Banking Parental Cells According to CGMP GuidelinesBanking Parental Cells According to CGMP Guidelines

It is often difficult to accurately anticipate quality standards across today’s global regulatory environments. In recent years, quality expectations have increased as a result of public demand and government regulation while regulatory requirements are often written with limited specificity. Regulations pertaining to parental cell lines (cells engineered to become biotherapeutic production cell lines) is one such area where current regulations leave room for interpretation. Here we explore some important considerations for determining quality standards for parental cell lines.

Cell Line Development

The science of cell line development is a complex balance of investments in platforms, technologies, and personnel to meet the increasing production demands within shortened development timelines. From expression enhancers to high-throughput screening techniques, the laboratory challenges of cell line optimization continue to grow. They now include the need for improving gene delivery and transfection efficiencies, cell productivities, media conditions, cell line stability, and final product quality. Furthermore, companies must incorporate access to intellectual property, technology coordination, and data and information management into an overall program of cell line optimization to satisfy growing requirements for new product development.

The world market for biotherapeutics is estimated at $80 billion per annum (1), and the number of vaccines produced using biotechnological procedures is growing continuously. Driven by production demands and unmet market needs, scientists have successfully engineered stable cell lines to produce increased yields for a range of biotherapeutics including recombinant proteins and monoclonal antibodies. With the development of new cell lines, these scientists are now challenged to satisfy quality standards for ensuring reproducible and safe cell substrates because the final product quality of biotherapeutics greatly depends on the quality of the cell lines used for their production. This trend to streamline workflows between research and manufacturing has strongly affected the type and scope of cell substrates for in-depth study by biopharmaceutical research teams.

On top of considerations for improving titer and product quality come the dual pressures of speed-to-market and cost reduction. How rapidly and cost-effectively can a concept be turned into a robust cell line? Depending on project complexity, the average time required to generate a stable cell line is six to nine months. As for reducing cost, companies increasingly demand freedom to generate lines exclusive of royalties or licensing fees.

Carefully selecting cell lines that are well-characterized and compatible with production requirements can save a significant amount of development time. As a result, cell line optimization has become a critical but routine step for generating robust and highly productive cells. From drug discovery and cell-based assays to large-scale cell culture for manufacturing, success depends on identifying the right cells that best express the traits you want. Additionally, developing efficient and cost-effective parental cell lines with associated CGMP documentation could play an important role in reducing the downstream risk of adventitious agent contamination, thus streamlining a regulatory package and speeding commercialization of your novel biotherapeutics.

Choosing the Right Cells

Characterizing and testing banked cell substrates are critical to controlling the production of biological products derived from human and animal cell lines. The objective is to confirm the identity, purity, and suitability of cells for manufacturing. Quality concerns for biological products derived from cell lines arise from the possible presence of cellular and adventitious contaminants. Cell banking assures that you have an adequate supply of equivalent, well-characterized cells for production over the expected lifetime of a biotherapeutic product. In addition, cell banking provides the opportunity to undertake a comprehensive characterization of a cell substrate and minimize the likelihood of adventitious agent contamination.

An important part of qualifying a cell line is choosing appropriate testing for the presence of adventitious contaminants. Homogeneity and reproducibility are fundamental requirements of cell banks, so their qualification includes tests for cell identity as well as endogenous and adventitious microbial contaminants (bacteria, fungi, mycoplasma, and viruses). For cells that produce recombinant DNA–based products, analysis of their expression constructs at the nucleic acid level (genetic stability) is also a primary concern. Base your strategy for designing a banked cell safety testing program on sound scientific principles and current regulatory guidance.

After generating cell banks, the most extensive efforts are spent on their quality control. The principles of cell banking and associated safety testing and quality control are addressed by regulatory guidelines for the manufacture of products from animal cell substrates (2,3,4,5).

Regulations for Cell Line Development

To help ensure maximum safety of biopharmaceuticals, several guidelines define international standards. Cell culture processes used in the preparation of biotherapeutics are subject to stringent requirements from official national and international regulatory bodies including the FDA, EMEA, World Health Organization (WHO), and International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH). The practice of documenting procedures, cultures, and reagents used is important for promoting high-quality scientific work and was established to apply to cell substrates used in biotherapeutics manufacturing. Such documentation also provides traceability. Not only do you need to document the qualification of cell banks, it is also important to establish the stability of critical culture characteristics upon passage to ensure reliable performance of cells derived from the cell banks.

Special Considerations for Continuous Cell Lines

Regulatory standards for characterization of master and working cell banks prepared from engineered cells that express a desired biotherapeutic product are provided in the following documents:

Regarding quality standards for parental cell lines, section 2.1.3 of ICH Q5D makes the following suggestion:

A crucial step is the choice of a suitable parental cell line. For recombinant products, a parental cell line is typically the untransfected recipient cell line. The use of characterized parental cell banks is suggested, but is not considered essential. A characterized parental cell bank may be of benefit, especially when multiple cell substrates are generated from the same parental cell type, by providing a set of information on which the quality assessment of the Master Cell Bank (MCB) can be based. (5)

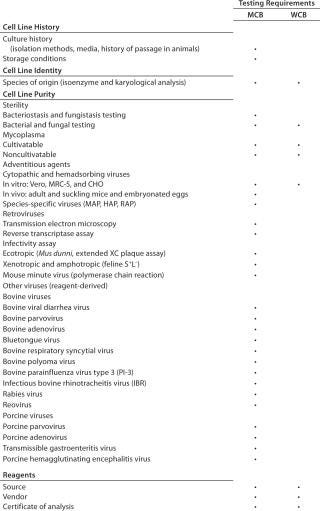

Although parental cell lines are not the main focus of that guidance, the regulation suggests that some supporting documentation is necessary to adequately describe the history of the cell line. The level of detail required to satisfy a regulatory agency regarding the development of a parental cell line remains a matter of interpretation. In general, the lineage of a parental cell line should include a description of the cell source, the results of tests for pathogenic agents, the cultivation history of the cells, and a history of any genetic manipulation or selection of the cell line. Table 1 lists studies recommended to fully document a parental cell line.

