WWW.LIFETOUCH.COM

The merging of Informa’s KNect365 division with pharmaceutical events operated by UBM brings another opportunity for BPI’s successful “BPI Theater” program: the “BioLIVE” theater taking place at CPhI. Our first foray into the theaters — our own speaker/roundtable sessions held in the exhibit halls of large events — was at a BIO International Convention some years ago. Through our relationship with the Biotechnology Innovation Organization, that came about to bring more technical content into the big event. As BIO grew from modest beginnings, much of its technical content gave way to partnering and business development — arguably the best focus for that organization, but not for core BPI readers. So our goal was to offer technical content to bridge the gap between BIO attendees’ science and business interests, adding a level of technical detail to some discussion that might be more general within the larger conference program.

With BIO already a biotechnology event, our theater was not mu...

The “biopharmaceutical ecosystem” is a multibillion-dollar industry that encompasses large and small drug companies; ancillary providers of services, technologies, equipment, and infrastructure support; and tertiary groups that provide policy direction, regulatory standards, incubator space, and more. This ecosystem is vast and dynamic, evolving constantly as new ideas take hold to push the industry in new directions and present new opportunities for innovation and commercialization.

Figure 1: The biopharmaceutical development pipeline

However, many companies operating within this ecosystem struggle to understand their development and commercialization strategies, and many are developing “me-too” or “follow-on” products that lack differentiation and competitive advantage. On the other hand, some organizations possess breakthrough products or technologies but struggle to make themselves heard and differentiate their offerings among thousands of other vendors and suppliers in the marketplace. Here, I offer ...

WWW.ISTOCKPHOTO.COM

China has long served as “the world’s factory,” but many experts in the biopharmaceutical industry have assumed that making consumer electronics, clothing, and toys for a global consumer base does not translate well to making complex biologics on the global stage. However, according to a newly released report, the biopharmaceutical market in China reached a value over US$9 billion in 2018, with the domestic monoclonal antibody (MAb) market there making up a very large percentage of that (

1

).

Much of those domestic sales are made by the 180 biologics manufacturers currently operating in the country. But our research suggests that this is only the beginning for biologics in China. In fact, biologics account for just 10.4% of sales of all drugs sold there (

1

). So a substantial domestic clinical need remains. But whether and how this growth can be translated effectively into success for China as a player on the global biopharmaceutical stage still is in question.

China has become “the ...

Working with single-use bag assemblies

The increasing uptake of single-use technologies (SUTs) in critical current good manufacturing practice (CGMP) processes and applications has made their integrity a critical quality attribute (CQA) for both suppliers and end users of such systems. Current regulations focus on final packaging, however, without taking into account the unique aspects of assemblies used in bioproduction. Ongoing initiatives include revision of PDA TR 27 (

1

) and creation of A STM workstreams (

2

,

3

) to propose good practices for the integrity of single-use systems. In the absence of a regulatory framework or guideline specifically applicable to such systems used in bioproduction, a risk-management approach is recommended. In addition, scientific understanding of the critical defect size for a risk of liquid leakages and/or microbial contamination is a prerequisite for integrity control strategies to correlate maximum allowable leakage limits (MALLs) with the detection limits of physi...

Figure 1: Analytical method lifecycle

The concept of an analytical lifecycle has been well received in the biopharmaceutical industry. In 2016, the US Pharmacopeia (USP) advocated for lifecycle management of analytical procedures (

1

) and defined its three stages: method design development and understanding, qualification of the method procedure, and procedure performance verification. The US Food and Drug Administration (FDA) has published guidance on process validation with a similar division into three stages: process design, process performance qualification, and process performance verification (

2

). For a manufacturing process, process performance must be monitored. For an analytical method, a method procedure performance must be monitored.

Following the analytical lifecycle concept, an analytical method lifecycle can be divided into five phases (Figure 1). Before you validate a method, you should have an

analytical

target profile

in which you define a method development’s goals and acceptance...

Figure 1: Reactions in the SHP631 I2S activity assay: In the first step catalyzed by I2S, the substrate (IdoA2S-4MU) is hydrolyzed to IdoA-4MU and sulfate. In the second step, 4MU is released by the action of IDUA. Fluorescence quantitation of 4MU product is carried out following a high-pH quench.

