Single-Use Systems As Principal Components in BioproductionSingle-Use Systems As Principal Components in Bioproduction

December 1, 2010

Single-use systems (SUS) have become an accepted component of animal-cell–based bioproduction. No longer a merely exciting possibility, they have emerged as a significant and growing resource for companies to use from process development to manufacturing of approved products. Having been examined for years in less regulated environments, off-the-shelf SUS are now in regular use to some extent in nearly every segment of the production train by contract manufacturing organizations (CMOs) and biopharmaceutical companies in mid-scale production applications. For many operations, in fact, the question has evolved from, Is there an SUS available that can support my process? to, Which system best supports my needs?

Drivers of this rapid acceptance and widespread use in such a conservative industry have been well reviewed in recent years as early adopters experimented with emerging technologies and products (1). In general, advantages are found in capital investment, cost of goods, safety, production scheduling, surge capacity, and process replication.

PRODUCT FOCUS: ALL BIOLOGICS

PROCESS FOCUS: UPSTREAM PRODUCTION AND DOWNSTREAM PROCESSING

WHO SHOULD READ: PROCESS DEVELOPMENT, MANUFACTURING, FACILITY DESIGN/ENGINEERING, OPERATIONS

KEYWORDS: BIOREACTORS, DISPOSABLES, PROCESS MODELING, SUSTAINABILITY, QBD, FLEXIBILITY, SEPARATION, PURIFICATION

LEVEL: BASIC

But this acceptance may not be more generally recognized. Hybrid or integrated implementation is common, with disposable elements operating in line or in concert with reusable materials. Also, bioproduction incorporates many divergent products and production processes, each with its own requirements. Although SUS are now fully accepted for some operations, their potential in others remains to be demonstrated.

Single-use technologies are in a state of remarkable growth, which determines a range of implementation maturity — from systems clearly established by industry leaders to emerging systems being introduced by equipment vendors and academic institutions. Even though such exciting innovations as entirely disposable operations and even closed and modular process trains are possible if yet to be fully realized, the ubiquitous existence and acceptance of an array of disposable components has been firmly established (2,3,4). Reviewed here are some previous concerns regarding SUS implementation that have been clarified recently (Table 1).

Table 1: Most initial challenges for SUS have been resolved by many available systems.

Table 1: Most initial challenges for SUS have been resolved by many available systems. ()

Table 3: Many demands on single-use systems (SUS) have been met, but many remain for certain unit operations and available systems.

Table 3: Many demands on single-use systems (SUS) have been met, but many remain for certain unit operations and available systems. ()

Cost and Finance Advantages

Although accurate comprehensive models of SUS implementation have turned out to be more complex than originally envisioned, solutions or clear paths forward are now available. To begin with, biopharmaceutical manufacturing costs and their modeling per se are not very perspicuous (5). Nevertheless, the consequences of SUS implementation to facility and operational costs — as well as financial strategies — have been determined for many applications and implementations (6). In fact, a growing number of models and case studies are publicly available and supplied for the most part by independent consultants.

Although the list of general features and advantages provided by disposables is long and growing (see “Demonstrated Advantages” box), the cost and financial implications of a particular system often remains case specific. Project- or facility-specific factors include such considerations as what conventional manufacturing equipment is currently in place; the desired type and timing of expenditures; and the value of capacity expansion, facility replication, or rapid product changeover ease (7).

Component Offerings

Introduced over 30 years ago, the first disposable products used in bioproduction included T-flasks, pipettes, and tubings. Since that time, the number and sophistication of SUS has steadily grown. They can now replace stainless steel in entire manufacturing operations. Disposable processing solutions range from such simple equipment as transport containers to completely closed unit operations.

Some advanced systems have been accepted into even the stringent field of biopharmaceutical manufacturing (8). These include process fluid mixing and storage systems, bioreactors, bulk material and product storage and cryopreseveration systems, distribution assemblies and manifolds, sensors, connectors, and a number of disposable filtration and chromatography systems (9). Their “acceptance” by the industry is evidenced by the number of companies successfully using them, their involvement in the manufacture of FDA-approved products, the number of suppliers providing alternative sourcing, and published engineering data (10).

A number of SUS for formulation and holding of media and buffers have been available for some time, supporting 25-L to 2,000-L working volumes (Photo 1). The first mid-scale disposable bioreactors used wave-action agitation, but shortly thereafter, stirred-tank reactors based on marine impellors appeared, paralleling traditional production reactors (Photo 2). Remarkably, more than a dozen styles of disposable bioreactors with capacities of ≥100 L are now available (11), offering process developers a choice of supply and performance features. The number of options is even greater if lesser known, more specialized systems are included (12).

