- Sponsored Content

Next-Generation Software Solutions for Analytical Chromatography ProcessesNext-Generation Software Solutions for Analytical Chromatography Processes

September 28, 2022

Sponsored by BIA Sartorius

High-performance liquid chromatography (HPLC) has become a leading analytical method for biopharmaceutical process development and optimization, particularly for therapies that leverage plasmid DNA (pDNA), messenger RNA (mRNA), and viral vectors. In July 2022, Blaž Goričar (manager of process analytics development at BIA Separations, a Sartorius company) demonstrated the features of his company’s PATfix software for HPLC data processing and analytics. He described how the program can simplify method execution and enhance evaluation of resulting data.

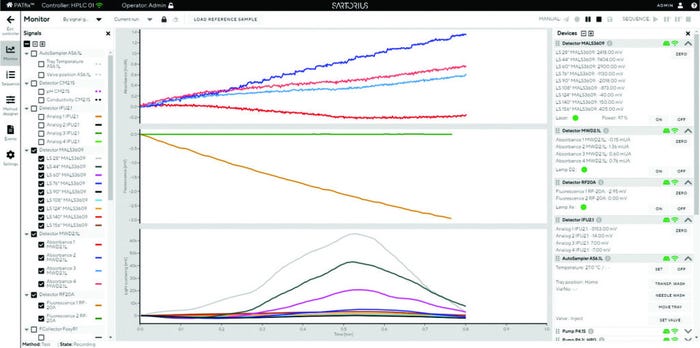

Photo 1: PATfix software from BIA Separations, a Sartorius company.

Goričar’s Presentation

PATfix software is a client–server application for simple, secure access to HPLC data. A small personal computer is used as controller to transmit process data automatically from connected chromatography equipment (e.g., pumps, detectors, and autosamplers) to a server for processing, storage, and analysis. Desktops, laptops, and other clients can access collected data by logging into the application website. Calculations are performed on the server, freeing up computing power on the client side. The software is compatible with Windows, Apple, and Linux operating systems.

Upon login, users can select from several menus. The “platforms” menu houses instructions for different HPLC operations — e.g., monitoring of in vitro mRNA transcription. Menus for “samples” and “sequences” provide unified, searchable databases for easy application of process materials and parameters. In the “projects” menu, administrators can add tasks, delegate activities to team members, and assign permissions for data reading and writing. That feature, along with a complete audit log, ensures 21 CFR Part 11 compliance. Tools in the “analyses” menu provide different ways to visualize data from selected samples. For instance, PATfix software enables manual and automatic peak integration. Analyses can be exported in multiple file formats.

Goričar focused on tools for designing and executing experiments in the “controller” menu. Users can take control of a chromatography module remotely, load a new or established method, adjust relevant parameters, and perform the designed run. Data are processed in real time because PATfix software connects to multiple sensors that integrate with pumps, detectors, valves, and other components of PATfix HPLC chromatography modules. The software also can connect with a “triple-detector” product that comprises a nine-channel multiangle light scattering (MALS) sensor, a two-channel fluorescence probe, and a four-channel multiple wavelength detector (MWD).

From the same menu, users can monitor and modify process inputs and parameters. Goričar showed how to specify and observe a change in buffer composition. Adjustments can be made to several pumps, detectors, valves, and other module components.

The primary goal of the PATfix software suite is to provide users with a powerful yet easy-to-use tool for advanced data evaluation. Thus, the software leverages an intuitive interface and establishes a single point for collection, access, and analysis of information from multiple HPLC systems. PATfix users also can benefit from a feature that enables interactive presentations of chromatographic data, facilitating collaboration across colleagues, functional groups, and even external companies that have been given requisite permissions.

Questions and Answers

Do users access PATfix software through an internal or external server? The application is hosted on a server inside of a user company’s intranet. It can be accessed securely by internally connected devices and external clients provisioned with virtual private networks.

Can peak names be added automatically for all injections in a run? Users can leverage software-provided mathematical templates or create new ones. Those can be applied to all selected samples automatically. The same functions are available for activities such as peak integration.

Find the full webinar online at www.bioprocessintl.com/category/webinars.

You May Also Like