sterilized before contact with a drug product. The agency has recalled a number of pharmaceutical products for failing to comply with this requirement.

For those reasons, a growing number of biomanufacturers are turning to new aseptic fill–finish technologies, including blow...

byBJ Hull

George S. Weeden, Jr., is a scientist in global manufacturing science and technology (MSAT) process science at Sanofi. We recently chatted about the topic of continuous chromatography.

What are the general reasons for companies to consider continuous chromatography? And what are the caveats?

The main driver for considering continuous chromatography is reducing the cost of goods (CoG). Continuous chromatography improves productivity (mass of product per volume of stationary phase over time) and thus increases throughput or decreases volumes of stationary phase needed. If cost savings are insignificant, then the many additional benefits to continuous processing won’t matter. A secondary driver would be that continuous processes generally provide more consistent product quality and increased process robustness compared with their batch counterparts.

Generally, continuous processes have smaller equipment footprints for more efficient use of plant floor space. Compared with an equivalent batch process, solven...