Photo 1:

Photo 1: ()

Photo 2:

Photo 2: ()

For years, single-use technologies (with a few notable exceptions) have had a more restricted range of application in downstream operations. But many exciting recovery-through-finish systems are appearing based on single- and limited-use technology. One difference in the implementation of disposable technology in downstream (rather than upstream) processes is that purification requirements often determine more stringent specifications for material robustness and leachables. Also, surface binding characteristics and particulate burden must be considered. Due to the proximity of downstream disposable elements to final products, risk-analysis may indicate a heightened requirement for testing-based validation and documentation. SUS are now gaining acceptance for large-scale purification, including scalable tangential-flow and depth filtration units (Figure 1).

Figure 1: ()

A surprising number of new, single-use, large-scale purification and polishing technologies are now appearing and at varying degrees of acceptance. The industry’s early adopters are regularly using prepacked, prequalified, and presanitized large-scale chromatography columns designed for limited- or single-use containing many popular resins (13). Scalable single- or limited-use membrane ion-exchange chromatography is now offered in both strong anion- and cation-exchange forms. Membrane adsorbers have been successfully applied to purify DNA, protein, viruses, and other high–molecular-weight products and for DNA and endotoxin removal in polishing steps.

One of the more powerful technologies now making an appearance involves simulated moving bed (SMB) chromatography. For example, the BioSMB system from Tarpon Biosystems (www.tarponbiosystems.com) comprises a series of continuous, disposable flow paths converting a batch chromatographic process into smaller multiple–separation-device processes. It even allows for maintenance of chromatographic resins and buffer systems already familiar to users (14).

Single-use technologies and products are also changing drug-product–based operations (15). Fill–finish operations requiring no laminar-flow controlled environments are now facilitated by closed-system and single-use bags, transfer manifolds, and connectors. Automated, aseptic filling of injectable drugs using SUS is supported by high-speed equipment that can accept ready-to-fill containers.

Materials Acceptability

Despite related concerns in biopharmaceutical production, disposable (plastic) materials in flasks, tubings, and filter membranes have been a part of biomanufacturing trains since the industry’s inception. But introduction of such large-scale systems as mixers, bioreactors, and separation/purification assemblies has required examination of new resins and castings, an expanded range of process conditions, and proximity to active pharmaceutical ingredients (APIs) and dosage forms. Even materials previously characterized and approved (e.g., USP Class VI or ISO 10933-1 compliant) for small-scale use need risk assessments of the greatly increased ratio of single-use surface to process fluid or product mass.

Individual system adopters, government agencies, and nongovernmental organizations have worked to establish clear and practical paths forward. For example, the Bio-Process Systems Alliance (BPSA, www.bpsalliance.org) has developed disposables “best practices” and technical guides on such topics as extractables and leachables testing (16). The International Society for Professional Engineering (ISPE) has established a Product Quality Lifecycle Implementation (PQLI) biotechnology task team to examine these materials issues from a QbD perspective (17). Topics currently in focus include establishing consensus among countries and standards-setting organizations: e.g., the US Food and Drug Administration (FDA), European Medicines Agency (EMA), International Standards Organisation (ISO), American Society of Mechanical Engineers (ASME), and pharmacopoeia.

DEMONSTRATED ADVANTAGES OF SUS OVER CLASSICAL SYSTEMS

Financial Advantages

Reduced Capital Investment: Reduces service requirements, production process and classified area footprint; reduces facility design, install, and qualification activities; converts some up-front fixed costs to variable long-term; supports inexpensive establishment of efficient surge capacity

Reduced COG: Lowers utility costs; requires fewer manufacturing steps and labor requirements; reduces quality activities and preventative maintenance costs; lowers process flow and equipment modification costs; supports rapid and economical process replication and decentralization of production; provides cost distribution advantages

Speed and Efficiency Advantages

Installation Ease: Reduces plant development and start-up time and supports “hybrid” system installations and alterations

Operational Ease: Reduces process steps and validation steps and activity; eliminates cleaning operation costs and downtime; increases plant capacity and production scheduling flexibility, supports aggressive scheduling and campaigning; facilitates flexible approaches in process flow and layout; simplifies and accelerates product changeover and turnaround; supports an evolving “plug-and-play” approach to operational modules and enumerable hybrid reconfigurations; eases CGMP cold-chain logistics and good storage practices, with integral cryopreservation