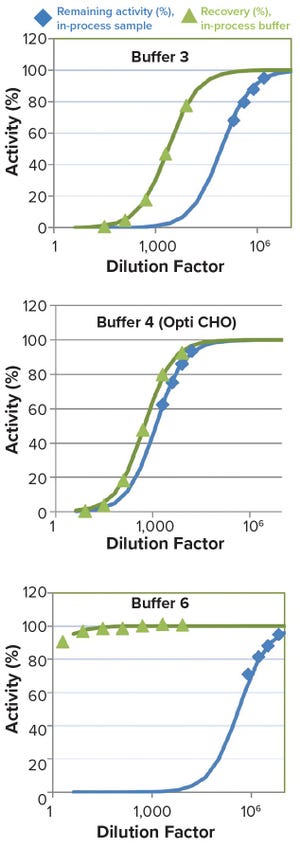

The recombinant fusion protein SHP631 consists of a chimeric monoclonal antibody binding to human insulin receptor and iduronate-2-sulfatase (I2S). This product is being developed as an enzyme replacement therapy to treat cognitive symptoms of Hunter’s syndrome. Because the current therapy (idursulfase, brand name Elaprase from Shire) cannot cross the blood–brain barrier (BBB), SHP631 is being developed to do so, enabling the presence of I2S in the brain. The enzymatic activity of this molecule is measured using the substrate 4-methyl umbelliferyl-α-L-idopyranosiduronic acid 2-sulfate (IdoA2S-4MU). The measured specific activity of SHP631 in-process samples tends to be lower when measured at lower dilution facto...

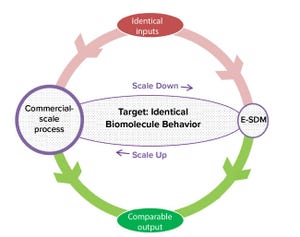

Figure 1: Biopharmaceutical manufacturing process overview

Large and complex protein molecules used as therapeutic agents are manufactured in a series of process steps that start with thawing of cell-bank vials and finish with filling and packaging (Figure 1). The cost and complexity of commercial-scale biomanufacturing processes make them prohibitive to troubleshoot or experiment at full commercial scale. Biopharmaceutical companies routinely use scale-down models (SDMs) of licensed commercial-scale processes to evaluate raw material changes, process improvements, and deviations (

1

) (Figure 2).

Figure 2: Scale-down models reduce time, labor, and costs and enhance ease of use.

Here, we outline some considerations in SDM design, then describe a case study about how an end-to-end representative downstream SDM (E-SDM) was developed and used in a postlicensure process transfer for a biological product.

Table 1: Type of scale-down models (SDMs) and categories

Types of SDMs

Many types of SDMs are used to supp...

How to reduce costs, while still increasing speed, and flexibility in biologics manufacturing currently represent major issues for the biopharma industry. In this article, Burkhard Joksch, Product Manager Bioprocess Automation and Stuart Tindal, Product Manager FlexAct® Platform at Sartorius Stedim Biotech GmbH, detail the evolution of automation for single-use technology towards modular packaging units. They also including case studies of how these units can be used in real life cGMP processes, as well as explain the manufacturing and industry benefits smart modular packaging units can deliver for biomanufacturing both now, and in the future.

Corresponding author

Burkhard Joksch

is Senior Manager Software and Automation, [email protected].

Stuart Tindal

is Product Marketing Manager FlexAct at Sartorius Stedim Biotech, Goettingen, Germany; +49.551.308.0.

Immunotherapy has made incredible strides over the past several years. Studies have shown it to be effective in treating many diseases that attack the immune system, such as multiple sclerosis, rheumatoid arthritis and psoriasis, and (most recently) cancer. With the latter in particular, although immunotherapy is proving to be effective for some patients, most do not respond to the treatment. It is time for the industry to reevaluate how it approaches immunotherapy especially for treatment-resistant patients.

In the fight against cancer, the most powerful tool in the clinic is the human immune system. When a person’s immune system is fully functional, cancer rarely occurs. Even when it does occur and gets treated, a fully functional immune system will fight off the residual disease, thus preventing relapse. However, when the immune system is compromised, as often it is in oncology patients, it is unable to control the cancer as it continues to grow. To beat cancer, a patient’s immune system needs to be re...