Table 1: Example of master cell bank (MCB) and working cell bank (WCB) characterization according to FDA and EMEA, testing requirements

Table 1: Example of master cell bank (MCB) and working cell bank (WCB) characterization according to FDA and EMEA, testing requirements ()

Considerations for Parental Cell Banks

Current good manufacturing practice (CGMP) refers to regulations that require manufacturers of drugs, medical devices, blood products, and some foods to take proactive steps to ensure that their products are safe, pure, and effective. The word “current” is there to remind manufacturers that they must use up-to-date technologies and systems to comply with these regulations. Systems and equipment that 20 years ago were “state of the art” for preventing contamination and errors may be less than adequate by today’s standards.

Regulatory environments are ever-changing; standards are subject to continual revision and vary by country. Commercially available cells are increasingly accompanied by documentation aligned with CGMP requirements for production cell lines, and documentation requirements for parental cell lines may become more stringent. Creating parental cell banks under GMP guidelines requires a significant time investment. You must establish a reliable source of cells and document their history, test results, storage conditions, and chain of custody.

When you obtain CGMP-produced parental cells from an outside source, the ability to incorporate accompanying documentation into your company’s specific regulatory submission paperwork is a distinct advantage.

Producing Parental Cell Banks

Creation from Research Laboratory Stocks: All too often, lineage documentation of parental cell lines that originate in traditional research and development laboratories is either limited or nonexistent. Because of that lack of documentation, manufacturers using such cell lines have been required to essentially “restart the clock” on the cell line’s history. In extreme cases, they may need to select a new clone or adapt their cell line to a new growth medium along with other associated characterization studies. Such activities can be expensive and time consuming, but regulations are clear about the requirement to establish a “clean bill of health” for each parental cell line.

Commercial Parental Cell Lines: Most cell lines available today require costly licenses. These can provide a viable option for some users. Even though licensing costs are often greater than the cost of creating cell banks from research laboratory material, the use of commercially available lines can significantly shorten timelines for developing production cell lines, which may make them more cost-effective.

Parental Cell Lines with Reduced Licensing Burden: One major hurdle in isolating stable, inducible, or constitutive high-level production cell lines is the time-consuming selection process. Given the variation in expression levels of the same construct in individual clones, you may often have to isolate and test hundreds of clones to identify one or more with the characteristics you want. That has led some cell line producers to begin offering cell line development kits. Such kits provide not only CGMP parental cells, but also the components and protocols needed to engineer and select producing clones in a completely serum-free system.

These kits enable biotherapeutics developers to create stable cell lines that express proteins of therapeutic interest. The integrated kit can help reduce the time for development and streamline regulatory documentation — in turn speeding up time to market. For example, Invitrogen offers the GIBCO OptiCHO protein express kit, a Chinese Hamster Ovary (CHO) cell line development kit that includes parental DG44 cells banked under CGMP guidelines and tested to FDA and EMEA requirements. Other examples of cell kits for in house development are those sold for CHO-K1 by Lonza and PER.C6 by Crucell.

With most commercially sold parental cell lines, licensing involves fees for research use in addition to commercial milestones and royalty payments. The level of fees and payments can vary greatly from vendor to vendor based on he level of imbedded technology within the kits and the supplier’s business model. Regardless of the differences in fee structures, the level of documentation for the parental line should be consistent with industry best practices to assure quality of the cell substrate.

A Potential Solution

As regulatory requirements for biotherapeutics become more stringent, increased reporting standards can be expected from different regulatory agencies throughout the world. Documentation requirements may become more critical for parental cells. Companies must consider licensing and royalty burdens in the total cost of a given parental cell line development option.

Cell line development kits could provide an attractive solution for cash-strapped biotech start-ups and pharmaceutical companies. In addition to cost savings (on licenses, royalties, documentation, and regulatory activities), a kit could also reduce productivity problems and downstream difficulties. This type of platform can provide efficient and cost-effective, stable cell line development with associated CGMP documentation. That in turn could lead to streamlined regulatory filings and thus more rapid commercialization of novel biotherapeutics.

REFERENCES

1.) Langer, ES. 2009.Sixth Annual Report and Survey of Biopharmaceutical Manufacturing Capacity and Production, BioPharm Associates, London.

3.) CBER 1993. Points to Consider in the Characterization of Cell Lines Used to Produce Biologicals, US FDA, Rockville.

4.) CBER/CDER/ICH 2001. Guidance for Industry: Q7A Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients, US FDA, Rockville.

5.) ICH Guidance on Quality of Biotechnological/Biological Products: Derivation and Characterization of Cell Substrates Used for Production of Biotechnological/Biological Products; Availability. Fed. Reg. www.fda.gov/downloads/RegulatoryInformation/Guidances/UCM129103.pdf. 63:50244-50249.

You May Also Like