Change Ease: Supports process modularity and flexibility; increases ease in reconfiguring and extending a production facility, with economical and rapid site-to-site operations transfer; provides for general equipment and process facility independence; supports economical system upgrades and advanc

ements

Environmental and Safety Advantages

Sustainability: Reduces waste, effluent, and use of harmful cleaning materials; lowers water and power consumption, fouled water release; reduces carbon footprint

Safety: Reduces the number of activities open to contamination; offers a growing number of entirely closed operations; lessens operator exposure, lot and product cross-contamination risk; improves compliance values (reduces error potential); eases material transfer between diverse biosafety or classification levels; increases sterility assurance (irradiation rather than steam)

Other Advantages

Manufacturing-Scale Performance: Provides demonstrated scalability within available system sizes; supports existing process sensing, monitoring, modeling, and control

Growing Technology: Increasing numbers and capabilities of novel systems (e.g., connectivity, sensing, chromatography); promise of further improvements (processes and models in infancy, yet to reflect true potential); promise of an expanding range of “closed-system processing” across unit operations

Growth in Acceptance/Validation: Provides for expanding applications up- and downstream

Scale-Up, Technical Transfer

SUS that present consistent configuration and materials through a range of scales ease transfer from small-scale (development) to large-scale (manufacturing) operations (Figure 1). For some time, it has been possible to perform upstream process development in submilliliter-scale SUS microbioreactors. Recently it became possible to move from process optimization in a 3-L stirred-tank disposable bioreactor to production in a 2,000-L stirred-tank disposable reactor while maintaining the very same dissolved oxygen and pH probes, porting, and automated control systems compliant with 21 CFR 11 (e.g., Delta V SIS). Published case studies report the remarkably robust scalability of SUS from micro- to production-scale reactors (18,19)

Supported Products and Platforms

The utility of many disposable processing solutions has been demonstrated at production scales using most standard upstream and downstream platforms.

Upstream this includes fed-batch and some perfusion cell culture modes for all major production animal cell lines, from suspension Chinese hamster ovary (CHO) cells to adherent VERO cells to Sf9 insect cells with the baculovirus expression system (BVES). Processes have been established in single-use bioreactors for different growth rates and cell masses, including attached cultures using microcarriers. Success has been reported even with some microbes that have low growth rates or that generate low cell mass. The utility of single-use bioreactors has been demonstrated in production of proteins, viruses, nucleic acids, cell-based products, and vaccines (14).

Downstream operations are supported for many products. These involve the full range of applications from depth filtration and centrifugation to purification and polishing. For some particular processes, such as protein A chromatography of monoclonal antibodies (MAbs), the current single- or limited-use technologies and commercially available products can be uneconomical.

Regulatory Compliance

Steps toward meeting regulatory requirements for SUS have been encumbered by a paucity of standards, guidances, and best practices specific to bioprocessing disposables. For the most part, compliance has been established with an eye to standards established for traditional systems. However, not only have a number processes involving SUS been validated in biopharmaceutical applications, but comprehensive validation guides and application-specific services are now provided by vendors to aid in efficient implementation of their products. Some are establishing the quality attributes of particular systems, providing the testing required for their qualification, and determining how the contents of regulatory filings might be orchestrated when SUS are involved. Furthermore, the FDA is reported to be very supportive in establishing such processes in the biopharmaceutical industry (20).

Probes, Sensors, and Sampling

First-generation monitoring approaches in SUS operations relied on the creative connectivity of classical probes to disposable equipment. Solutions involving existing aseptic quick-connects have both supported the new systems and provided a continuity in the transition to disposables. However, they have suffered from limited capability at smaller scales. Manufacturers are now working to establish a second generation of sensors, incorporating a number of novel and powerful technologies (21).

A growing number of commercially available probes even have integral and presterilized disposable product-contact surfaces. Included are probes for temperature, pH, and O2, CO2, pressure, and cell-mass. Many are compatible with Object Linking and Embedding (OLE) for Process Control (OPC) and compliant with 21 CFR part 11 digital automation systems. New sensing technologies being applied to SUS or SUS-compatible probes include fluorescence, capacitance, sensor-patch, and various infrared (IR) analyses (22). Cell-free sampling ports and interfaced autosamplers with demonstrated SUS utility support integration of the same instruments used in traditional glass and steel reactors.

Coupling and Transfer

A number of solutions are now commercially available to address the challenge of connectivity. From hybrid disposable-compatible connectors to fully disposable genderless connector systems to in-line welding, process designers have an increasing diverse pool of approaches from which to choose. Although the issue has been resolved for many implementations, challenges remain in regard to particular scales, flow rates, and process conditions.

