- Sponsored Content

Novel Single-Use Sensors for Biopharmaceutical ApplicationsNovel Single-Use Sensors for Biopharmaceutical Applications

August 15, 2014

The increasing adoption of single-use technology in biopharmaceutical, vaccine, and cell therapy production is one indication that such technology has moved far beyond its novelty stage. Arguably, this is the preferred technology of newly developed processes. To support the continued growth of single-use systems in the biopharmaceutical industry, the ability to measure critical process parameters with single-use sensors is required. Several key single-use sensing technologies are described, including pressure, temperature, UV absorbance, and conductivity. The technology behind each is explored as well as examples of the sensors in practical applications.

Pressure Sensors: Single-use sensors for pressure measurement have already become widely accepted and adopted. This is partly attributed to the fact that pressure is the most critical measurement related to process performance (as well as safety) for many different bioprocesses. Products such as PendoTECH single-use pressure sensors are used to measure pressure on filtration, chromatography, and disposable bioreactor processes. They are available in a wide range of sizes and different connectors to readily adapt to process components (see photo).

The core technology is based on a MEMs chip (micron-sized devices formed by combining mechanical parts and electronic circuits, typically on a semiconductor chip). On these mass-produced chips, a microdiaphragm measures pressure. The chip includes temperature-compensation elements that adjust the chip’s electrical output signal based on fluid temperature. PendoTECH MEMS-HAP chips are made to very tight manufacturing tolerances, and those that pass those specifications are made into completed pressure sensors by assembly with the plastic fitting and other elements. So the critical pressure-measurement element is manufactured separate from associated expensive, precision electronic instrument components that read the sensor.

PendoTECH’s PressureMAT instrument contains the precision electronics. It supplies a precise voltage to the MEMs chip, reads the resulting millivolt signal, and converts the signal to a pressure value. PendoTECH also offers a signal conditioning card that reads a single sensor up to 30 psi and supplies a corresponding mA signal for a control system.

Temperature Sensors: Temperature is most frequently measured with an RTD, thermocouple, or thermistor. Thermistors are mixed metal oxides that can be mass-produced at low cost. Although its disadvantage compared with an RTD is that it has a narrower temperature range (with suitable sensitivity of 070 C 0.1 C ), a thermistor’s range suits most disposable bioprocess applications. PendoTECH single-use temperature sensors are one type of product. The thermistor is made to the specification of a 2,252-ohm at 25 °C and a distinct resistance-versus-temperature curve. The thermistor can be affixed to a unit operation through a tube that is mounted to a class VI plastic in-line fitting, which yields an accurate measurement of fluid temperature. Its measurement can be read and coverted to temperature by a number of different devices.

UV Sensors: Measuring ultraviolet (UV) light absorbance involves the commonly known Beer’s Law, which states that the optical absorbance of a chromophore in a transparent solvent varies linearly with both the sample cell pathlength and the chromophore concentration.

Absorbance is measured in a spectrophotometer by passing a collimated beam of light with wavelength lambda through material that is normal to the beam. Absorbance is calculated from the ratio of light energy passing through the sample to the energy that is incident on the sample. The molar absorptivity or extinction coefficient of a chromophore at wavelength lambda is a property of the material as well as the solvent.

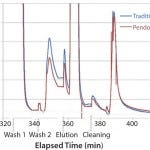

PendoTECH’s flow cell is a single use, in-line sensor with a 1-cm path length. As such, the sensor is separable from the spectrophotometer by using fiber-optic cables that transmit the UV light. PendoTECH’s disposable flow cell has two compartments perpendicular to the fluid path. At the base of each compartment at the fluid path wall is quartz glass. Fiber optics from a compact UV 280-nm photometer are inserted into those compartments to measure absorption. The photometer has a tare button to set the blank, and a 420 mA output that can be integrated to a number of devices for display, data acquisition, and control. Figure 1 shows a real-time direct comparison between the PendoTECH single-use in-line UV sensor against a traditional UV probe. Excellent agreement between the instruments is evident under two different sets of conditions.

FIGURE 1: Comparison between the PendoTECH single-use in-line UV sensor against a traditional UV probe

Conductivity Sensors: Conductivity is the ability of a material to conduct electric current. The principle by which instruments measure conductivity is simple: Two plates are placed in a sample, then a potential is applied across the plates (normally a sine-wave voltage), and the current is measured. Because cell geometry affects conductivity values, standardized measurements are expressed in specific conductivity units (S or mS/cm) to compensate for variations in electrode dimensions.

Because the charge on dissolved ions facilitates conductivity and the dissolution of ionic materials is temperature dependent, conductivity measurements are thus temperature dependent. A useful approximation of the effect of temperature on conductivity is a 2% change in conductivity per 1 °C. Conductivity measurements are usually referenced to 25 °C for consistency purposes. Thus careful and accurate measurement of temperature along with conductivity is critical for the best results. PendoTECH’s single-use conductivity sensors incorporate a thermistor accurate to 0.1 °C directly in the flow path in close proximity to the conductivity electrodes for optimum temperature measurement and subsequent correction to 25 °C. All conductivity meters have either fixed or adjustable automatic temperature compensation referenced to a standard temperature (usually 25 °C). But a meter with adjustable temperature compensation provides an ideal match for a solution being measured. PendoTECH’s two-channel conductivity monitor has the capability to read two conductivity and two temperature measurements.

References

1. Rios M. Flexible Manufacturing: Evolving Technologies Combine to Enable a New Generation of Processes and Products BioProcess Int. 2010 8(5): 34-46

2. Storm, E. Single-Use System Design Engineering Perspective on Selection of Commercially Available Single-Use Instrumentation IBC’s 7th International Single Use Applications for Biopharmaceutical Manufacturing, La Jolla, CA, 14-15 June 2010, IBC Life Sciences www.the-infoshop.com/conference/singleuse10/agenda.shtml

3. Furey J, Clark K, Card C. Adoption of Single-Use Sensors for Bioprocess Operations BioProcess Int. May 2011, Supplement.

Dennis C. Annarelli, PhD, PendoTECH, Princeton NJ; 1-609-799-2299; www.pendotech.com

You May Also Like