October 2016 Supplement

Good things come in small packages — like this issue, for example. Each author brings a critical aspect of regenerative medicine development into perspective, highlighting progress and remaining challenges. I am especially pleased to highlight the current stage of gene therapies.

At cell therapy conferences a few years ago, some people insisted to me that quality by design (QbD) would have little to no relevance for these advanced therapies. Speakers were academic and medical researchers or commercial manufacturers of traditional biopharmaceuticals, but few appeared to be working to connect those perspectives. This issue makes an excellent case for the utility of QbD. As cell/gene therapies progress toward large-scale viability, demonstrating process control and managing risk leads logically to approaches that are establishing themselves in the larger biopharmaceutical industry.

In his introductory article, David Orchard-Webb says QbD can help companies “determine the most influential critical process par...

ADOBE STOCK (HTTP://STOCK.ADOBE.COM)

Regenerative medicine includes both cell and gene therapies. Currently 672 regenerative medicine companies operate around the world, and 20 products have been approved by the US Food and Drug Administration (FDA). Of 631 ongoing clinical trials by the end of 2015 (

1

), over 40% are in oncology, followed in prominence by cardiovascular and infectious diseases. Here I focus on gene and cell therapy bioprocessing in which the final products delivered to patients are cells.

Cell therapies are either autologous (derived from a single patient, for that patient) or allogeneic (coming from a banked donor source, for many patients). The former do not face risks associated with cell rejection; however, they are much more expensive to manufacture and distribute than the latter. Although Dendreon’s Provenge autologous cell therapy was approved by the FDA, it ultimately failed commercially because of its high cost to patients due to a manufacturing and distribution model that was ...

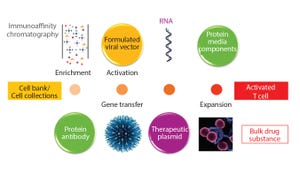

Figure 1: Manufacturing overview for viral vectors and modified T cells; MCB = master cell bank

The concept of gene therapy is far from new, with initial studies performed over 20 years ago (

1

). However, in the past few years an explosion of interest in this area has gone beyond initial regenerative approaches using viral vectors. Interest is now moving increasingly into potential use of T cells modified using recombinant viral vectors for immunotherapy applications. Such therapies are based on using either adenoassociated virus (AAV) or lentivirus (

1

), both vectors being frequently generated through transient expression routes based on plasmid DNA as a starting material.

The viral vectors are generated using two, three, or four plasmid constructs for each vector with two or three structural/helper genes and a single therapeutic transgene. These are then used to generate the viral vector of choice (Figure 1).

Figure 2: Starting material for modified T-cell production

It is widely recognized that manuf...

Figure 1: Affinity chromatography principle: target-specific ligands are chemically immobilized or “coupled” to a solid chromatographic support. The complex mixture that contains the target molecule with impurities is loaded over the affinity column, and the target molecule that has specific binding affinity to the ligands on the resin will bind. Impurities are washed away, and the bound molecule is eluted from the column, resulting in its purification from the original feedstock.

Over the past decade, gene therapy applications and their importance in the biopharmaceutical industry have been increasing. Gene therapies promise versatile treatment options that could revolutionize and transform medicine. As treatment modalities, they offer the possibility of long-term and potentially curative benefits to patients with genetic or acquired diseases. Gene therapies are designed to treat disease by delivering genetic material that encodes a protein with a therapeutic effect into a patient’s cells. It can be used...

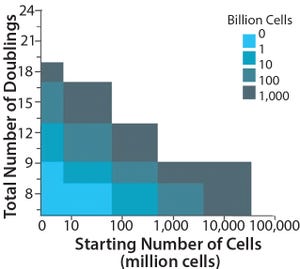

Figure 1: Recommended range of manufacturing lot sizes across different demands. Vertical axis shows examples of different demands. For each level of demand, the horizontal bars show the range of recommended lot sizes. This figure was generated under the assumption that the minimum and maximum numbers of lots that a given facility could produce in a year are 10 and 200, respectively (

5

).

Cell therapies (CTs) offer potential treatments for a wide range of medical conditions (

1

–

6

) by replacing cells, repairing tissues affected by either disease or damage (

7

), or delivering genetic or molecular agents that promote self-healing (

8

). CT research and development is continuously growing (

9

), with increasing numbers of CT candidates reaching phase 3 clinical trials (

9

–

11

). Developers aim to make products that can survive in a competitive landscape while complying with stringent regulatory requirements to control the quality and safety of their therapies (

12

). Successful commercialization require...