Environmental Footprint

Initial reactions of many people are that systems reliant on “disposable plastic” components would be more detrimental to the environment than are classical systems. But on deeper examination, we find that many types of considerations arise.

First, SUS plastic waste must be compared with the many wastes generated by a classical system being replaced. Consider the fouled water disposal that follows clean-in-place (CIP) procedures and the fuel burned to generate steam for steam-in-place (SIP) systems.

Second, the distinct and divergent categories of “environmental stress” receive varying degrees of concern even from experts. For example, it is difficult to weigh the relative harm imposed by carbon generation against landfill use and water consumption (23).

A host of implementation-specific considerations include national, geographical, and economic imperatives introducing new factors such as regional standards on waste-water disposal. The industry has progressed to an understanding that easy answers are not apparent and that evaluation of the environmental stresses associated with any system, even at one moment in time, is a complex undertaking (24). A nonobvious example is the environmental impact of additional employees required for CIP systems operation, such as in their commuting (25).

Finally, consider the environmental impact of each component throughout its entire existence. Life-cycle analysis (LCA) examines the aggregate consequences of system components, not just during their use, but from manufacture to disposal (26). All things considered, most conclusions support acceptabi

lity for the relative ecological consequences of SUS (27).

QbD and PAT

Concurrent with SUS, the industry is adopting such initiatives as quality by design (QbD) and process analytical technology (PAT). It turns out that many features of SUS actively support both: e.g., modularity, reconfigurablity, flexibility in process flow and layout, and improved compliance values. Whether SUS are applied at process development or full manufacturing scale, their features support these new regulatory initiatives through development of increased process understanding and improved process life-cycle management (3).

Flexibility

Support of so-called flexible manufacturing under CGMP compliance has emerged as a hallmark of SUS-based manufacturing. Economic, regulatory, and market pressures create a demand to include “flexibilities” in biomanufacturing process design: e.g., efficient accommodation of changes in campaign schedules, production scale, and system reconfiguration in support of multiple product portfolios — even to support the active use of multiple production platforms. Although such power is remarkable in itself, the concept of flexible manufacturing also confers the efficient support over a product’s life cycle of improvements in certain unit operations and even the replication or relocation of entire facilities.

Many flexible features of disposables support even further capabilities or economy. For example, the ease with which a manufacturing process based on SUS can be replicated at a second location facilitates the use of a CMO for production at early stages or in high-risk ventures, allowing the exact process to be readily transferred to a sponsor’s facility when the product reaches a more advanced stage. The promise of such capabilities has not only been demonstrated in a number of real-life SUS implementations, but also has become a major theme in modern biomanufacturing process design (9,28).

Performance

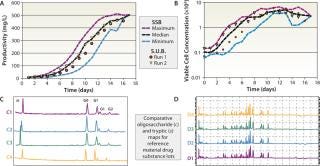

Many SUS have by now demonstrated the performance they initially promised (Figure 2). Although most disposable mixers and bioreactors on the market are distinct engineering solutions, for example, the performance of many have been established through years of application. Wave-style bioreactors have been used in actual API production seed trains for over five years. Newer stirred-tank SUS reactors have demonstrated excellent performance through peer-reviewed case studies and conference presentations (22,29). Surprisingly, it is not uncommon to find performance of disposables to be even superior to classical systems (30). The era of single-use based biomanufacturing has arrived, and many more advanced systems are currently used to manufacture products now in clinical trials.

Figure 2: ()

About the Author

Author Details

William G. Whitford is senior bioprocessing market manager at Thermo Fisher Cell Culture and Bioprocessing, 925 West 1800 South Logan, UT 84321; 1-435-792-8277; [email protected].

REFERENCES

1.) Eibl, R, and D. Eibl. 2010.Single-Use Technology in Biopharma Manufacturing, John Wiley, Somerset.

2.) Caine, B. The Impact of Single-Use Technologies.

3.) Rao, G, A Moreira, and K. Brorson. 2009. Disposable Biotechnology: The Time Has Arrived. Biotechnol. Bioeng 102:348-356.

4.) Odum, J. Flickinger, M 2010.Closed Systems in BioprocessingEncyclopedia of Industrial Biotechnology: Bioprocess, Bioseparation, and Cell Technology, John Wiley, Somerset.

5.) Sinclair, A, and M. Monge. 2010. Measuring Manufacturing Cost and Its Impact on Organizations. BioProcess Int. 8:10-15.

6.) Petrides, D, and C. Siletti. 2010.The Impact of Single-Use Systems (Disposables) on Cleaning Materials, Cost of Goods, and the Environment: A Case Study Involving MAb Production GreenBioPharma, BioConferences International, Inc., Philadelphia.

7.) Kapp, T, SA Montgomery, and K. Ott. 2010. Road Map to Implementation of Single-Use Systems: A BPSA White Paper for Manufacturing Decision-Makers within End-User Organizations. BioProcess Int. 8:S10-S19.

8.) Ozturk, S. 2008.Implementing Disposable Technologies to Commercial Biomanufacturing Facilities: Challenges, Opportunities, and Strategies BioProcess International European Conference and Exhibition, IBC Life Sciences, Vienna.

9.) Muller, R. 2008.Enabling Platform Technologies BioProcess International European Conference and Exhibition, IBC Life Sciences, Vienna.

10.) De Palma, A. 2010. Single-Use Becoming an Established Tool. Gen. Eng. News 30.

11.) Eibl, R. 2010. Disposable Bioreactors: The Current State-of-the-Art and Recommended Applications. Appl. Microbial Biotechnol. 86:41-49.

12.) Scott, C. 2007. Single-Use Bioreactors: A Brief Review of Current Technology. BioProcess Int. 5:44-51.

13.) Zhou, J. 2008.Effective Incorporation of Disposables into MAb DSP BioProcess International European Conference and Exhibition, IBC Life Sciences, London.

14.) Jiang, H. 2010.Purification of H5N1 and H1N1 VLP-Based Vaccines Single-Use Applications for Biopharmaceutical Manufacturing, IBC Life Sciences, Westborough.

15.) Sinclair, A, and M. Monge. 2010. End-to-End Deployment of Single-Use Technology in Aseptic Filling of Vaccines at GSK. BioPharm Int 23.

16.) Extractables and Leachables Subcommittee of the Bio-Process Systems Alliance 2008. Recommendations for Extractables and Leachables Testing. BioProcess Int. 6:S28-S39.

17.) PQLI Biotechnology Task Team International Society for Pharmaceutical Engineering.

18.) Fernald, A. 2009. Scale-Up and Comparison Studies Evaluating Disposable Bioreactors and Probes. BioPharm Int.

19.) Legmann, R. 2009. A Predictive High-Throughput Scale-Down Model of Monoclonal Antibody Production in CHO Cells. Biotechnol. Bioeng. 104:1107-1120.

20.) Roth, G. 2010. Single-Use Technologies and Trends. Contract Pharma 12:50-53.

21.) Valentine, D. 2010.Evaluation and Implementation of Cutting Edge Sensors Single-Use Applications for Biopharmaceutical Manufacturing, IBC Life Sciences, Westborough.

22.) Melling, P, and M. Thomson Fermentation Process Monitoring II: Mammalian Cell Culture. BioPharm Int white paper. http://biopharminternational.findpharma.com/biopharm/Article/ArticleStandard/Article/detail/655720.

23.) Disposals Subcommittee of the Bio-Process Systems Alliance 2007. Guide to Disposal of Single-Use Bioprocess Systems. BioProcess Int 5:22-28.

24.) Sinclair, A. 2008. The Environmental Impact of Disposable Technologies. BioPharm Int. 21:S4-S15.

25.) Leveen, L. 2009. Single-Use Technology and the Carbon and Water Footprints of Biopharm Manufacturing. Am. Pharmaceut. Rev:72-78.

26.) Matuer, M. 2009. Environmental Life-Cycle Assessment of Disposable Bioreactors. BioProcess Int. 7:S18-S29.

27.) Flaherty, W. 2010.Disposing of Disposables and Related Environmental Concerns Single-Use Applications for Biopharmaceutical Manufacturing, IBC Life Sciences, Westborough.

28.) Rios, M. 2010. Special Report: Flexible Manufacturing. BioProcess Int. 8:34-47.

29.) Richieri, R. 2010.Side By Side Comparison of the 1,000-L S.U.B. vs. 1,000-L Stainless Steel Bioreactor Single-Use Applications for Biopharmaceutical Manufacturing, IBC Life Sciences, Westborough.

30.) Nicolas, S. 2010.Scale-Up of a Large Disposable Vaccine Manufacturing Process: Microcarrier Culture, Facility and Economics Considerations Single-Use Applications for Biopharmaceutical Manufacturing, IBC Life Sciences, Westborough.

You May Also Like